Compensation device for uniformity of lighting pupil of photoetching machine and compensation method of compensation device

A technology of compensation device and lithography machine, which is applied in the direction of microlithography exposure equipment, photolithography exposure device, photomechanical equipment, etc., which can solve the problem of occupation and achieve the effect of saving space and reducing repeated installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

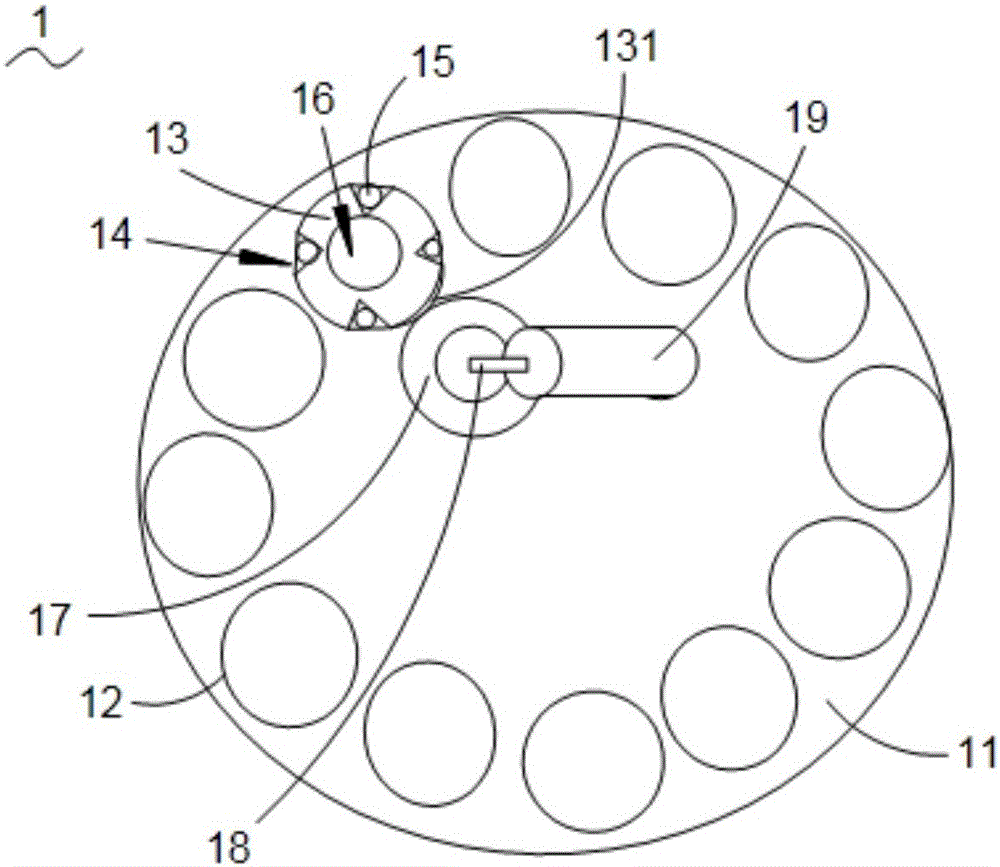

[0021] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0022] At present, in the field of semiconductor lithography, the uniformity of the illumination pupil of the lithography machine is compensated by the Auto Pupil Compensation Filter (AutoPCF), whose function is to adjust the four positions of the illumination pupil in the X and Y directions. uniformity of brightness.

[0023] As a person skilled in the art, it is not difficult to know that in the compensation process, the machine automatically selects the appropriate filter according to the size of the pupil light to adjust the I a , I b , I c , I d Specifically, according to the following formula of X, Y, XY to judge whether the pupil uniformity meets the requirements:

[0024] X={|I c -I d | / (I c +I d )}×100%

[0025] Y={|I ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com