Method for testing repeated positioning accuracy of machine

A technology of repeated positioning accuracy and testing method, applied in mechanical measuring devices, mechanical devices, measuring devices, etc., can solve the problem of repeated positioning accuracy not being able to measure and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention provides a test method for mechanical repeat positioning accuracy. In order to make the purpose, technical solution and effect of the present invention more clear and definite, the following examples are given to further describe the present invention in detail. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

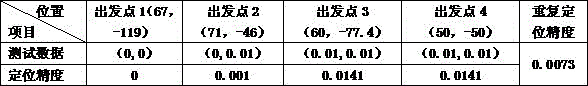

[0018] Mechanical repeat positioning accuracy test plan, using two dial gauges to measure in the visual positioning and closing gland robot station; the working area is 185x230mm2; the mechanical structure of the repeating motion includes the ball screw and the driven mechanical structure, every time it goes to Repeat the positioning position, use the striker to detect the mechanical structure at the positioning position, use the servo motor and servo driver, because the servo motor has no accumulated error during the walking process, so i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com