Fireproof and explosion-proof door

A technology of explosion-proof doors and door bodies, which is applied in the field of explosion-proof doors and fire prevention. It can solve the problems of short service life, thick plates, and single structure of explosion-proof doors, and achieve the effects of improving service life, prolonging survival time, and enhancing explosion-proof strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

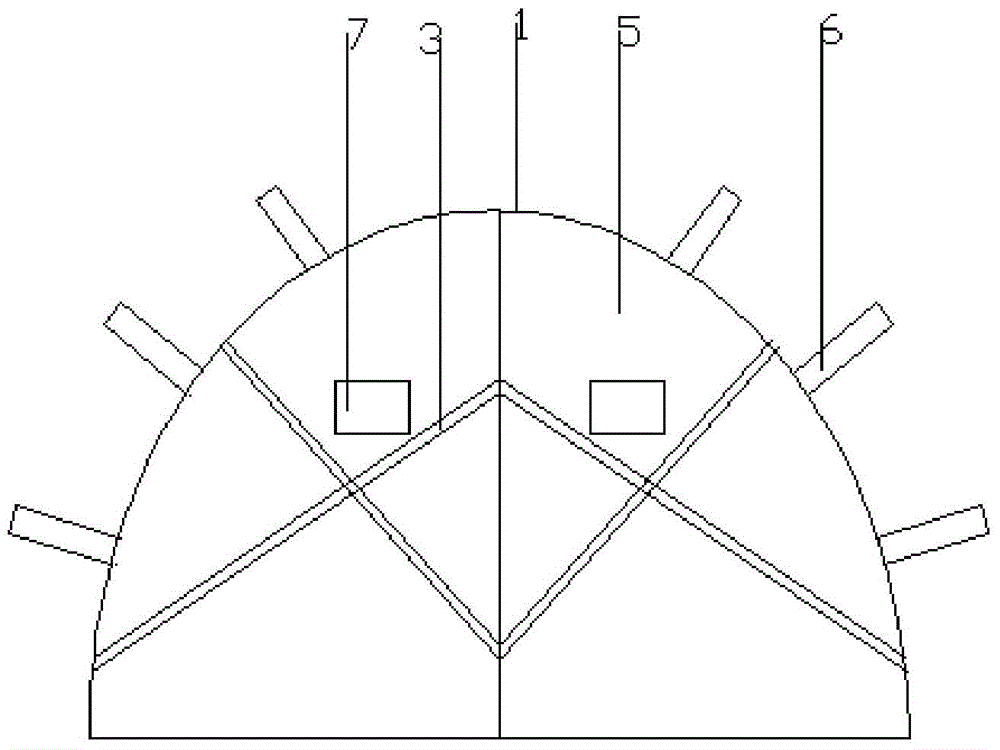

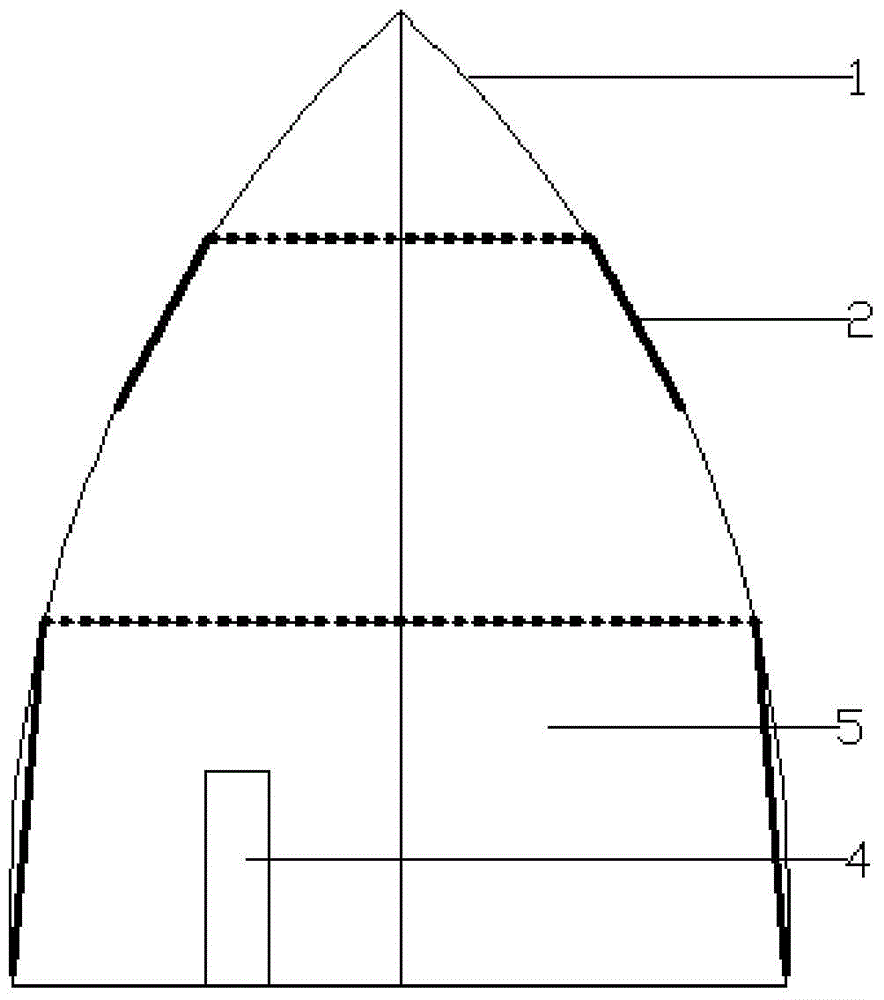

[0014] Such as figure 1 , figure 2 As shown, a fire-proof and explosion-proof door includes an olive-shaped door body 1, supporting ribs 2, reinforcing ribs 3 and oxygen increasing device 4, and the olive-shaped door body 1 forms a cavity 5, and the inner wall of the cavity 5 is provided with More than one pin shaft and hasp, the oxygen increasing device 4 is located in the cavity 5, the reinforcing rib 3 is provided on the panel of the olive-shaped door body 1, and the two reinforcing ribs 3 are intersected on the On the panel of each olive-shaped door body 1, one end of the support rib 2 is provided with a ball bearing, and the ball bearing is mated with the pin shaft, and the other end is clamped on the hasp.

[0015] More than one catch 6 is provided on the periphery of the olive-shaped door body 1 .

[0016] The olive-shaped door body 1 is provided with an explosion-proof window 7 .

[0017] A fire-proof and explosion-proof door. The olive-shaped door body 1 forms a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com