Paint bucket

A paint bucket and bucket body technology, applied in the field of paint buckets, can solve the problems of poor sealing of the paint cover, inconvenience to producers and users, etc.

Inactive Publication Date: 2016-07-06

CHANGZHOU ZHIYOU PAINT CO LTD

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the paint production process, the paint bucket is a common storage tool, but the traditional paint bucket only has a large cover. great inconvenience to users

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

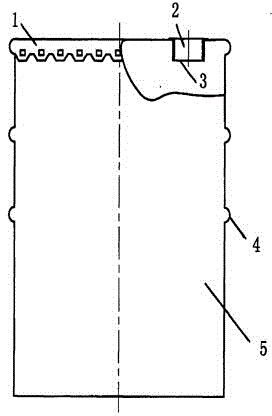

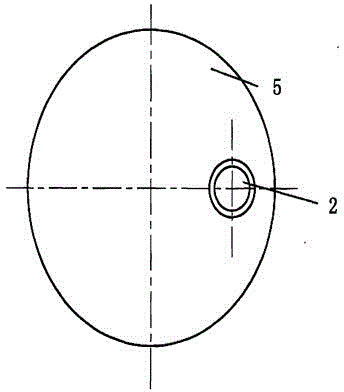

[0010] like figure 1 , 2 As shown, a plurality of outwardly protruding convex rings 4 are provided on the outer edge wall of the circular barrel body 5, and a circular barrel cover 1 with an arc-shaped edge is provided on the top of the circular barrel body 1. , a paint outlet 3 is provided on the round bung 1, and a small cover 2 is provided on the paint outlet 3.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a paint bucket. The paint bucket is characterized in that the peripheral wall of a circular bucket body is provided with a plurality of convex circular rings protruding outwards; a circular bucket cover with the circular-arc-shaped edge is arranged on the upper portion of the circular bucket body; the circular bucket cover is provided with a paint outlet; and a small cover is arranged on the paint outlet. Through the arrangement of the convex circular rings on the peripheral wall of the circular bucket body and the circular bucket cover with the circular-arc-shaped edge, the probability of deformation and damage to the paint bucket can be reduced. Through the arrangement of the paint outlet in the circular bucket cover, the quality of the paint which is not poured out of the bucket can be effectively maintained so as to facilitate use next time.

Description

technical field [0001] The invention relates to a paint bucket. Background technique [0002] In the paint production process, the paint bucket is a common storage tool, but the traditional paint bucket only has a large cover. The user brings great inconvenience. Contents of the invention [0003] The technical problem to be solved by the present invention is to provide a paint bucket with a paint outlet on the big cover of the paint bucket. [0004] In order to achieve the above object, the present invention is provided with a plurality of outwardly protruding convex rings on the outer edge wall of the circular barrel, and a circular bung with an arc-shaped edge is arranged on the upper part of the circular barrel. , a paint outlet is arranged on the round barrel cover, and a small cover is arranged on the paint outlet. [0005] Through the above settings, the convex ring and the arc-shaped circular bucket cover on the outer edge wall of the circular bucket body of the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65D47/06

Inventor 陈一鸣

Owner CHANGZHOU ZHIYOU PAINT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com