New conveying mechanism for soft bag or soft bottle

A conveying mechanism and soft bottle technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of easy deformation in contact, difficult accurate positioning and transportation, etc., achieve high-efficiency continuous work, reduce labor costs, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

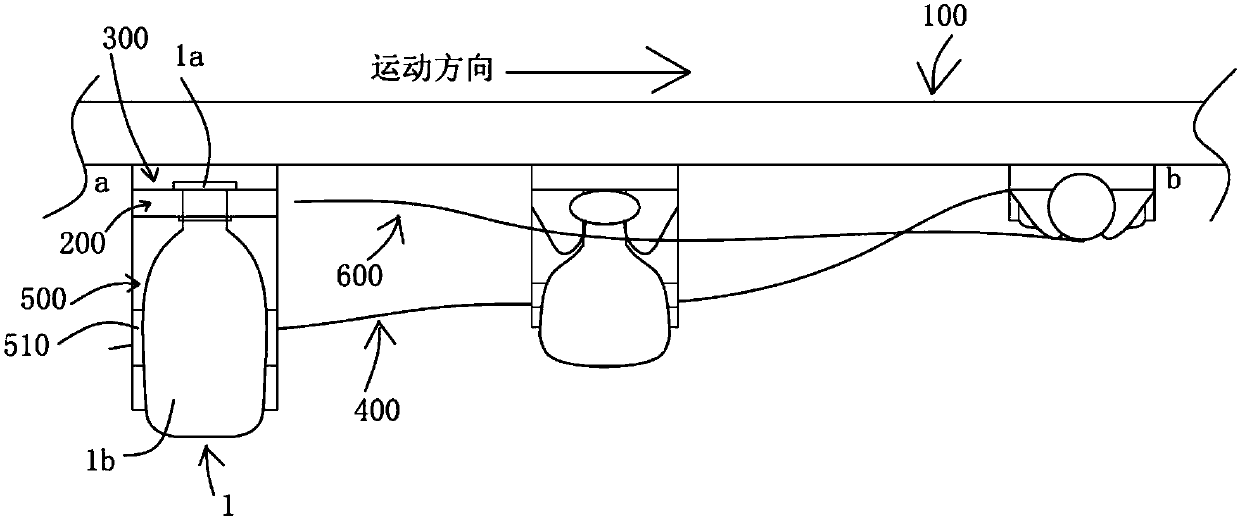

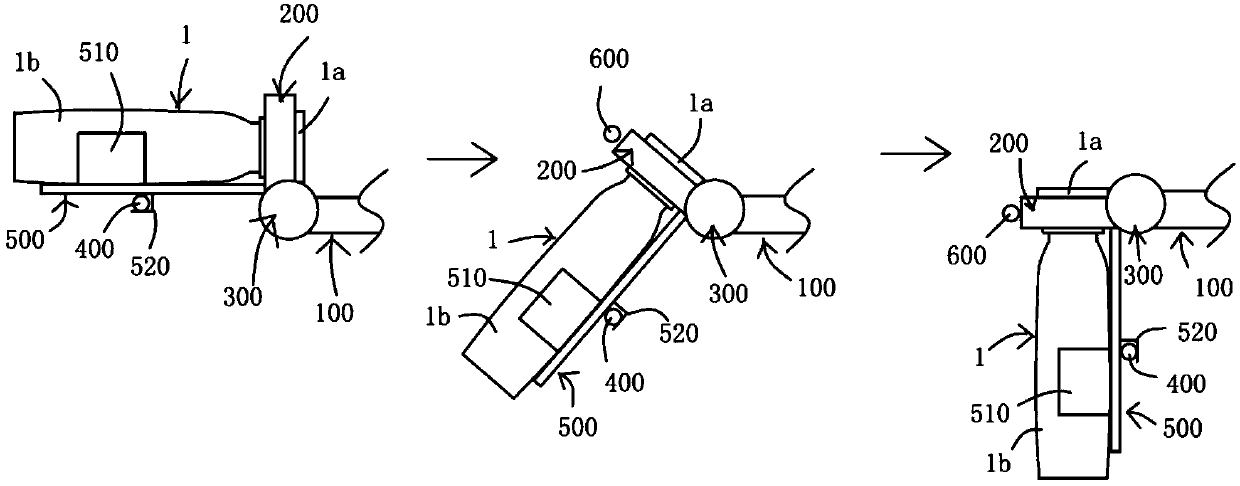

[0024] see figure 2 and image 3 The new soft bag or soft bottle delivery mechanism shown includes a moving device 100 and at least one clamping device 200 . The clamping device 200 is used to clamp the soft bag or soft bottle head 1a. The clamping device 200 is combined with the movement device 100 in a reversible connection. The clamping device 200 in this embodiment is a bayonet structure, which is convenient for the soft bag Or the soft bottle head 1a is stuck in the clamping device 200 . When the moving device 100 drives the clamping device 200 to move from the soft bag or soft bottle placement station a to the soft bag or soft bottle grasping station b, the degree of freedom of the soft bag or soft bottle 1 changes with the clamping device 200 And adjust the posture so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com