A multi-pipe joint header welding device

A welding device and pipe joint technology, which is applied in the field of multi-pipe joint header welding deformation correction tooling, can solve problems that affect the quality of module tube panel assembly and welding, bending deformation, and affect the quality of module assembly on the heating surface, so as to achieve easy adjustment and elimination Welding deformation, the effect of ensuring the quality of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

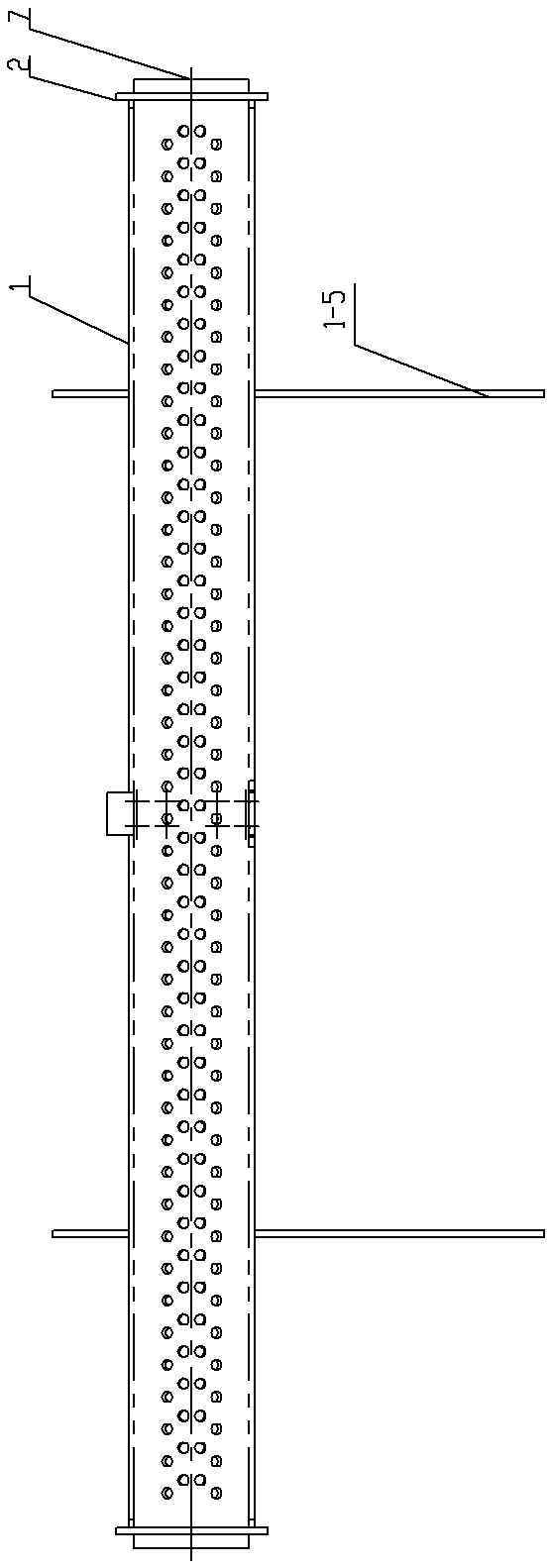

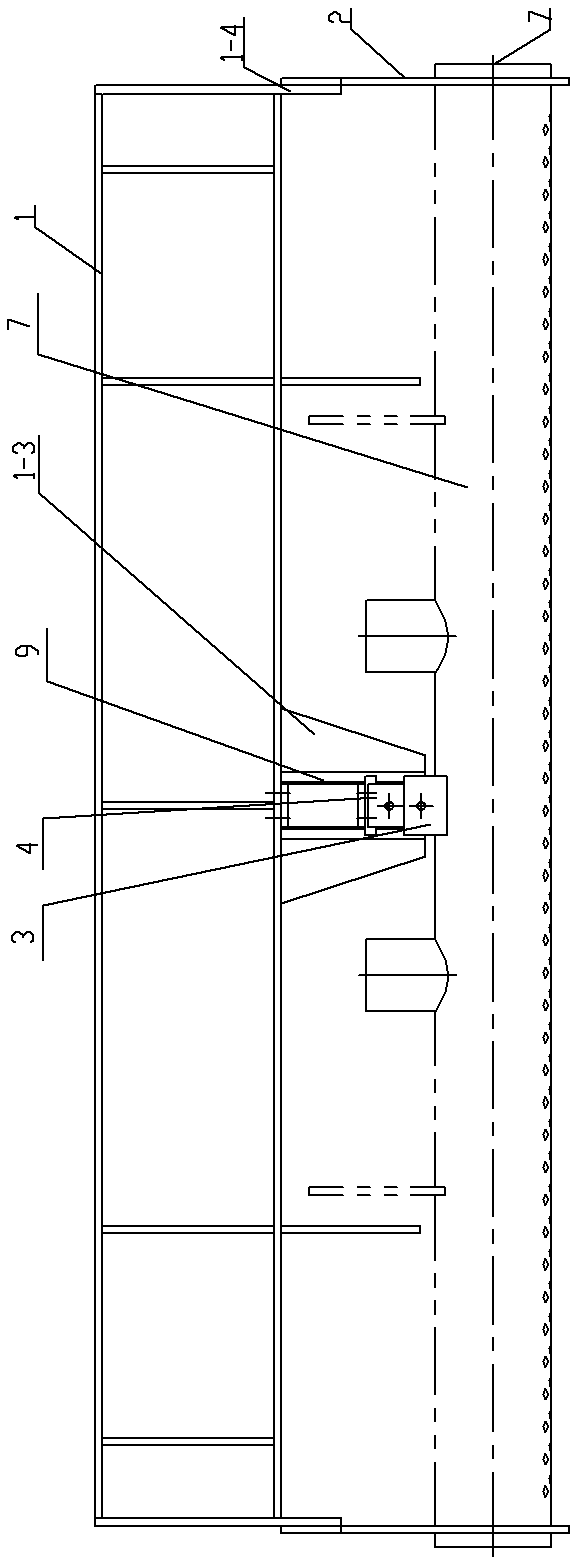

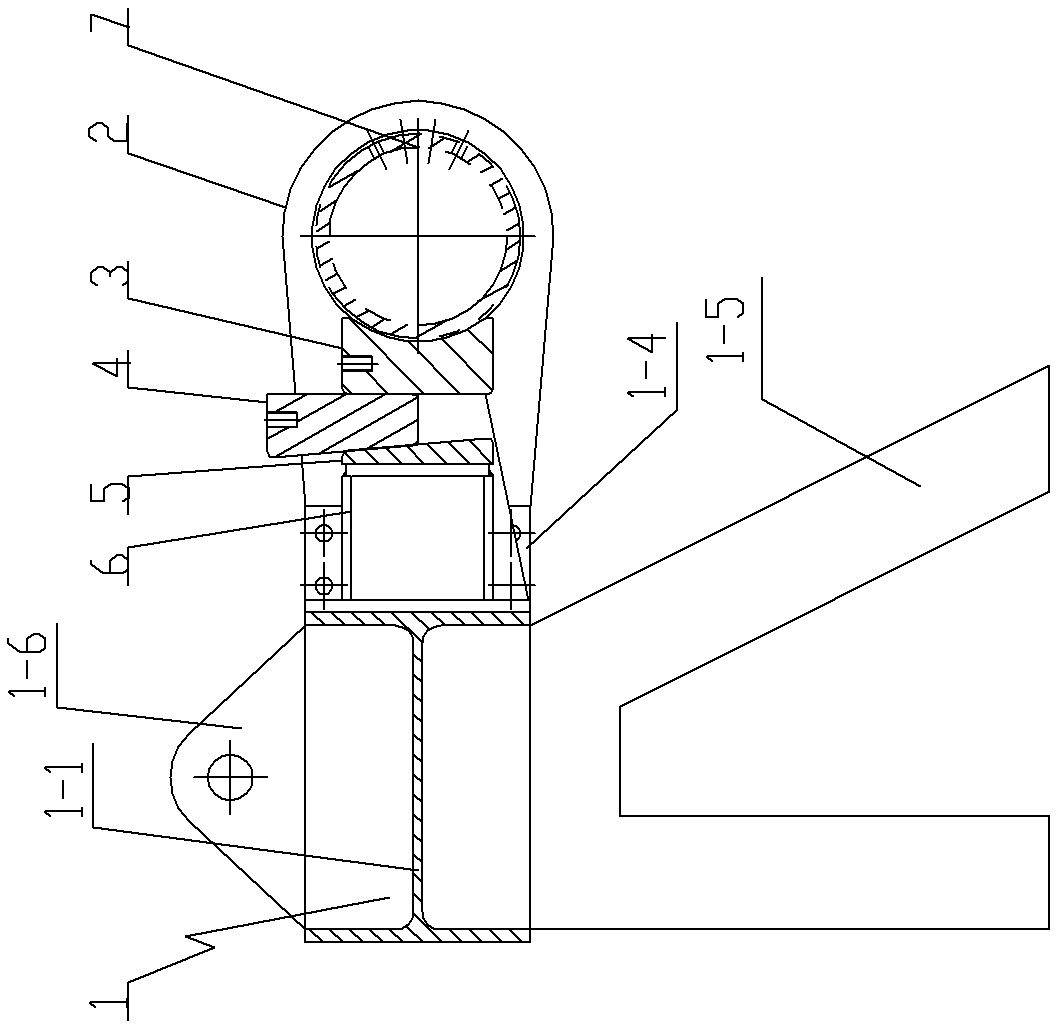

[0021] See Figure 1 to Figure 6 As shown, a multi-pipe joint header welding device, which includes a rigid main beam 1, the two ends of the rigid main beam 1 are respectively equipped with pull plates 2, the number and position of the pull plates 2 can be adjusted according to actual needs and welding positions. Adjustment, there is a header through hole 8 on the pull plate 2, and a guide rail 9 is fixedly installed on the rigid main beam 1. The guide rail 9 is arranged between the two pull plates 2. This position can also be adjusted according to actual needs. The guide rail 9 is formed by two vertical plates 1-2 arranged side by side at intervals, reinforcing plates 1-3 are installed on both sides of the guide rail 9, movable top-tightening sliders 3 are arranged on the guide rail 9, and one side of the top-tightening slider 3 is provided with The arc-shaped tight surface that matches the surface of the header 7 is used in conjunction with headers of similar size and specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com