Slender-rod pressure release valve

A technology of slender rods and pressure relief valves, which is applied in the direction of safety valves, balance valves, valve devices, etc., can solve the problems of being unsuitable for high temperature and low pressure occasions, easy fatigue, and large changes in spring load, so as to shorten the maintenance cycle, Cost reduction, good orientation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

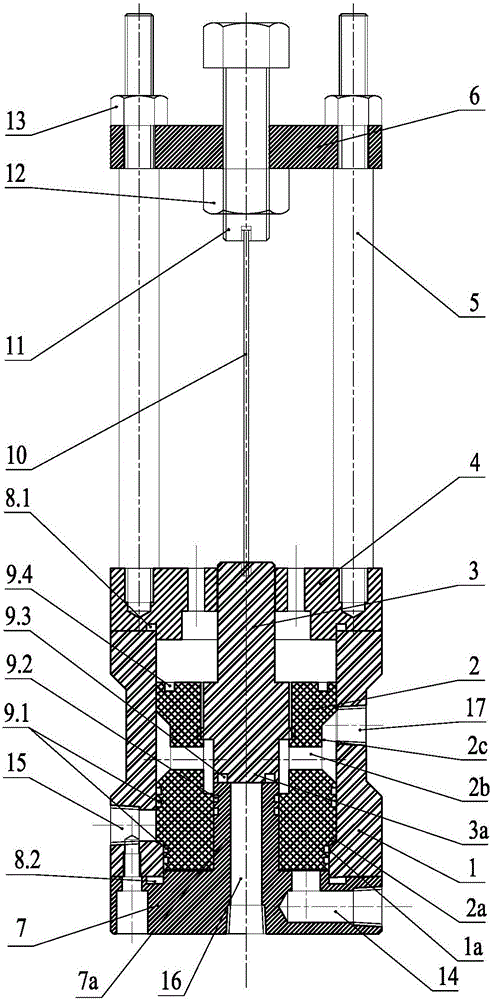

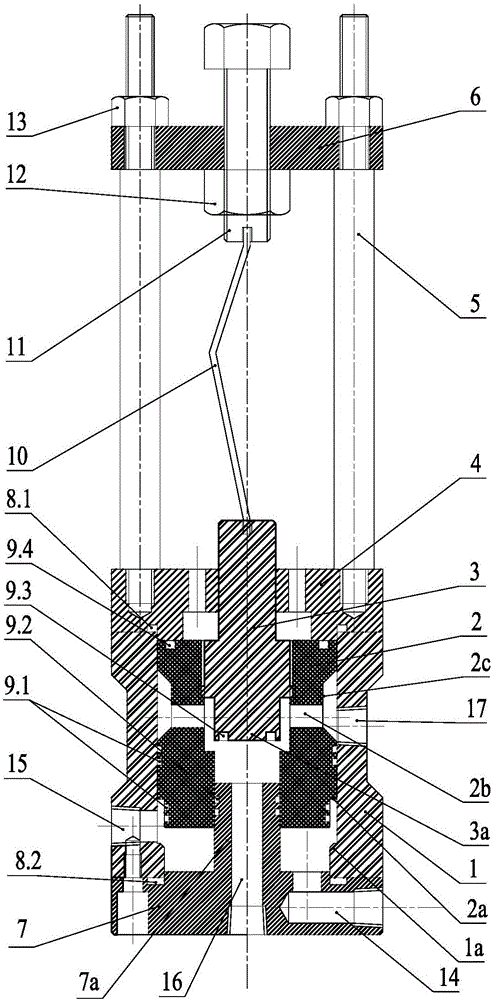

[0025] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0026] As shown in the figure: the slender rod pressure relief valve in the embodiment is mainly composed of a valve body 1, an upper valve cover 4, a bottom cover 7, a valve core 2, a valve rod 3 and a slender rod 10, etc., the valve body 1 It is a cylindrical body, the upper valve cover 4 is installed on the top of the valve body 1 by bolt sealing, and the bottom cover 7 is installed on the bottom of the valve body 1 by bolt sealing, and the upper valve cover 4, the valve body 1 and the bottom cover 7 form a A closed cylindrical cavity; the valve core 2 is assembled in the cylindrical cavity and can move up and down, the lower end of the valve stem 3 is connected to the valve core 2, and the upper end of the valve stem 3 passes through the central through hole of the upper valve cover 4 , the top of the stem 3 is connected to the lower end of a vertically arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com