A reed moving raising mechanism

A technology of raising mechanism and reed movement, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems affecting the stability of looms, safety performance, short service life of the pendulum rod, and large force on the pendulum rod. The effect of stable weft, small maintenance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

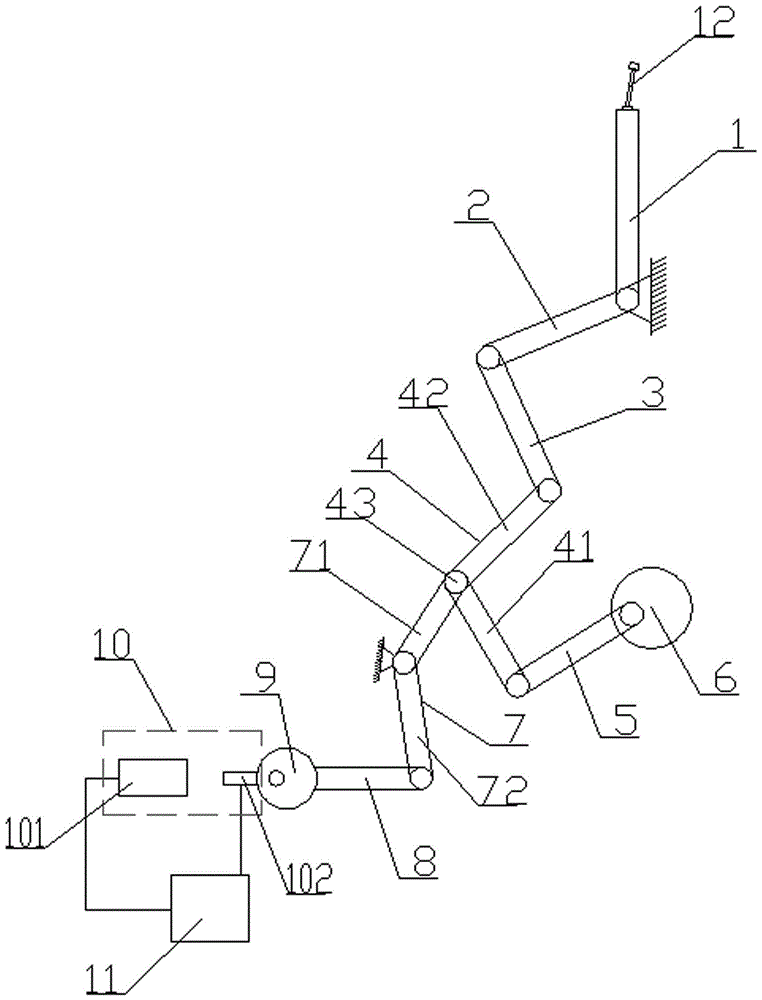

[0015] figure 1 Middle: A reed moving fluffing mechanism includes reed 12, sley foot 1, sley foot drive lever 2, sley foot drive link 3, fixed angle reversing lever group 4, power rod drive link 5, eccentric Driving mechanism 6, adjustable and fixed angle control rod group 7, eccentric connecting rod 8, numerical control actuator 9, origin signal acquisition mechanism 10 and control electric box 11, eccentric driving mechanism 6 hinged power rod driving connecting rod 5 at one end, power rod The other end of the drive link 5 is hinged to one end of the first power rod 41 of the reversing rod group 4 at a fixed angle, and the other end of the first power rod 41 is connected to one end of the second power rod 42 at an adjustable fixed angle and has a power rod hinge point 43. The other end of the second power rod 42 is hinged to one end of the sley foot drive link 3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com