Driving technique for inner motor of switched reluctance drive (SRD) hub

An internal drive and wheel hub technology, applied in electric components, synchronous motors connected with control/drive circuits, used for single-phase current, etc., can solve problems such as complex structure, unsprung mass and large moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

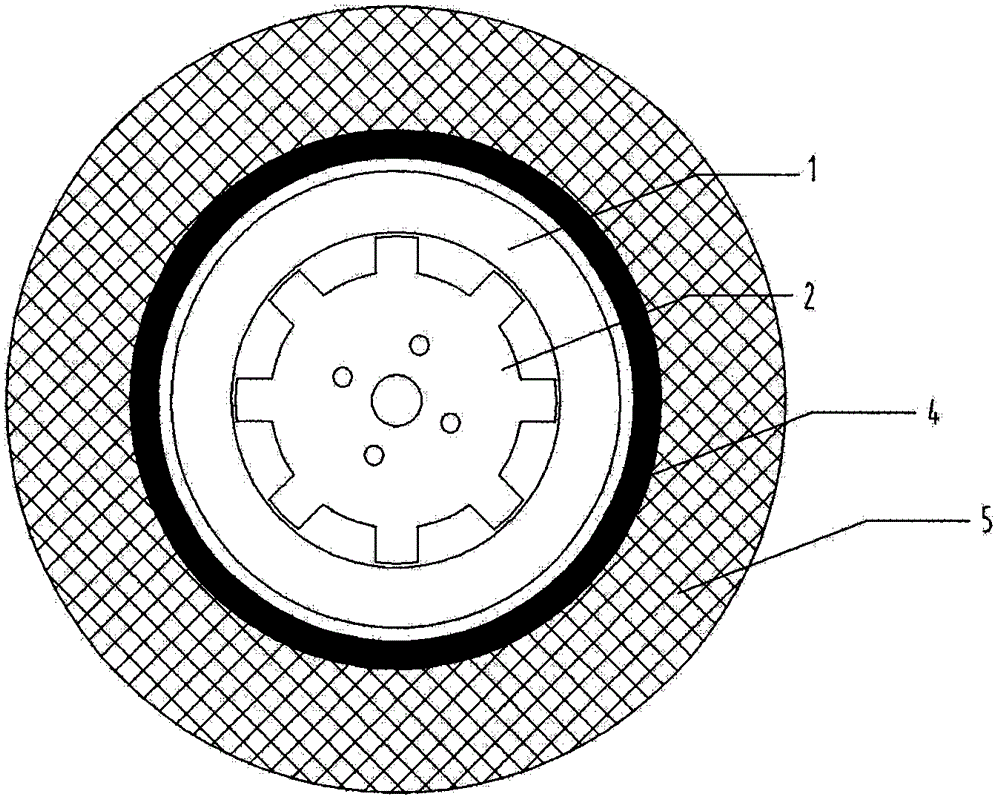

[0028] Example: such as figure 1 As shown, taking the structure of a 12 / 8 switched reluctance motor as an example, the driving part of the SRD drive device is composed of a stator 1 and a rotor 2. The stator 1 and the rotor 2 are made of silicon steel sheets with excitation functions and other materials. A coil 3 is provided. When the external speed controller controls the current on and off of the six pairs of salient pole coils 3 on the stator 1 according to the positions of the stator 1 and the rotor 2, the rotor 2 will rotate; Control, switch this driving device to the effect of slowing down the car (power generation state) or braking (reverse rotation). Such as figure 2 As shown, the driving device in the SRD hub is composed of a stator 1, a rotor 2, a hub 4 connected to the rotor and a tire 5. The stator 1 is fixed on the suspension of the locomotive and is located on the outer peripheral side or both sides of the rotor 2 . The rotor 2 is connected with the locomoti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com