Experiment method for testing permeability of rough fracture rock

A technique for permeability performance and fractured rock mass, applied in the fields of permeability/surface area analysis, measuring device, suspension and porous material analysis, etc. Inaccurate and other problems, to achieve the effect of convenient measurement, accurate and reliable measurement results, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

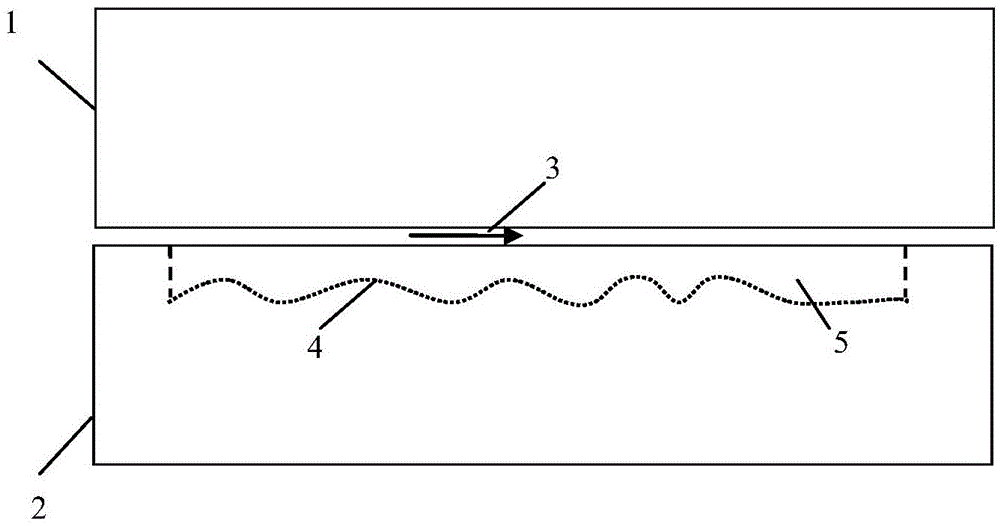

[0027] Such as figure 1 , figure 2 As shown, a kind of test method that is used for the permeability test of rough fractured rock mass in the present embodiment comprises the following steps:

[0028] Step 1. Device Layout

[0029] The rock mass to be tested is divided into upper and lower parts, and the upper rock mass 1 and the lower rock mass 2 are stacked up and down.

[0030] The upper rock mass 1 is provided with several through holes, some of which are water flow injection channels, and the rest of the through holes are water flow outflow channels.

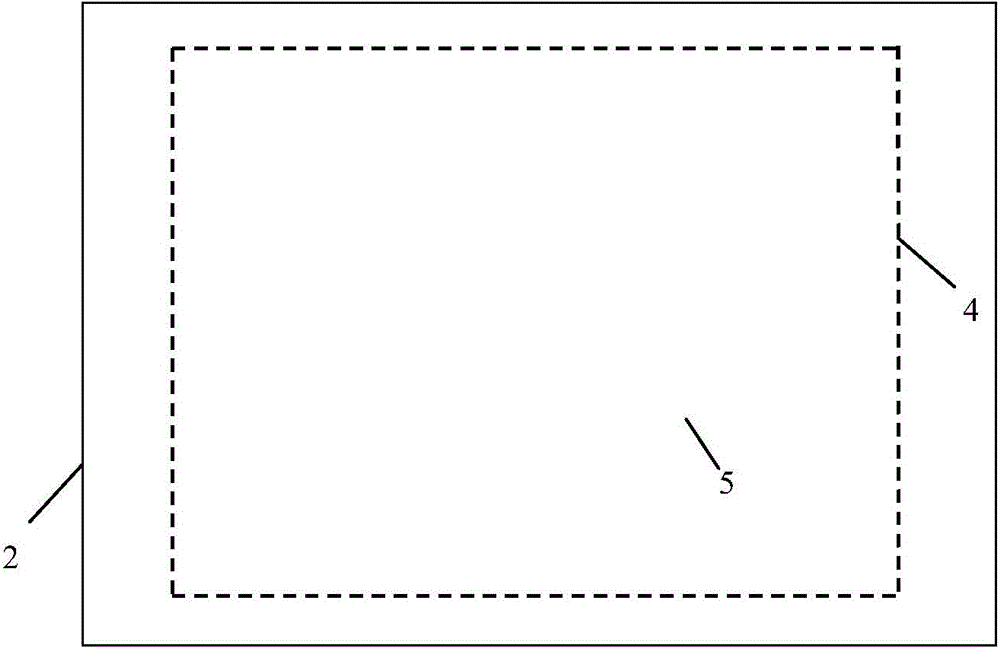

[0031] The upper surface of the lower rock mass 2 includes a contact area and a test concave area 5, the test concave area 5 is surrounded by the contact area, and the height of the test concave area 5 is lower than that of the contact area in the horizontal direction. The surface of the test concave area 5 is subjected to digging operations such as excavation and grooving to form a rock rough surface 4 with a certain r...

Embodiment 2

[0036] The difference between this embodiment and embodiment 1 is:

[0037] In step 2, a sealing device such as a sealing ring is provided on the lower surface of the upper rock mass 1 or the upper surface of the lower rock mass 2 to ensure that the water flow area 3 of the lower rock mass is inside the test concave area 5 .

Embodiment 3

[0039] The difference between this embodiment and the above two embodiments is:

[0040] In step 2, a water pressure control device is used to ensure that the water flowing through the lower rock mass area 3 is inside the test concave area 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com