Floor nozzle for a vacuum cleaner

A technology for vacuum cleaners, floors, applied in the direction of vacuum cleaners, suction nozzles, applications, which can solve the problem of not always ensuring effective cleaning, increasing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

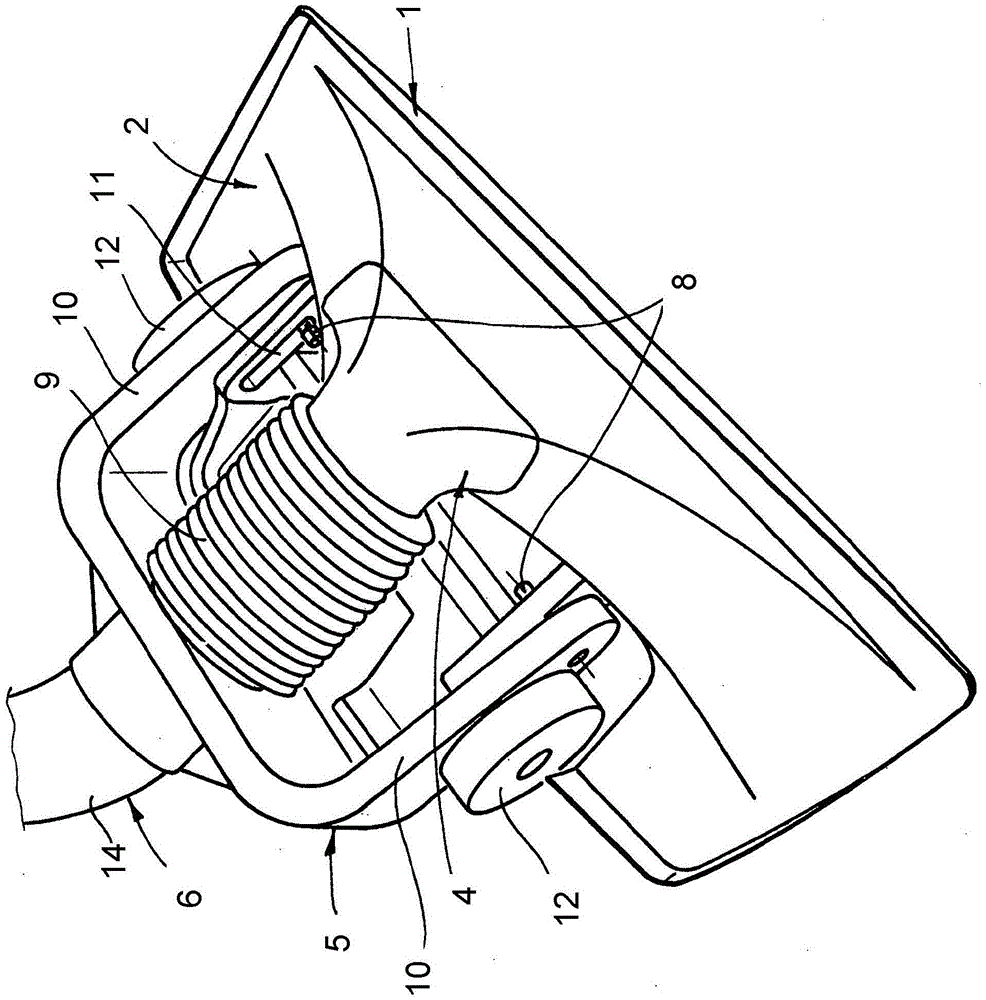

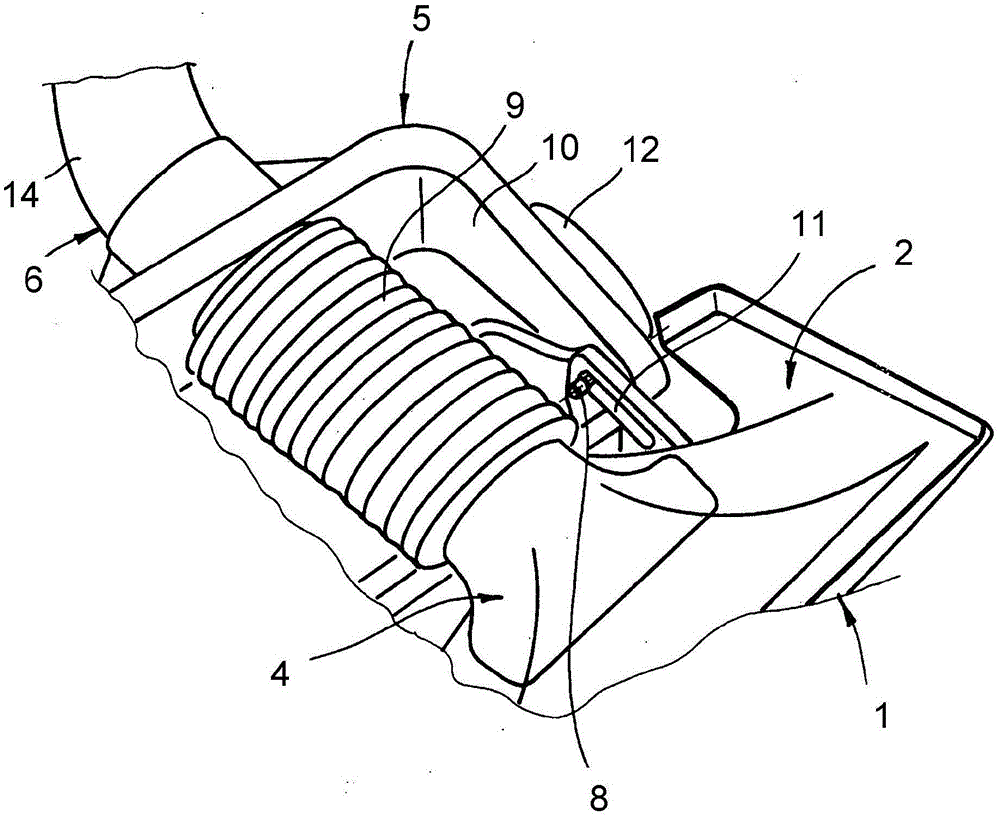

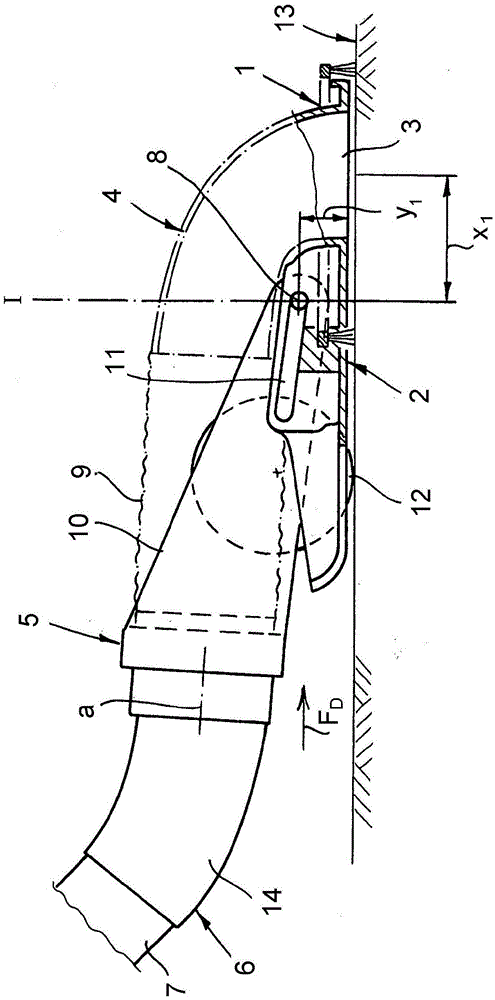

[0016] The figures show a so-called static floor nozzle for a vacuum cleaner that does not have any rotating cleaning tools. The floor nozzle comprises a nozzle body 1 with a bearing surface 2 at the bottom and a suction opening 3 and a suction channel 4 for discharging the flow of suction air flowing into the suction opening. Typically, the nozzle body 1 is also provided with a cover, but said cover is not essential to the function of the nozzle body and is therefore not shown in the drawings. The floor nozzle also comprises a support 5 having a connecting element 6 for the suction pipe 7 and connected to the nozzle body 1 so as to be pivotably movable about a pivot 8 . Provided between the suction tube connecting element 6 and the suction channel 4 are means for the fluid connection which compensate for the relative movement between the suction tube connecting element 6 and the suction channel 4 and for example Implemented as corrugated hose.

[0017] Compressive and tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com