Method for determining heat power consumption of satellite-borne active phased-array antenna assembly based on electromechanical coupling

A phased array antenna, electromechanical coupling technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the cumbersome process, can not directly estimate the degree of thermal power consumption of components on electrical performance, time-consuming And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

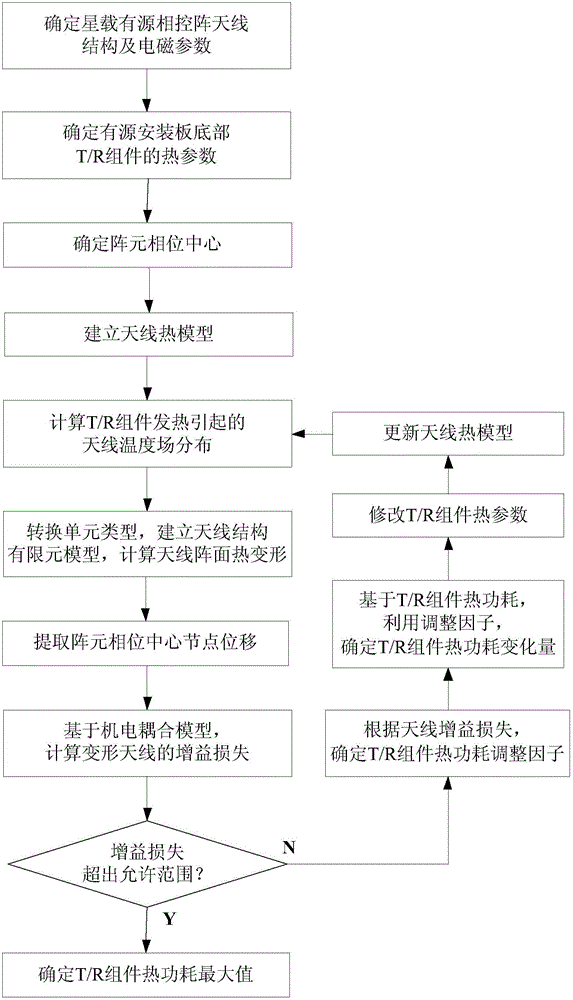

[0072] refer to figure 1 , the present invention is based on electromechanical coupling space-borne active phased array antenna component thermal power consumption determination method, the specific steps are as follows:

[0073] Step 1. Determine the structural parameters, material properties and electromagnetic parameters of the spaceborne active phased array antenna

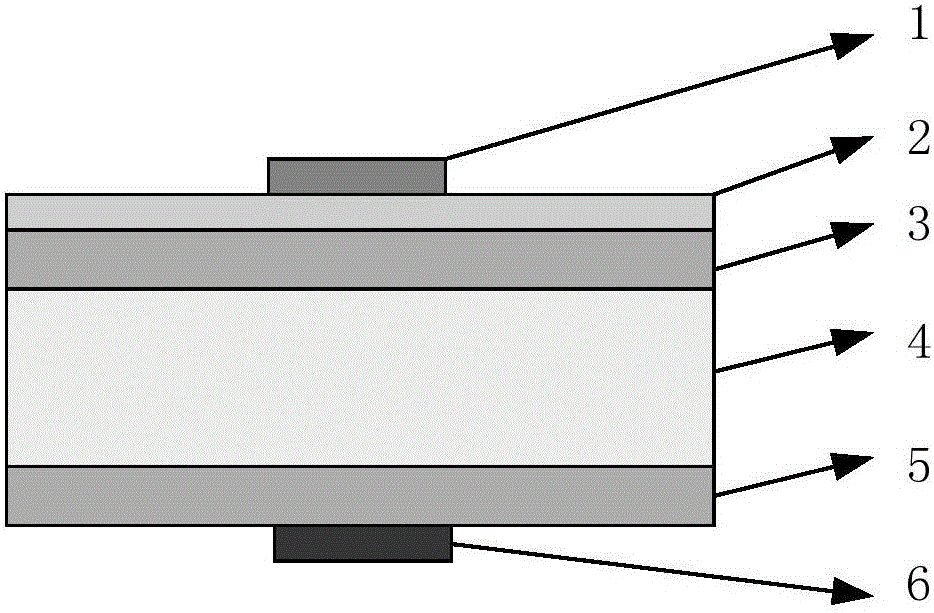

[0074] See the geometric model of spaceborne active phased array antenna figure 2 As shown, the structural parameters of the spaceborne active phased array antenna include antenna unit 1, substrate 2, active mounting plate (aluminum honeycomb upper panel 3, aluminum honeycomb 4, aluminum honeycomb lower panel 5), heat source (T / R assembly 6) The length, width and height of the antenna, as well as the number of rows, columns and unit spacing of the antenna arrangement; material properties in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com