Oil cylinder removal device

A technology for dismantling a device and an oil cylinder, which is applied to metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of waste, difficulty in throwing away the oil cylinder, etc., and achieve the effects of reducing purchase cost, low cost, and convenient loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

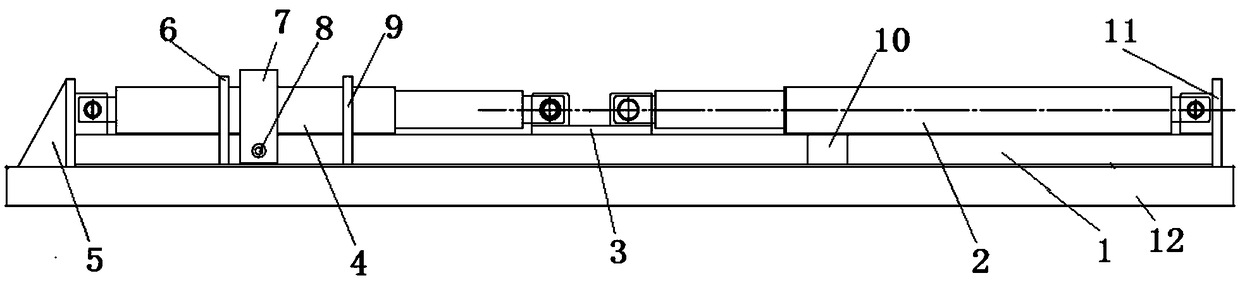

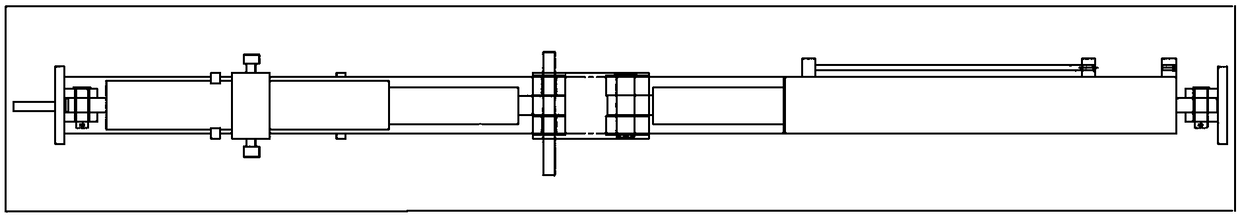

[0015] Such as Figure 1~2 As shown, the oil cylinder dismounting device includes a telescopic oil cylinder 2, the tail end of the telescopic oil cylinder 2 cylinder body is fixedly connected to one end of the base 1 through a fixed frame 11, and the free end of the telescopic oil cylinder 2 cylinder rod is provided with a slider 3. The block 3 has a pin hole for connecting the 4 cylinder rods of the dismantled oil cylinder, the base 1 is a bar-shaped groove structure, fixedly connected to the fixed platform 12, and the other end of the base 1 is provided with a fixing frame for connecting the 4 dismantled oil cylinders 2. 5. Connect the two ends of the waste and old dismantled oil cylinder to the fixed frame 2 5 and the slide block 3 respectively through pin shafts, and start the telescopic oil cylinder 2 to realize the disassembly of the waste and old oil cylinder. The disassembled oil cylinders are connected, and the other end of the dismantled oil cylinder is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com