Speed reducer

A technology of reducer and planetary gear, which is applied in the direction of mechanical equipment, gear transmission, belt/chain/gear, etc., can solve the problems of low input speed, difficulty in large torque transmission, difficulty in large reduction ratio, etc., and achieve low cost , high reliability, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

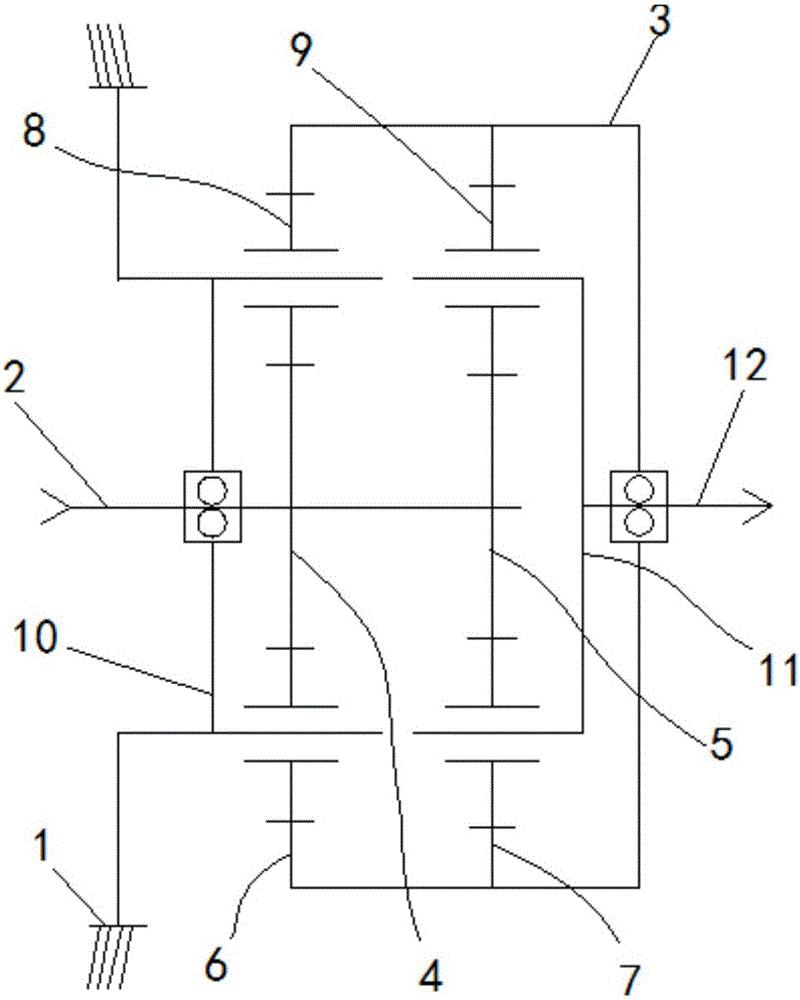

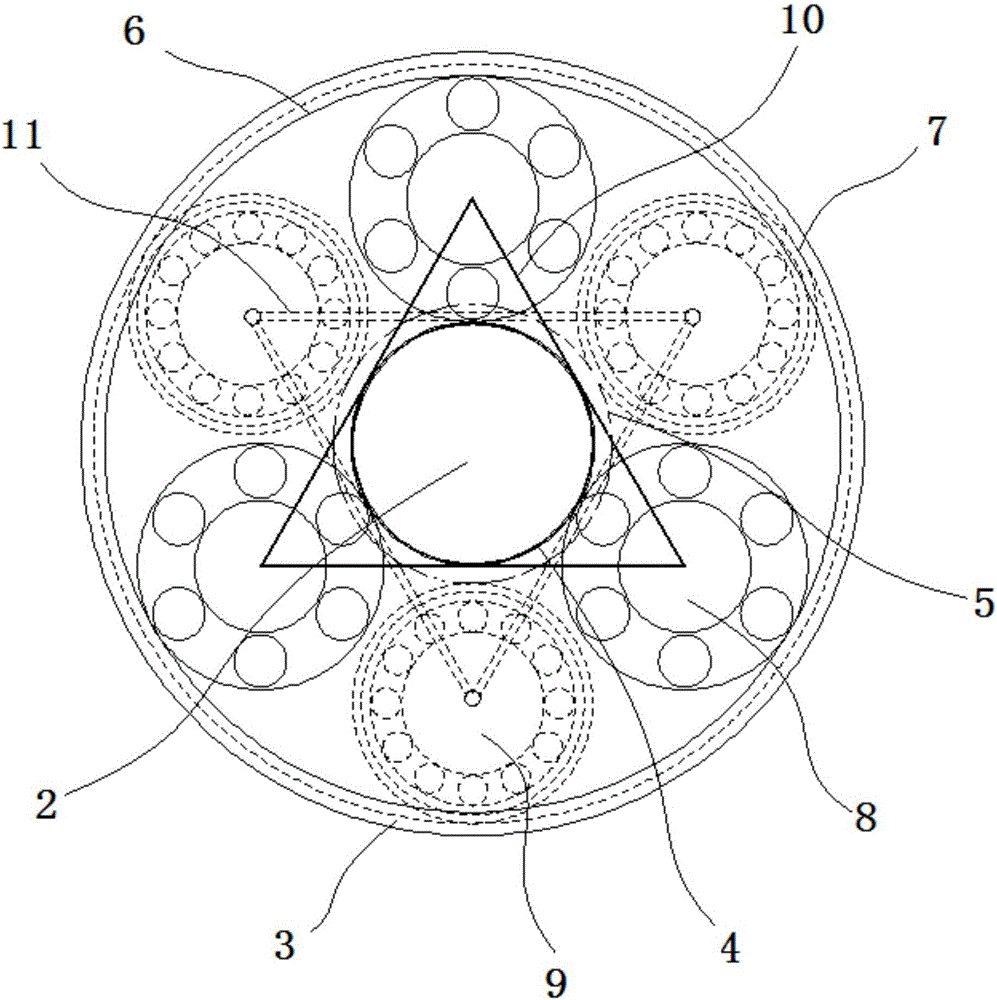

[0023] See figure 1 and figure 2 , a speed reducer, including a housing 1, an inner ring 2 arranged in the housing 1 and an outer ring 3 arranged on the periphery of the inner ring 2, and the outer wall of the inner ring 2 includes a first sun gear 4 and a second sun gear 5, the inner wall of the outer ring 3 contains a first ring gear 6 and a second ring gear 7, a set of first planetary gears 8 are meshed between the first sun gear 4 and the first ring gear 6, and the second A set of second planetary gears 9 is meshedly connected between the sun gear 5 and the second ring gear 7, a set of first planetary gears 8 is positioned and connected inside the first ring gear 6 through the first planetary gear cage 10, and a set of The second planetary gear 9 is positioned and connected inside the second ring gear 7 through the second planetary gear cage 11, and the second planetary gear cage 11 is fixedly connected with a transmission shaft 12; wherein, the first planetary gear cage...

Embodiment 2

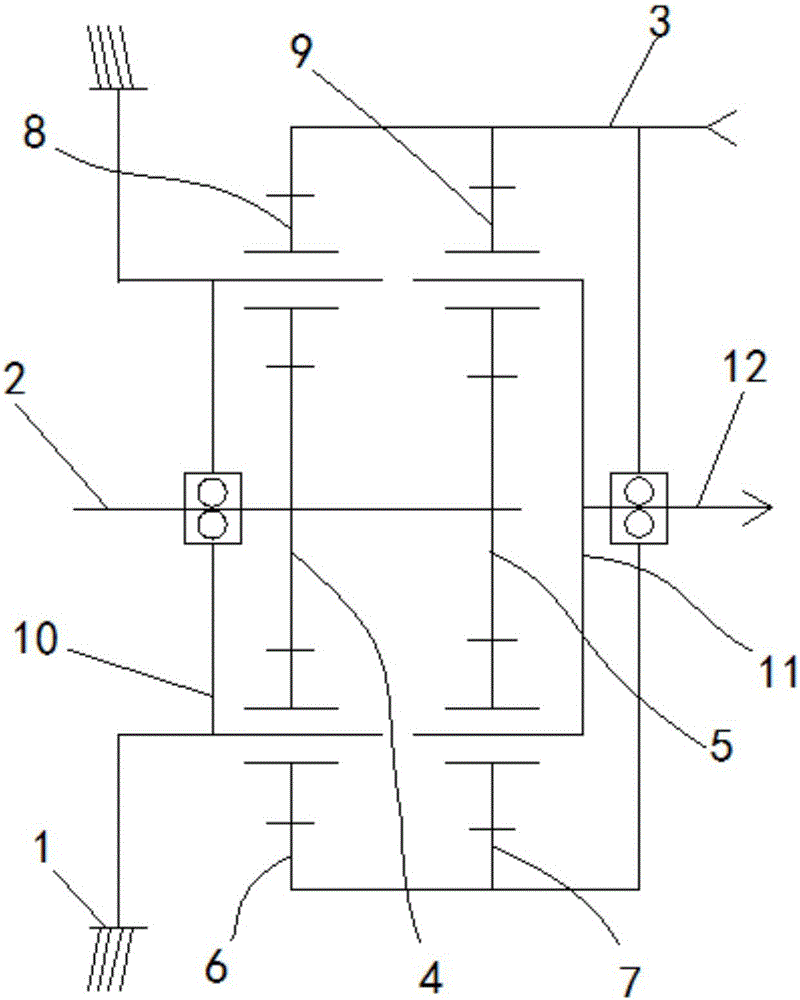

