Leaf vegetable hydroponic nutrient solution and preparation method thereof

A hydroponic nutrient solution and mother solution technology, which is applied in agriculture, fertilization equipment, application, etc., can solve the problems of imbalance, high one-time investment in equipment, and yellow leaves, etc., and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

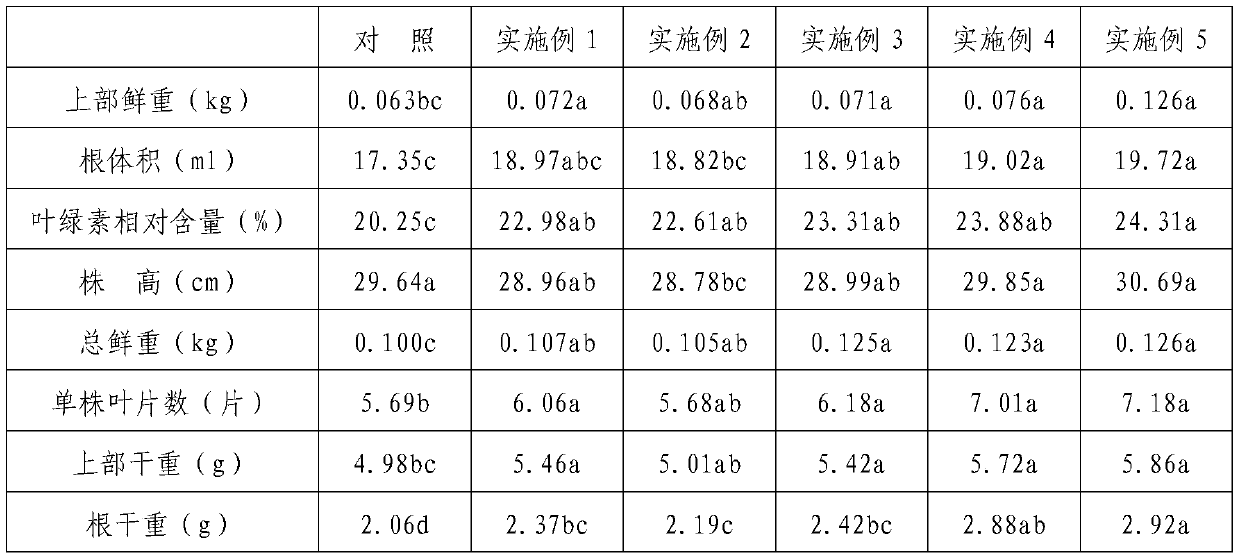

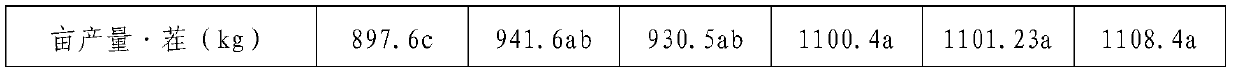

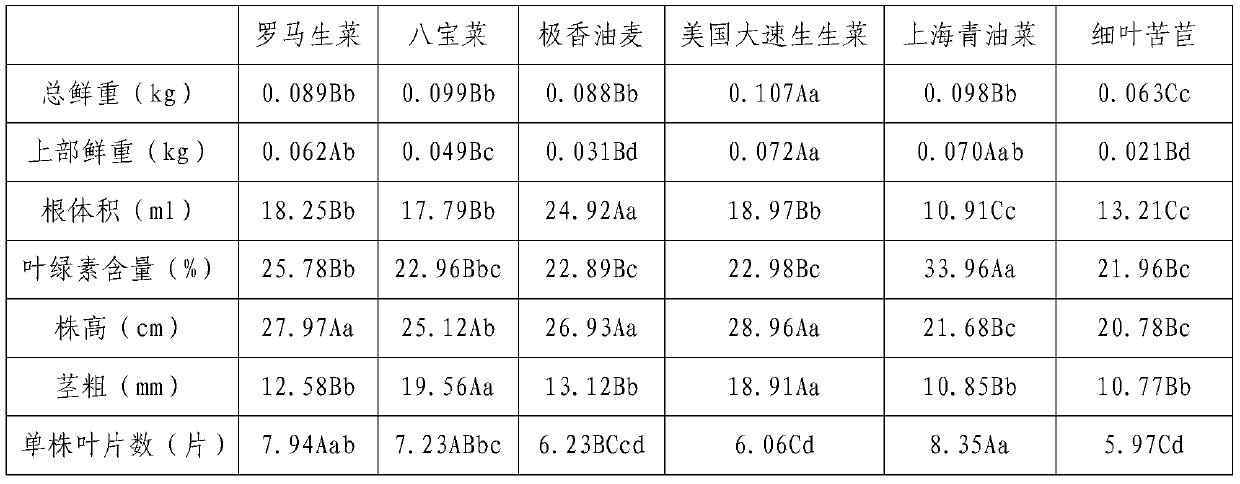

Examples

Embodiment 1

[0045] 1. Leaf vegetable hydroponic nutrient solution is composed of the following raw materials:

[0046] Ca(N0 3 ) 2 4H 2 O: 592mg / L; KH 2 PO 4 : 172mg / L; KNO 3 : 433mg / L; MgSO 4 ·7H 2 O: 860mg / L; Fe-EDTA: 21mg / L; NaNO 3 : 3.5mg / L; H 3 BO 3 : 3.2mg / L; Na 2 MoO 4 : 0.22mg / L; ZnSO 4 ·7H 2 O: 0.65mg / L; MnSO 4 4H 2 O: 2.2mg / L; NaCl: 0.82mg / L; the balance is water; pH=6.5, EC=1.5~3.0ds / m. .

[0047] The preparation method of leaf vegetable hydroponic nutrient solution comprises the following process steps:

[0048] A. Calcium nitrate and potassium nitrate are placed in the first liquid storage tank, mixed and dissolved, and water is added to constant volume according to the concentration ratio of the raw material content of the leaf vegetable hydroponic nutrient solution and stirred evenly to make the first mother liquor;

[0049] B. Put potassium dihydrogen phosphate, magnesium sulfate, chelated iron, sodium nitrate, boric acid, sodium molybdate, zinc sulfate, ...

Embodiment 2

[0060] Ca(N0 3 ) 2 4H 2 O: 590mg / L; KH 2 PO 4 : 170mg / L; KNO 3 : 430mg / L; MgSO 4 ·7H 2 O: 850mg / L; Fe-EDTA: 20mg / L; NaNO 3 : 3mg / L; H 3 BO 3 : 3mg / L; Na 2 MoO 4 : 0.2mg / L; ZnSO 4 ·7H 2 O: 0.6mg / L; MnSO 4 4H 2 O: 2mg / L; NaCl: 0.8mg / L; the balance is water; pH=6.8, EC=1.5~3.0ds / m.

[0061] The preparation method of the leaf vegetable nutrient solution in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0063] Ca(N0 3 ) 2 4H 2 O: 600mg / L; KH 2 PO 4 : 180mg / L; KNO 3 : 440mg / L; MgSO 4 ·7H 2 O: 900mg / L; Fe-EDTA: 25mg / L; NaNO 3 : 5mg / L; H 3 BO 3 : 4mg / L; Na 2 MoO 4 : 0.3mg / L; ZnSO 4 ·7H 2 O: 0.8mg / L; MnSO 4 4H 2 O: 3mg / L; NaCl: 0.9mg / L; the balance is water; pH=6.5, EC=1.5~3.0ds / m.

[0064] The preparation method of the leaf vegetable nutrient solution in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com