led automatic feeding machine

A technology of automatic feeding and racking, which is applied to conveyor objects, electrical components, circuits, etc., can solve the problems of low efficiency and labor consumption, and achieve the effect of multiple economic benefits, reduced labor costs, and reduced labor consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

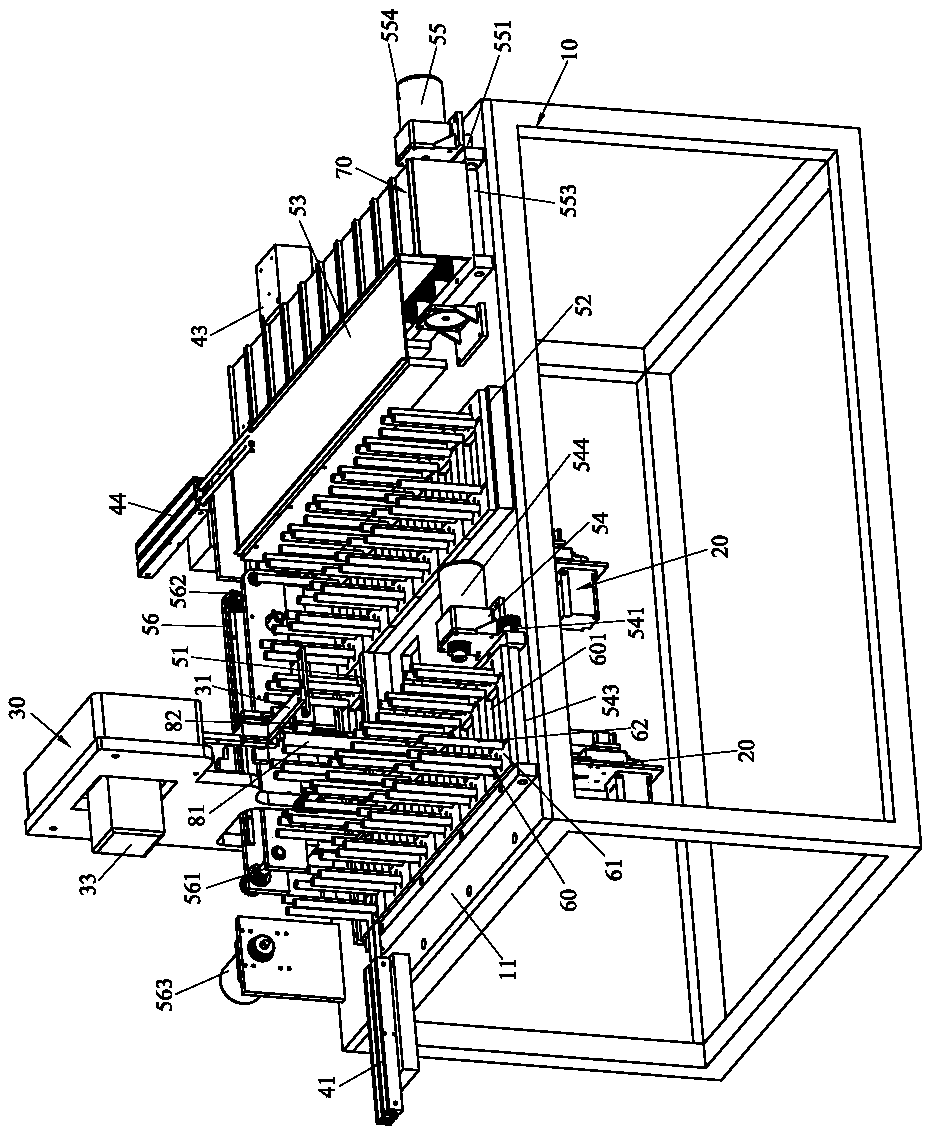

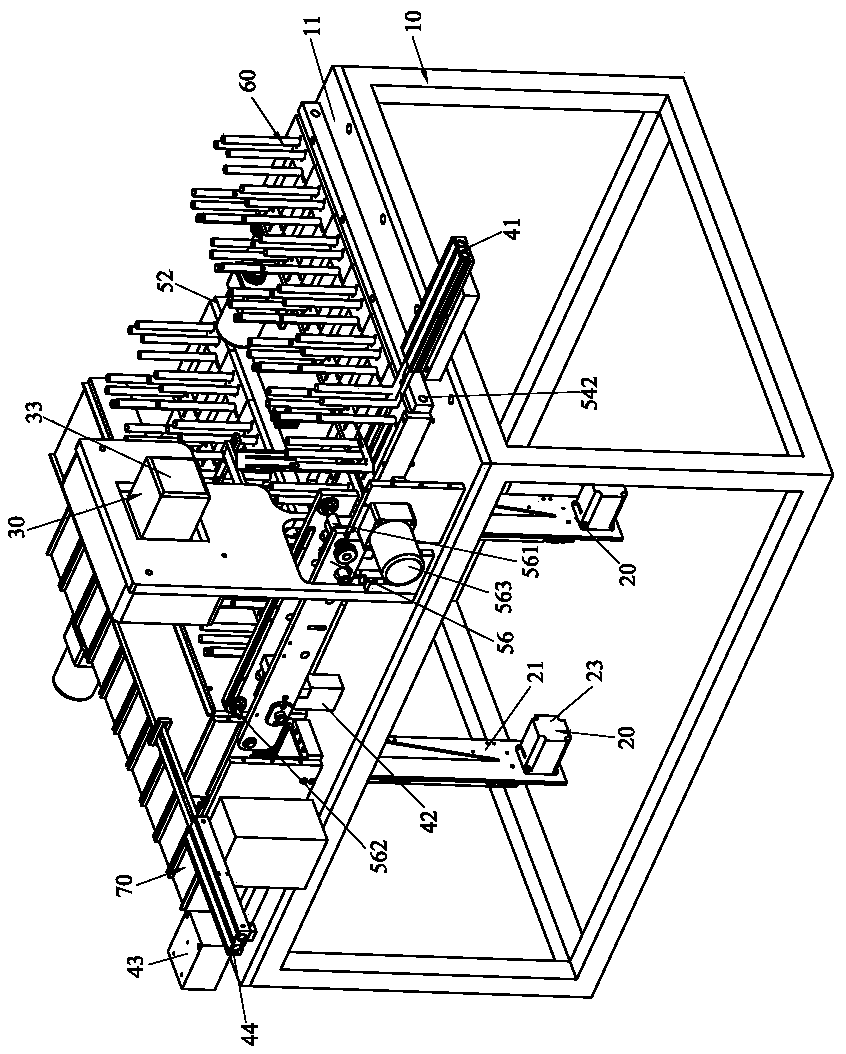

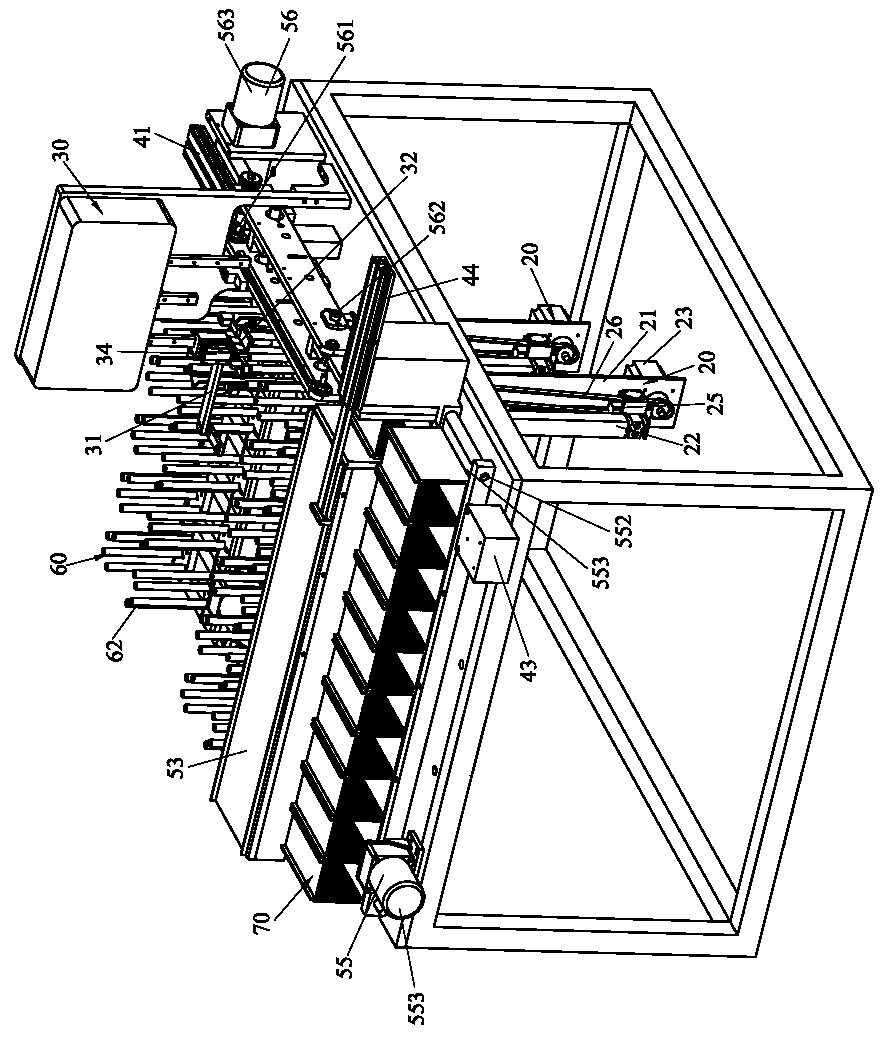

[0058] Please refer to Figure 1 to Figure 8 Shown, it has shown the concrete structure of preferred embodiment of the present invention, comprises a frame 10, two hoisting mechanisms 20, a moving mechanism 30, a first pushing mechanism 41, a second pushing mechanism 42, a first Three pushing mechanisms 43 and a fourth pushing mechanism 44.

[0059] The frame 10 has a workbench 11, the workbench 11 is provided with a first through groove 101, a second through groove 102 and a blanking chute, and the surface of the workbench 11 is provided with a transverse conveying groove 51 and a first longitudinal conveying groove 52 , the second longitudinal conveying trough 53, the first longitudinal conveying mechanism 54 for conveying the placement frame 60, the second longitudinal conveying mechanism 55 for conveying the placement box 70, and the transverse conveying mechanism for conveying the LED sheet (not shown in the figure) Conveying mechanism 56; the transverse conveying trough...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com