Electroosmosis high-voltage sludge elastic pressing filter plate, filter-press assembly and presser

A technology of electroosmosis and filter plate, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of sludge leakage, affecting filtration speed and efficiency, and insufficient feeding And other problems, to achieve the effect of high efficiency, improved filtration efficiency and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described:

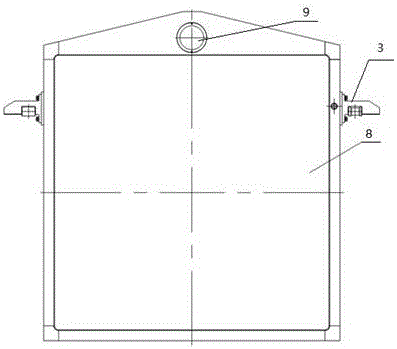

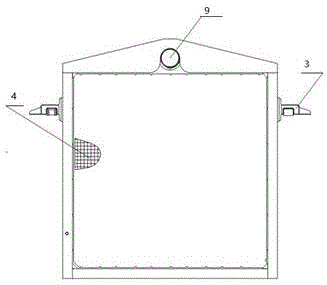

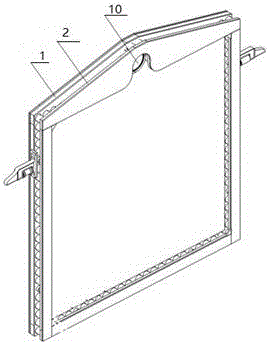

[0026] refer to figure 1 , figure 2 , image 3 , the present invention provides an elastic press filter plate and filter plate assembly for electroosmotic high-pressure sludge with upper feeding;

[0027] The elastic press filter plate uses the filter plate bottom plate 1 as the base plate, and the two sides of the filter plate are provided with filter plate handles 3; There are through holes (feed holes), filter frame 2 (such as image 3 ) as the elastic moving element of the filter chamber, supported by springs, and can be combined with the filter plate to form a hollow cavity (sludge filter chamber). A filter cloth with a special shape is laid in the hollow cavity of the filter chamber, and the filter frame Vulcanized rubber 6 with a certain thickness of 0.5-10mm on the outer surface.

[0028] The electroosmotic high pressure sludge elastic press filter plate of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com