Arc test device

A test device and arc technology, applied in the direction of measuring device, circuit breaker testing, measuring electricity, etc., can solve the problem of inability to observe the arc shape and other problems, and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

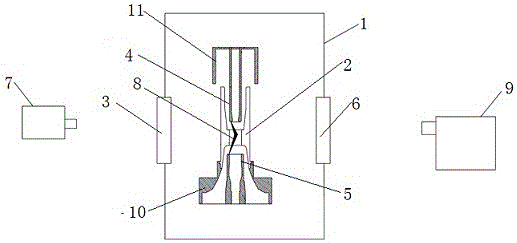

[0014] The embodiment of arc test device among the present invention is for example figure 1 shown. The arc test device includes a closed chamber 1, and the closed chamber 1 is provided with a static arc contact 4, a moving arc contact 5 and a nozzle 2 that moves with the moving arc contact 5, a static arc contact 4 and a moving arc contact. 5 are arranged up and down relative to each other in the closed chamber 1. The spout 2 is a transparent spout, and when the static and dynamic arc contacts are in the opening state, the end of the static arc contact 4 is located in the spout 2 . The size and shape of the nozzle 2 can be designed and manufactured completely according to the size and shape of the real nozzle in the actual circuit breaker, so the arc test research using the arc test device is closer to the real situation, and the test results will be more accurate. The spout 2 is made of plexiglass, which can withstand the high temperature and high pressure generated when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com