Rotor Blade Extension Part

A rotor blade and extension technology, applied in the field of rotor blade extension, to reduce the risk of leading edge erosion, improve aerodynamic characteristics, and eliminate the impact of aerodynamic noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

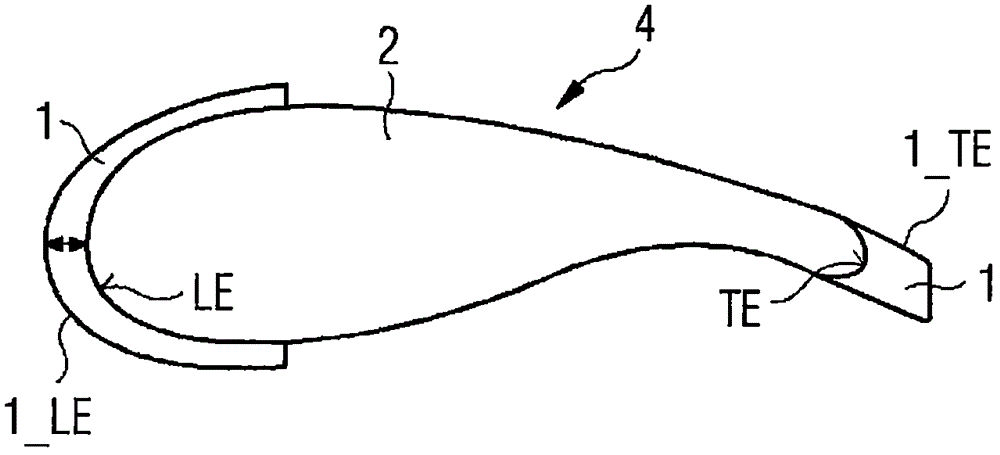

[0045] figure 1 An outboard portion of an extended rotor blade 4 of a wind turbine 3 is shown. The extended rotor blade 4 comprises a first embodiment of the rotor blade extension 1 according to the invention in position on the tip 20 of the rotor blade 2 . The rotor blade 2 comprises a trailing edge TE and a leading edge LE. The rotor blade 2 is tapered, ie pointed, and includes a tip 20 . Reference numeral 20 designates the tip of the "raw" rotor blade 2 , ie the tip of the rotor blade 2 without any rotor blade extension. Once the rotor blade extension 1 is attached to the rotor blade 2, an extended rotor blade 4 is obtained. Reference numeral 21 designates the tip of the extended rotor blade 4 , which is therefore also referred to as “extended tip” 21 .

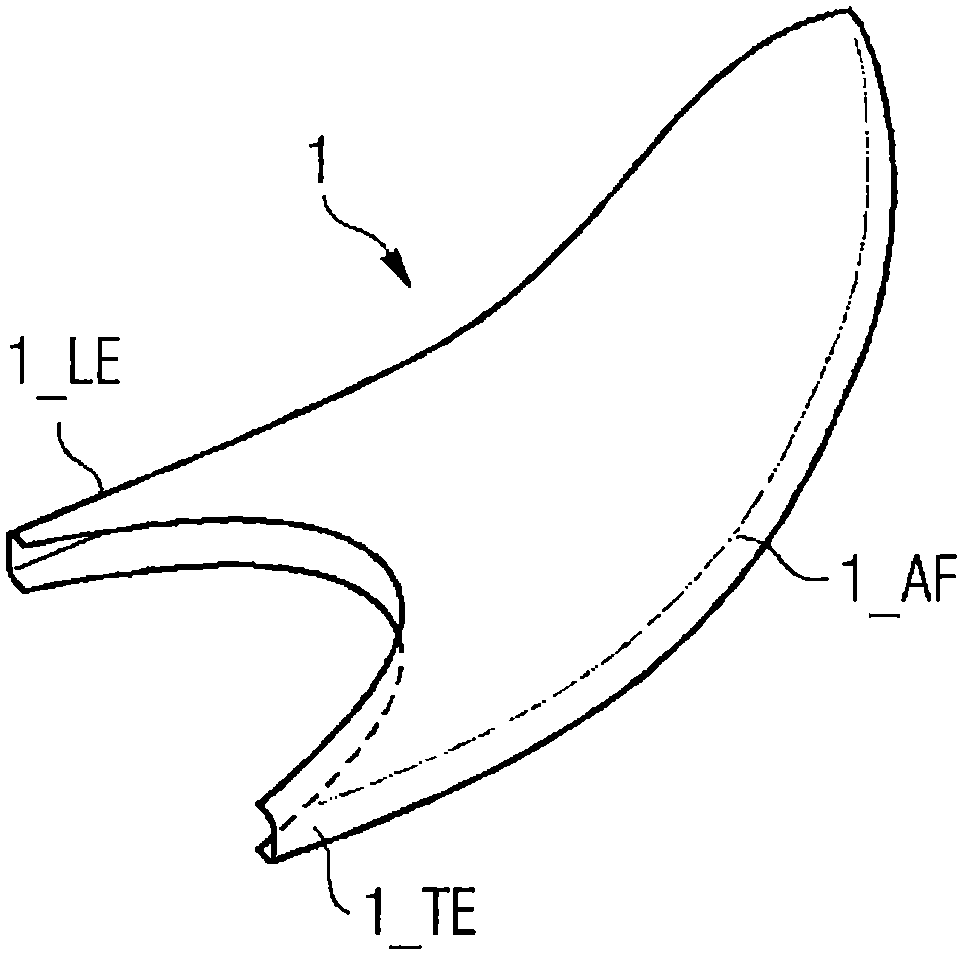

[0046] The rotor blade extension 1 is shown to comprise: an airfoil extension part 1_AF, which effectively extends the length of the rotor blade 2; a leading edge part 1_LE, which is used to cover or extend a part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com