A self-calibration circuit and self-calibration method

A self-calibration and circuit technology, applied in the direction of measuring electrical variables, instruments, measuring devices, etc., can solve the problems of high cost and low precision, and achieve self-calibration cost reduction, high precision, and reduction of analog-to-digital converters and digital compensation algorithms Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

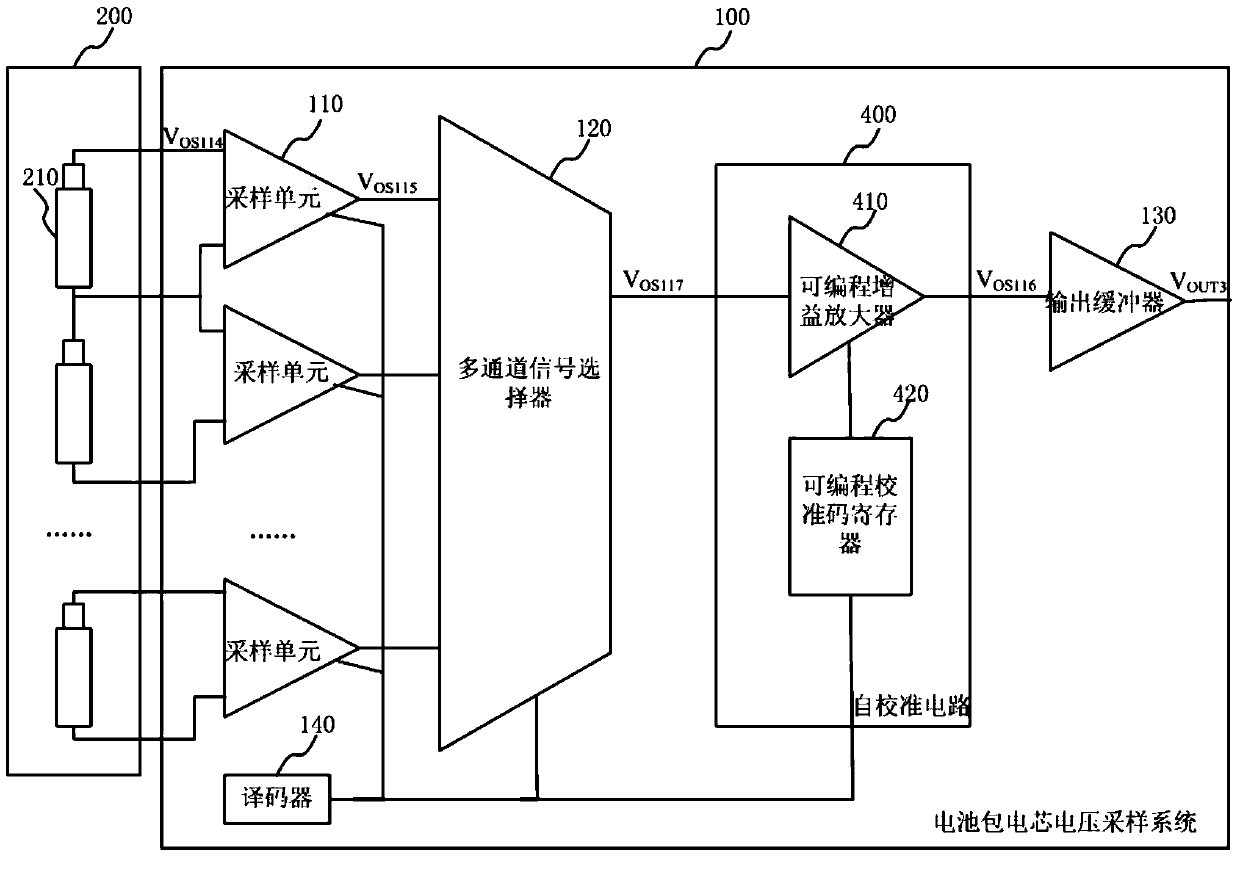

[0059] Such as image 3 As shown, the self-calibration circuit 400 of this embodiment includes a programmable gain amplifier 410 and a programmable calibration code register 420 . Among them, the programmable calibration code register 420 is used to store a plurality of calibration codes, and the calibration code is corresponding to each sampling unit 110 of the battery pack cell voltage sampling system 100, and its input terminal is connected to the battery pack cell voltage sampling system 100. The output terminal of the decoder 140 is connected to select the calibration code corresponding to the channel according to the channel gating signal output by the decoder 140 , and decode the calibration code to obtain the calibration code gating signal and output it to the programmable gain amplifier 410 . The input end of the programmable gain amplifier 410 is connected with the output end of the multi-channel signal selector 120 of the battery pack cell voltage sampling system, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com