a printer

A technology of printers and print heads, applied in typewriters, printing, etc., can solve the problems of inconvenient maintenance, difficult replacement, poor printing quality, etc., and achieve the effect of convenient maintenance, convenient replacement, and prevention of excessive rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

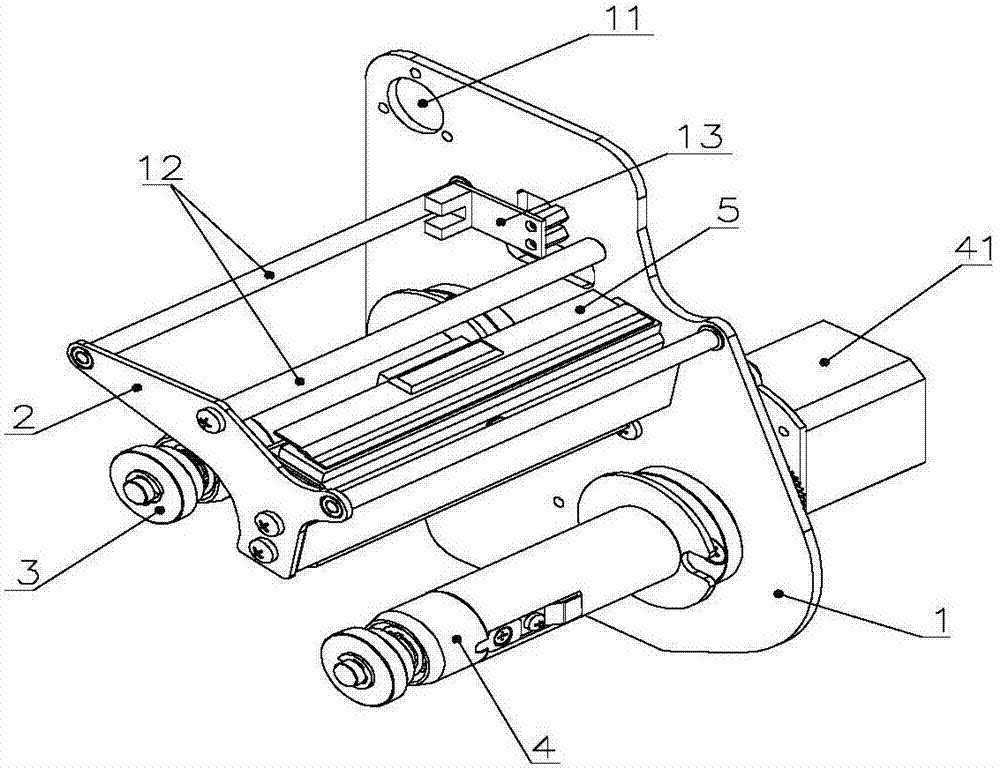

[0027] Such as figure 1 and figure 2 Shown, a kind of printer comprises installation board 1, fixed board 2, paper feeding shaft 3, recovery shaft 4, glue stick 6 and printing part 5, and the two ends of described printing part 5 are connected with installation board 1 and fixing board 2 respectively Fixedly connected, one end of the paper feeding shaft 3 and the recovery shaft 4 is installed on the mounting plate 1, the unused carbon ribbon is sleeved on the paper feeding shaft 3, and the used carbon ribbon is recovered through the recovery shaft 4. The printing part 5 includes a print head 51 and a buffer mechanism connected to each other. The buffer mechanism includes a fixed block 52, a guide bar 53 and a guide block 54. The two ends of the fixed block 52 are connected to the print head 51 and the guide bar 52 respectively. Fixedly connected, the guide rod 52 is sleeved in the guide block 54, the outer diameter of the guide rod 52 is smaller than the inner diameter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com