[0030] See image 3 , a speed reducer, including a housing 1, an inner ring 2 disposed in the housing 1 and an outer ring 3 disposed on the periphery of the inner ring 2, the outer wall of the inner ring 2 includes a first sun gear 4 and a second The sun gear 5 includes a first ring gear 6 and a second ring gear 7 on the inner wall of the outer ring 3, and a set of first planetary gears 8 are engaged and connected between the first sun gear 4 and the first ring gear 6, A set of second planetary gears 9 is meshedly connected between the second sun gear 5 and the second ring gear 7, and a set of first planetary gears 8 is positioned and connected inside the first ring gear 6 through the first planetary gear cage 10. A set of second planetary gears 9 is positioned and connected inside the second ring gear 7 through a second planetary gear cage 11, and the second planetary gear cage 11 is fixedly connected with a transmission shaft 12; wherein, the first planetary gear cage 10 Wh...

Embodiment 3

[0033] See Figure 4 , a speed reducer, including a housing 1, an inner ring 2 disposed in the housing 1 and an outer ring 3 disposed on the periphery of the inner ring 2, the outer wall of the inner ring 2 includes a first sun gear 4 and a second The sun gear 5 includes a first ring gear 6 and a second ring gear 7 on the inner wall of the outer ring 3, and a set of first planetary gears 8 are engaged and connected between the first sun gear 4 and the first ring gear 6, A set of second planetary gears 9 is meshedly connected between the second sun gear 5 and the second ring gear 7, and a set of first planetary gears 8 is positioned and connected inside the first ring gear 6 through the first planetary gear cage 10. A set of second planetary gears 9 is positioned and connected inside the second ring gear 7 through a second planetary gear cage 11, and the second planetary gear cage 11 is fixedly connected to a transmission shaft 12; wherein, the outer ring 3 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com