Electric wire splitting device for steel wire

An electric wire-separating and wire-splitting technology, which is applied in the directions of transportation and packaging, conveying filamentous materials, and thin-material processing, etc., can solve the problem of not allowing the wire to be paralleled, lapped and agitated, and the wire is not sufficiently heated, which affects the sliver. Mechanical properties and other issues, to achieve the effect of saving manpower, avoiding wire stirring, and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

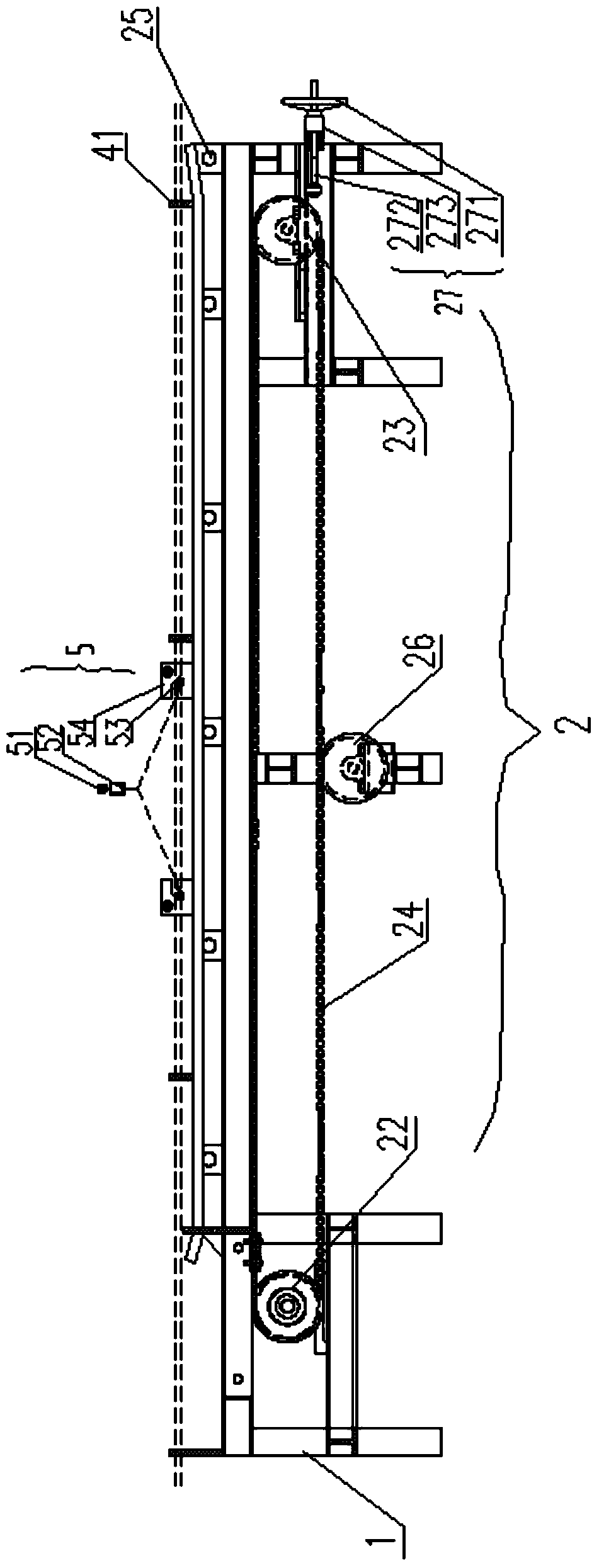

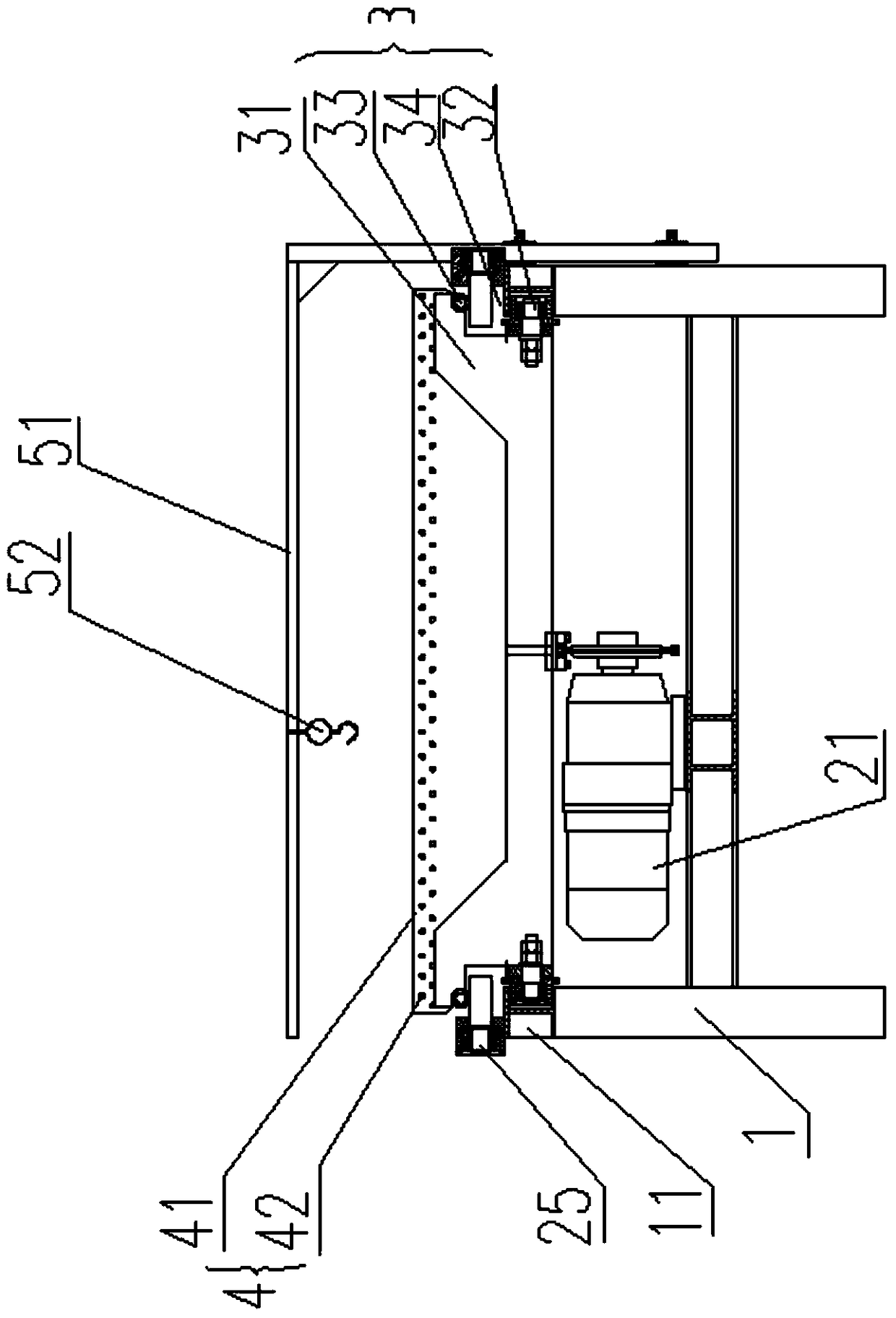

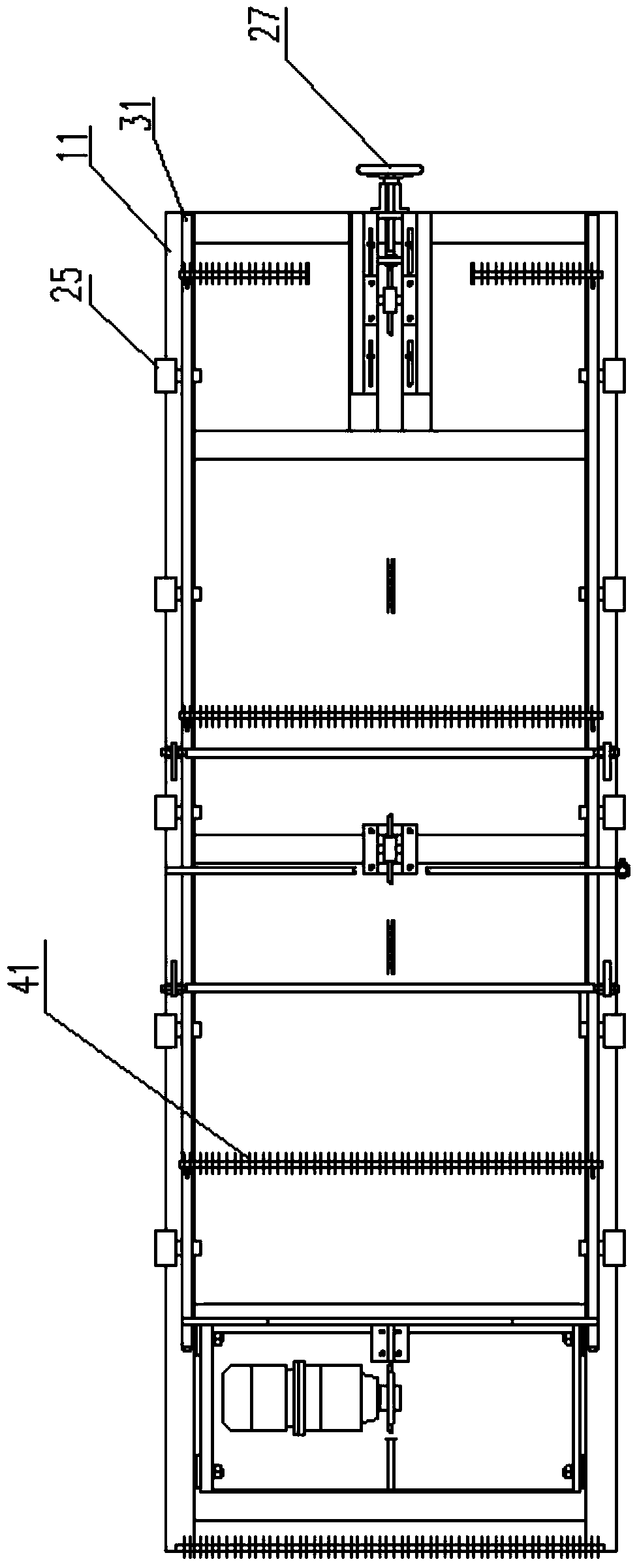

[0022] Such as Figure 1-3 As shown, the electric wire splitting device for steel wire of the present invention includes a frame 1 , a driving mechanism 2 , a wire guide mechanism 3 , a wire splitting mechanism 4 and a tension testing mechanism 5 .

[0023] Two guide rails 11 oppositely arranged are fixedly installed on the frame 1 . The driving mechanism 2 includes a motor 21 , a driving wheel 22 , a driven wheel 23 , a driving chain 24 , a guide roller 25 , a supporting sprocket 26 and a tensioning device 27 . The motor 21 and the drive wheel 22 are fixedly mounted on one end of the guide rail 11, and the motor 21 is electrically connected to the drive wheel 22, the driven wheel 23 is fixedly mounted on the other end of the guide rail 11, and the drive chain 24 is wound around the drive wheel 22 and the driven wheel 23, The suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com