Health-care composite shoe pad and production process thereof

A production process and technology of insole, applied in the field of insole, can solve the problem of incompatibility between the north and south regions, and achieve the effect of long service life and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

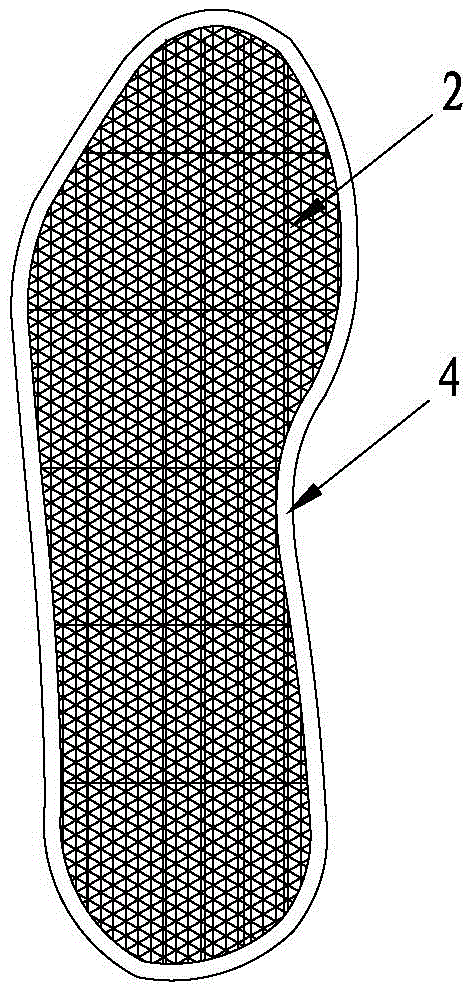

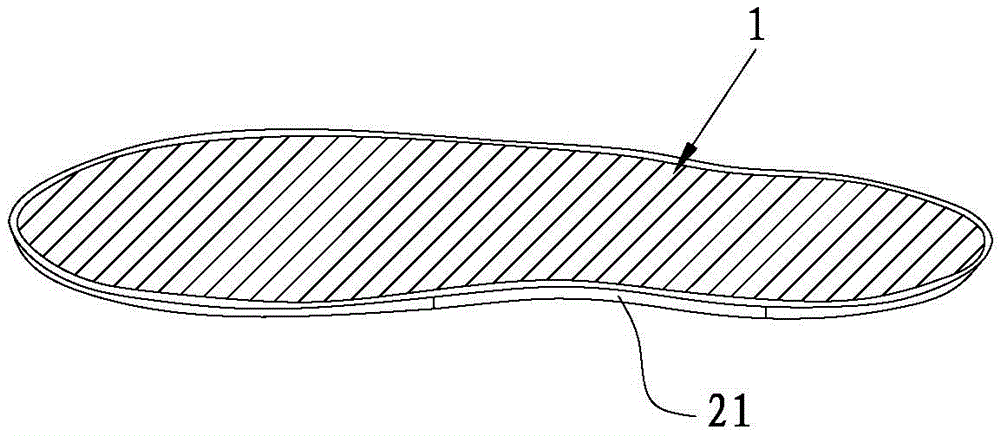

[0031] see Figure 1 to Figure 5 , a health-care composite insole, comprising an insole body, the insole body comprising a bamboo shoot leaf layer 1 and a hair palm layer 2 stacked, the edge of the bamboo shoot leaf layer 1 is fixedly connected to the edge of the hair palm layer 2 and a Assembling and disassembling the opening 21, the insole body also includes a medicine cushion layer 3, and the medicine cushion layer 3 is loaded between the bamboo shoot leaf layer 1 and the hair palm layer 2 from the disassembling opening 21. When using the health-care composite insole, users can use bamboo shoot leaf layer 1 or hair palm layer 2 as the top surface according to their own needs. According to "Compendium of Materia Medica" records, bamboo shoot leaves are soft in texture, moisture-proof, and have the function of deodorization ; Therefore, the bamboo shoot leaf layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com