Cutting machine with hoisting curtains

A cutting machine and tape-reel technology, which is used in fur cutting, small raw hide/large hide/leather/fur mechanical processing, raw hide/leather/fur manufacturing equipment, etc. Expensive and other issues, to achieve the effect of reducing complexity and manufacturing costs, reducing use and maintenance costs, reducing power and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

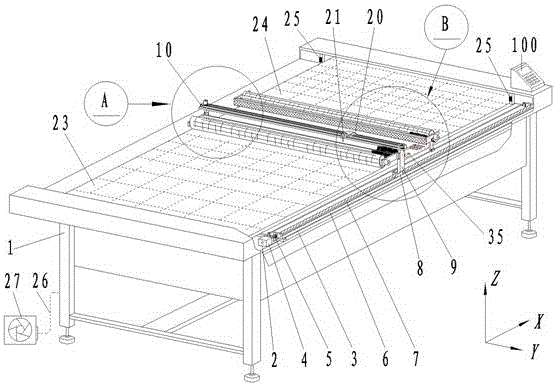

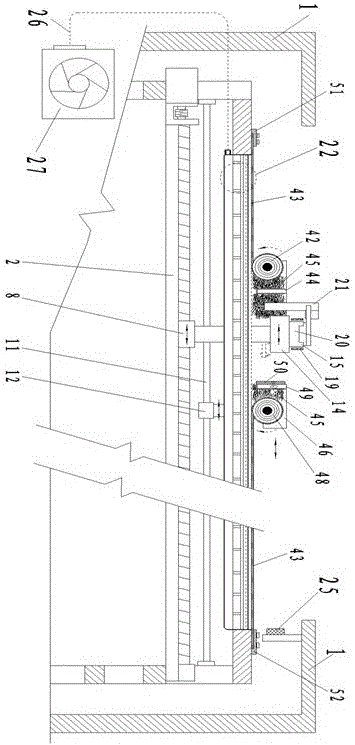

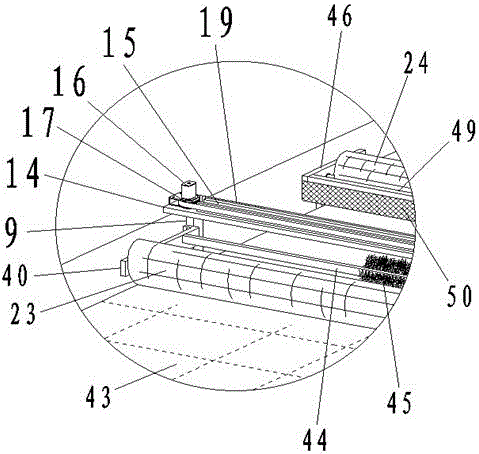

[0023] combine Figure 1 to Figure 6 , the cutting machine with hoisting curtain of the present invention includes a cutting machine frame 1, an X-axis driving module 2, a Y-axis driving module 10, an auxiliary X-axis guide rod 11, an auxiliary X-axis slider 12, and an auxiliary X-axis lug plate 13. Cutting head 21, platform 22, left hoisting curtain 23, right hoisting curtain 24, curtain clutch 35, pressure-resistant bellows 26, suction fan 27 and microcomputer 100.

[0024] The platform 22 is located above the frame 1 and is made up of an airtight cabin 28, a grid layer 30, a coarse-mesh grate layer 31, a fine-mesh grate layer 32, a sponge pad 33 and a non-woven fabric layer 34. The airtight cabin 28 The top is open and is provided with a grid layer 30, and the top of the grid layer 30 is successively provided with a coarse-mesh grate layer 31, a fine-mesh grate l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com