Insulation paper rewinding device

A technology of insulating paper and power device, which is applied in the direction of winding strip, transportation and packaging, thin material processing, etc., can solve the problems of poor winding effect, continuous work without stopping, low efficiency of manual winding, etc. Convenience, high rewinding tightness, fast rewinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

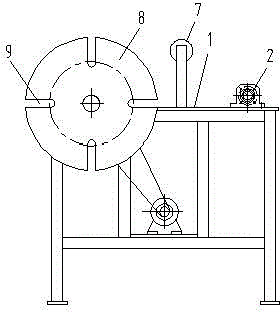

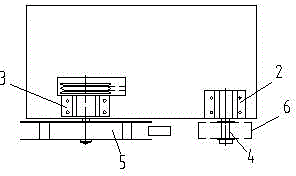

[0013] Such as figure 1 As shown, an insulating paper rewinding device includes a frame 1, a label insulating paper roll seat 2 arranged on the frame, a rewinding paper roll seat 3 and a power device. The standard insulating paper roll seat Roller I4 for placing standard insulating paper rolls is set on the top, and roll II5 for rewinding insulating paper is set on the rewinding paper roll stand. The driving pulley, the roll II and the driven pulley are set on the same rotating shaft, the rotating shaft is set on the rewinding paper roll seat through the bearing, and the roll I is also rotatably set on the label insulation paper through the bearing on the reel stand.

[0014] In this embodiment, before rolling the paper, the standard insulating paper roll 6 is first placed on the roll I, and then the insulating paper is manually pulled on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com