a bending machine

A technology for bending machines and bending rods, applied in the field of bending machines, can solve the problems of being unable to produce U-shaped or Z-shaped photovoltaic ribbons and photovoltaic ribbons, so as to ensure bending efficiency, convenient use, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

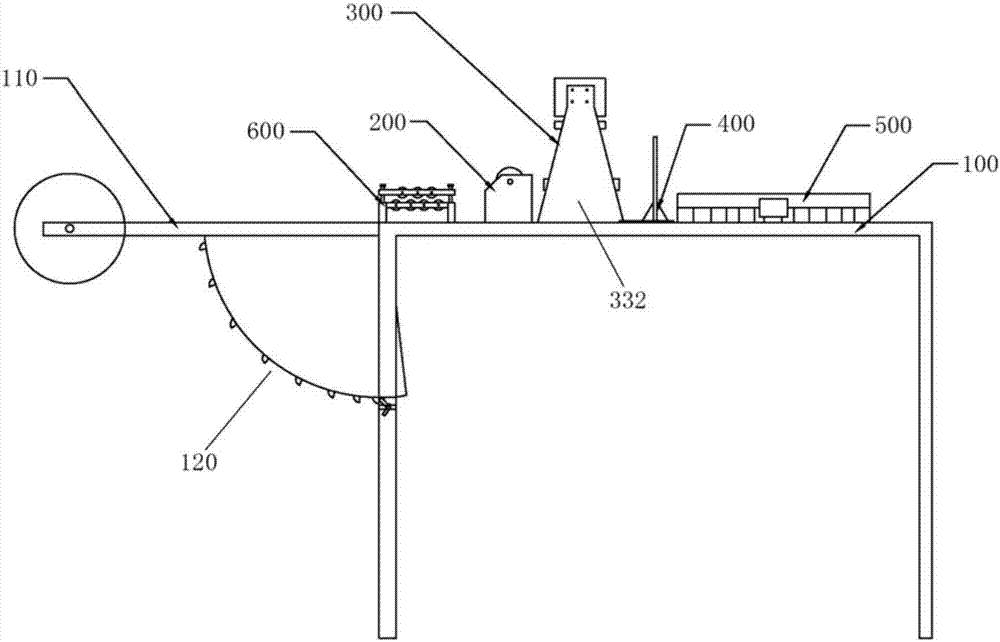

[0040] figure 1 It is a schematic diagram of a bending machine according to the present invention. like figure 1 As shown, the bending machine includes a workbench 100 and a feeding device 200 , a bending device 300 , a cutting device 400 and a pushing device 500 arranged sequentially on the workbench 100 along the ribbon conveying direction. Wherein, the workbench 100 further includes a recoverable material rack 110 and a caliper 120 for positioning the material rack 110 . When in use, the material rack 110 can be unfolded and positioned at a proper position by the caliper 120 ; when not in use, the material rack 110 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com