Treatment method for cracking and burning of industrial refuses and removal of tail gas and dust

A technology for tail gas dedusting and industrial waste, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

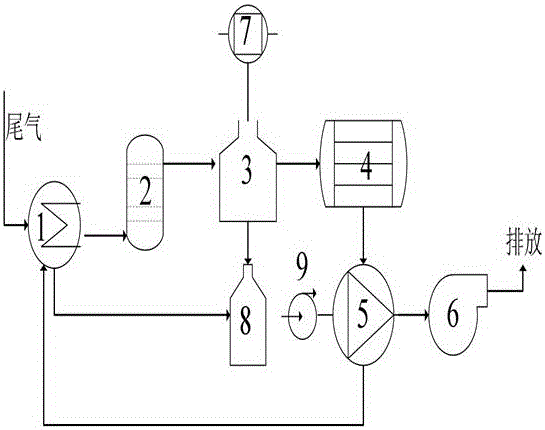

[0017] Such as figure 1 The shown industrial waste cracking and incineration tail gas treatment system includes tail gas cooling tower 1, multi-layer filter tower 2, multi-layer bag filter 3, bio-affinity dust removal tower 4, tail gas recirculation system 5, induced draft fan 6, air Compressor 7, dust collection tower 8, blower 9. The tail gas produced in the cracking waste incinerator is connected to the gas inlet of the tail gas cooling tower 1 through the pipeline, and the tail gas from the incinerator first enters the tail gas cooling tower 1, and the temperature of the tail gas is reduced to 50°C-80°C to meet the requirements of the subsequent bag dust removal . The cooling water in the tail gas cooling tower 1 is atomized by compressed air and then sprayed into the tail gas cooling tower 1 to directly contact the tail gas. The height of the tail gas cooling tower is set high enough to ensure that the sprayed atomized water can evaporate completely. While cooling down,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com