Optimal control system and method for variable-load economical operation of boiler

A technology of load optimization and economical operation, applied in the direction of control system, control of combustion, lighting and heating equipment, etc., can solve the problems of deviation from economic load area and high energy consumption of boilers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

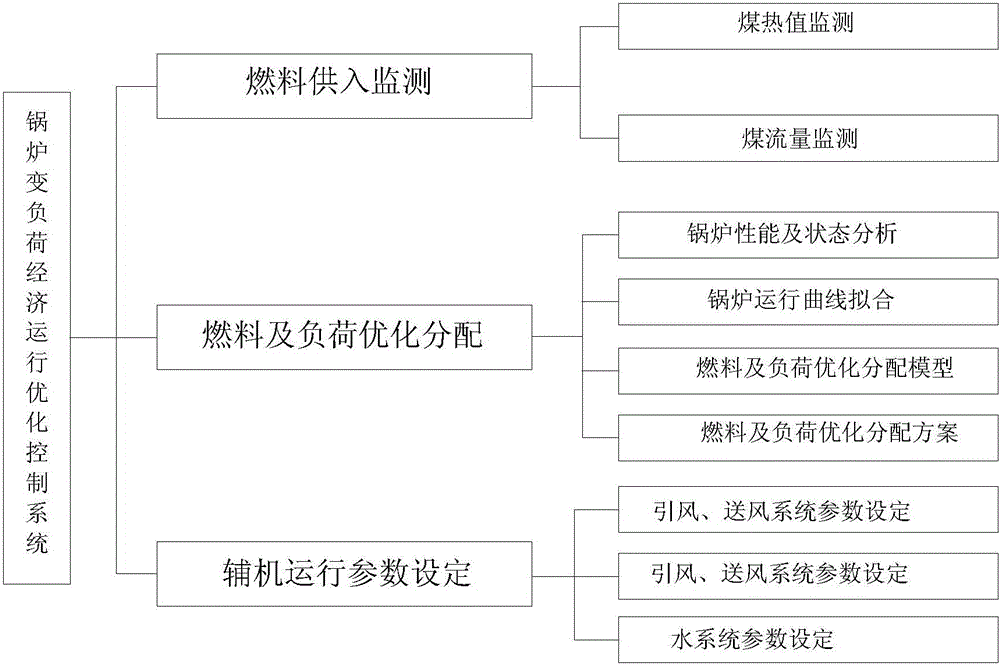

[0018] Aiming at the problem that the actual operation of the boiler deviates from the operation in the economical load area, resulting in high energy consumption, a boiler variable load economical operation optimization control system and method are proposed. The specific implementation methods are as follows:

[0019] Step 1: Monitor the supply of boiler fuel through the fuel supply monitoring subsystem, including the monitoring of coal calorific value and coal flow, and collect the monitoring data at the same time.

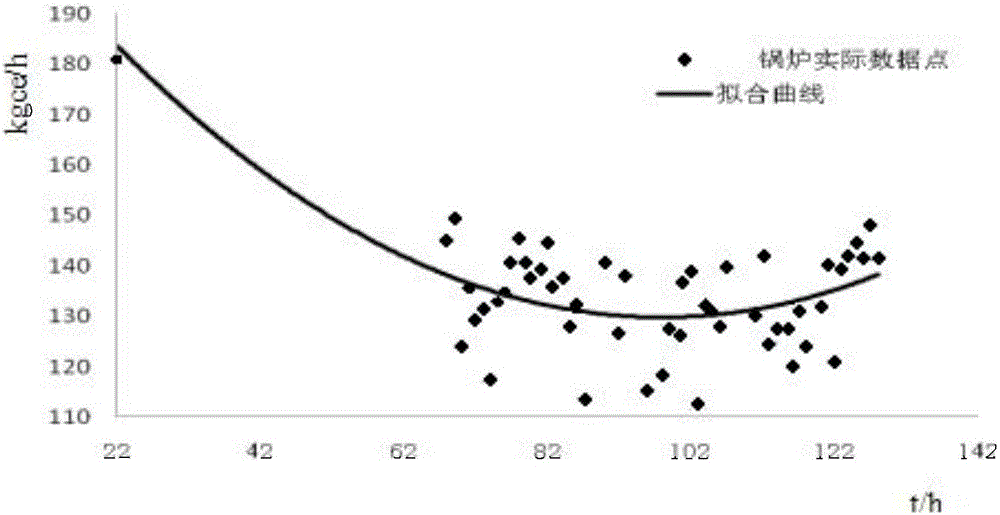

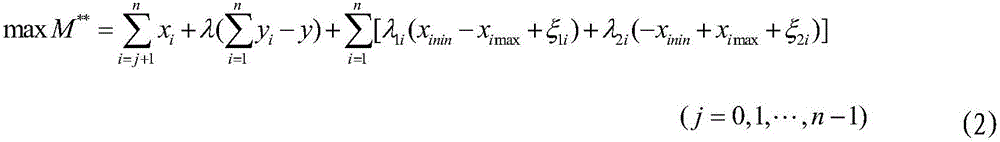

[0020] Step 2: Based on the data collected in step 1, process it through the fuel and load optimization distribution subsystem. First, analyze it through the boiler performance and state analysis module. Take a boiler with a rated load of 35t / h, a boiler thermal efficiency of 85%, and an economical Taking a boiler with an operating load of 101.9t / h as an example, the specific analysis process is as follows: data is collected through the fuel supply monitoring sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com