Efficient garbage crushing equipment

A garbage crushing and equipment technology, applied in grain processing, etc., can solve problems such as poor production capacity, high operating consumption, high energy consumption in the crushing process, and achieve the effect of improving the working environment and realizing automatic compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

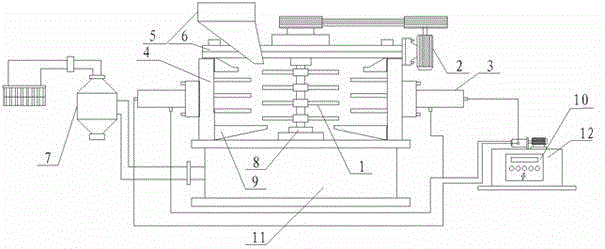

[0018] figure 1 The specific embodiment of the present invention is shown. As shown in the figure, a high-efficiency garbage crushing equipment of the present invention includes a body 6, a main shaft is installed in rotation in the body, and crushing blades 1 extending outward are evenly distributed on the circumferential surface of the main shaft. The outside of the main shaft is provided with a ring-shaped adjusting tooth plate 4, and the adjusting tooth plate is fixed on the body through the oil cylinder 3 to be telescopic to the center; the inner wall of the adjusting tooth plate 4 is evenly provided with crushing blades 1;

[0019] A feed hopper 5 is installed on the top of the body, and the materials to be processed enter the body from the feed hopper. The above-mentioned main shaft 8 rotates at a low speed under the action of the main motor 2, and the main motor is fixedly installed outside the body; the discharge space provided at the bottom of the body Cavity 11; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com