A fully automatic water diversion device

A fully automatic, water-level technology, applied in driving pumps, machines/engines, non-variable-capacity pumps, etc., can solve the problems affecting the service life of vacuum pumps, vacuum pump suction effects, poor air and water separation effects, and complicated equipment installation and maintenance. problems, to achieve the effect of simple transportation, installation and maintenance, stable service life and efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In view of the deficiencies in the prior art, the inventor of this case was able to propose the technical solution of the present invention after long-term research and extensive practice. The technical solution, its implementation process and principle will be further explained as follows.

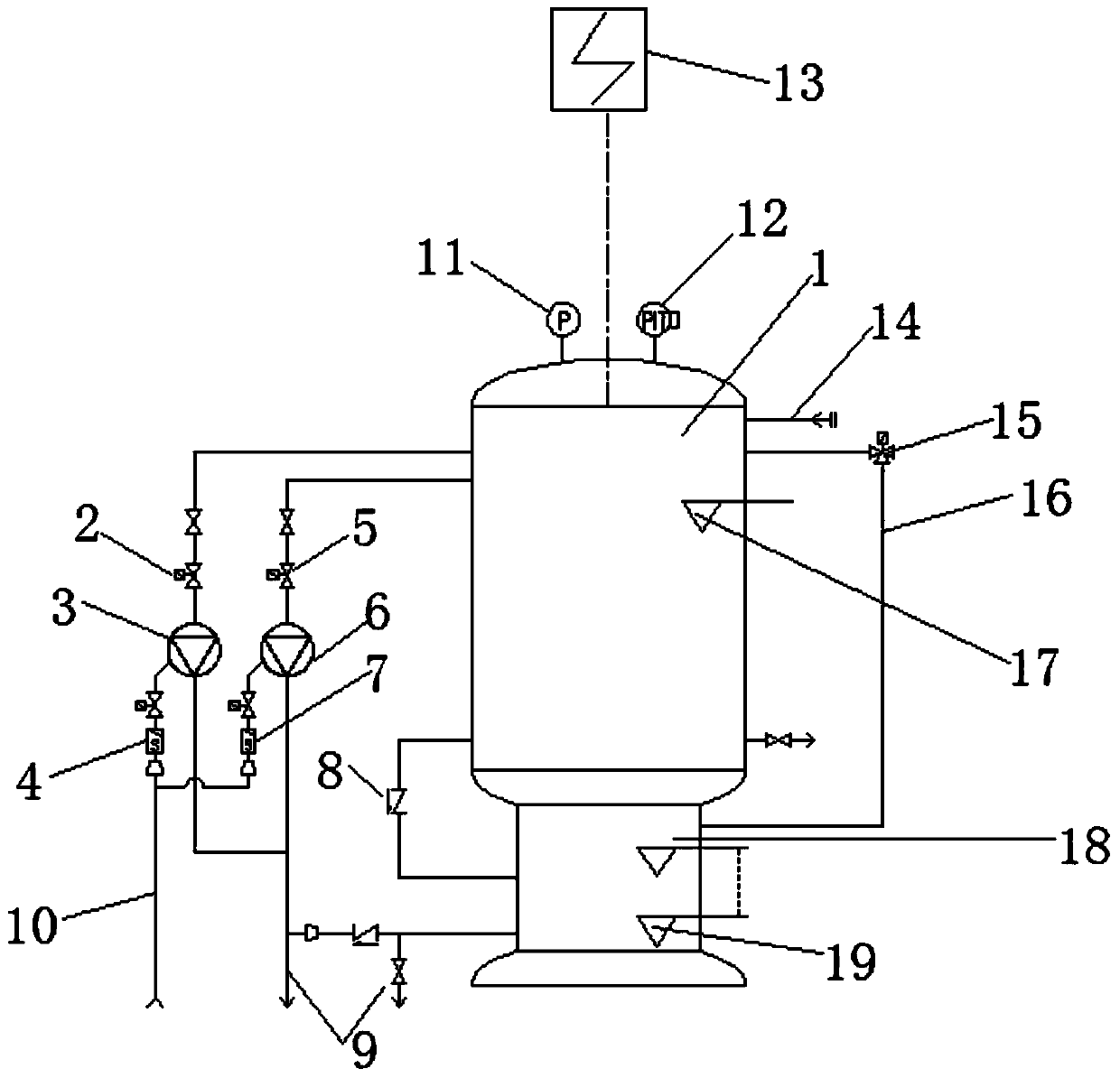

[0019] like figure 1 As shown, a fully automatic water diversion device includes a vacuum tank 1, an electric contact vacuum pressure gauge 12, a control cabinet 13, a first water level measuring instrument 17, a Unicom solenoid valve 15, a Unicom pipe 16, a water storage tank 18, a second Water level measuring instrument 19, first solenoid valve 2, first vacuum pump 3 and first fixed water level valve 4, the top of the vacuum tank 1 is connected with an electric contact vacuum pressure gauge 12, and the inside of the vacuum tank 1 is provided with a first water level measuring instrument 17 , the side wall of the vacuum tank 1 is provided with a suction main pipe 14 interface, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com