Experiment loading device for realizing large-size model multipoint load distribution

A loading device, large-scale technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of uneven load, time-consuming, uneconomical design, etc., to reduce the number of load-bearing frames and jacks, The effect of high material utilization and economy, and simplified test loading process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

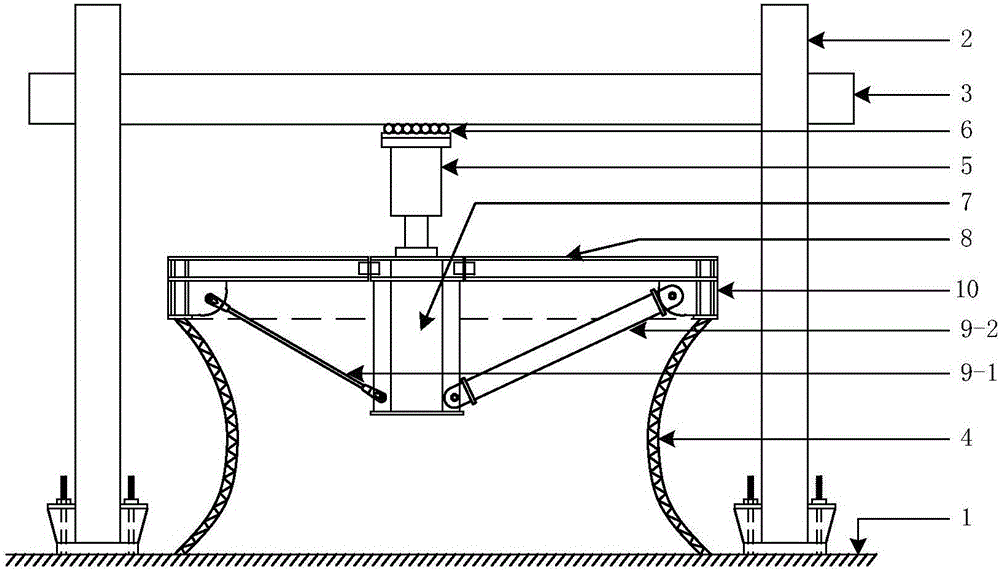

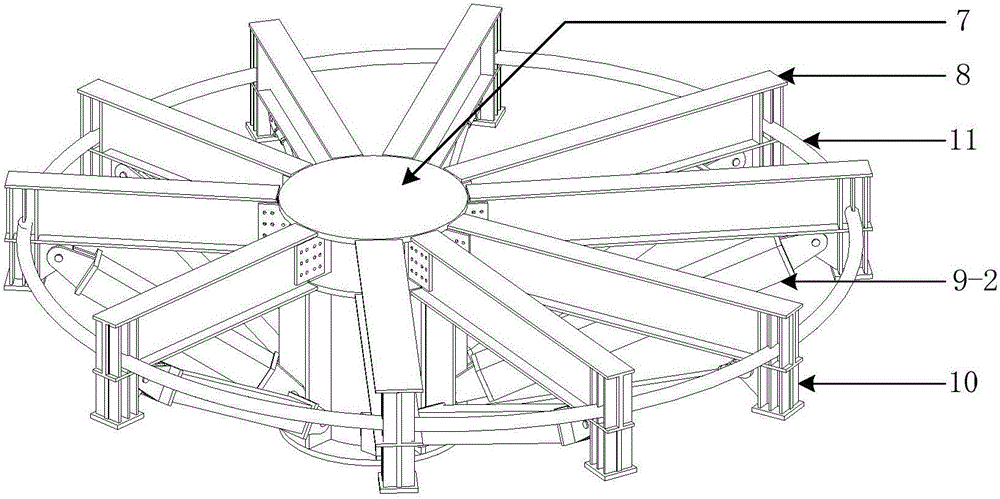

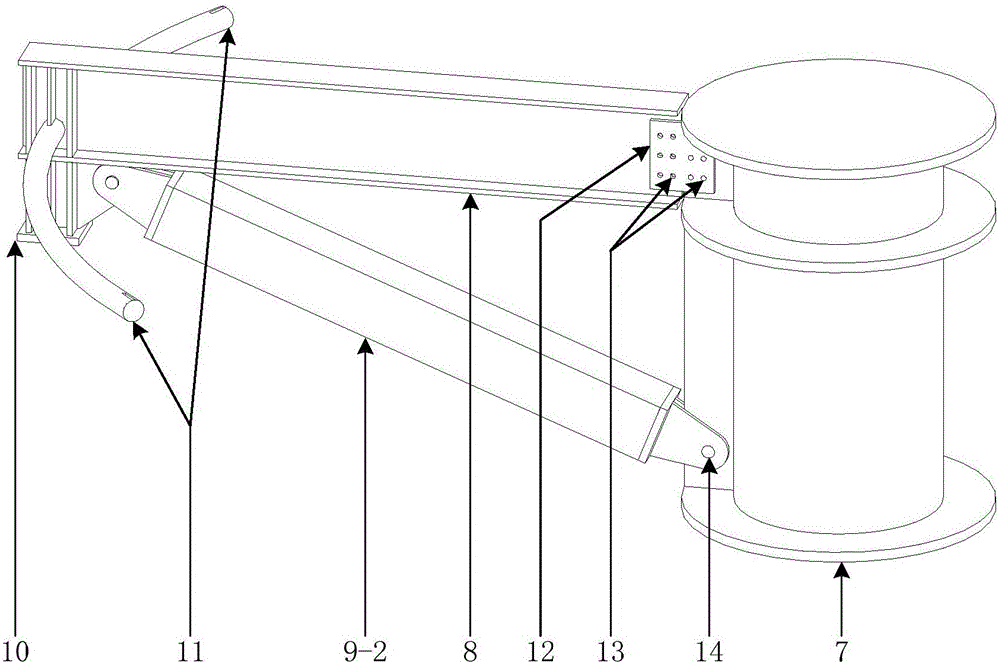

[0025] Attached below Figure 1-9 , to describe the implementation of the present invention in detail.

[0026] Such as Figure 1~2 As shown, a test loading device capable of realizing multi-point load distribution of large-scale models includes the following components:

[0027] 1——Test bench;

[0028] 2——bearing column;

[0029] 3 - bearing beam;

[0030] 4——Large grid cylinder test specimen;

[0031] 5 - Jack;

[0032] 6——horizontal sliding support;

[0033] 7 - fly column;

[0034] 8—radial beam;

[0035] 9—diagonal tie rod, including two forms: 9-1—high strength steel tie rod, 9-2—section steel or welded section member;

[0036] 10——load short column;

[0037] 11—circular support.

[0038] Such as figure 1 As shown, the test loading device capable of realizing multi-point load distribution of a large-scale model is composed of a bearing system, a loading system and a load distribution system. The load-bearing system includes a test bench 1, a load-bearing col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com