Air valve noise suppression system and suppression method for rail transit oil-free air compressor

An oil-free air compressor, noise suppression technology, applied in the direction of mechanical equipment, machines/engines, liquid variable displacement machinery, etc., can solve the problems of unable to meet the noise requirements of rail transit vehicles, high noise, etc., to prevent spillage, Effect of reducing noise and reducing high-frequency spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

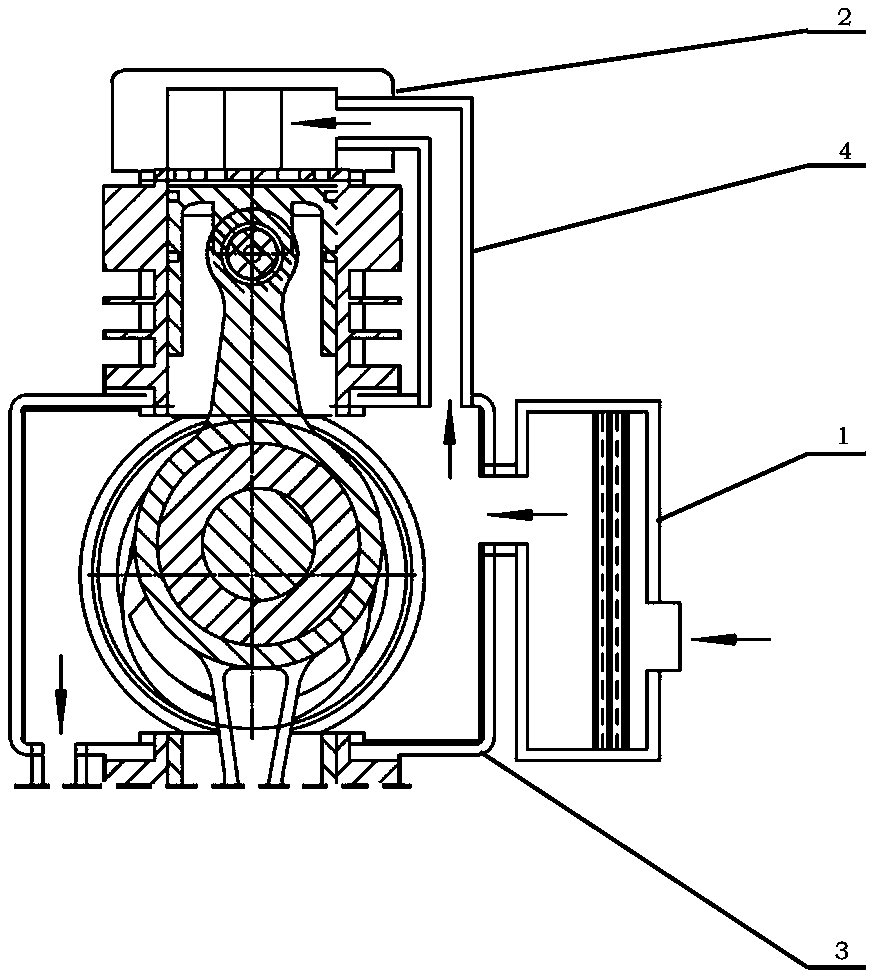

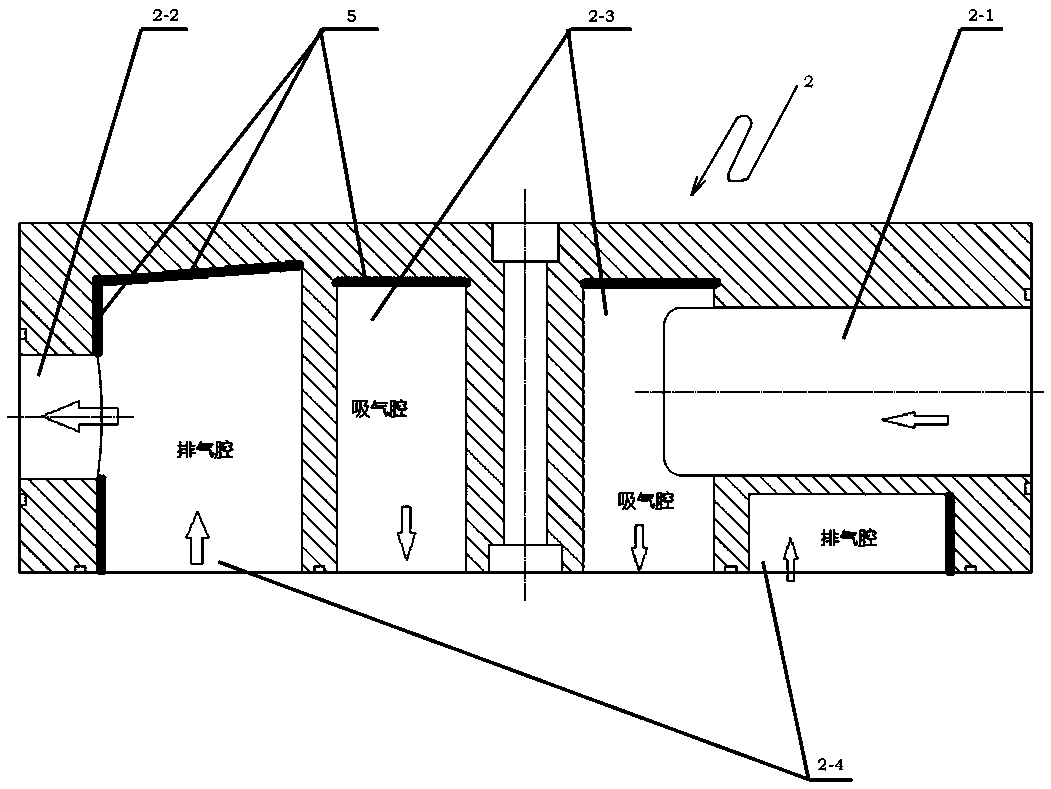

[0016] Such as figure 1 and figure 2 As shown, a valve noise suppression system for rail transit oil-free air compressors includes an air filter 1, a cylinder head 2, a crankcase 3 for accommodating a crankshaft, and an intake pipeline 4. In this embodiment, the air filter 1 is a plate-and-shell air filter, which includes a housing and a filter element arranged inside the housing. The filtering surface of the filter element is parallel to the plane on the corresponding side of the crankcase. The crankcase 3 communicates with the cylinder head 2 and the air filter 1 at the same time, the intake port of the crankcase 3 communicates with the exhaust port of the air filter 1, and the exhaust port of the crankcase 3 communicates with the cylinder head 2 through the intake pipeline 4 . The cylinder head 2 includes a cylinder air inlet 2-1, a cylinder exhaust port 2-2, an air suction chamber 2-3 and an exhaust chamber 2-4, and the cylinder air inlet 2-1 communicates with the air s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com