A kind of universal joint transmission device of submersible direct drive screw pump

A transmission device and universal joint technology, which is applied in the direction of pumps, drill pipes, pump components, etc., can solve the problems of large space occupation, high cost, and equipment efficiency of rod and tube eccentric wear, and achieve less floor space and lower maintenance costs , The effect of solving the problem of eccentric wear of the rod and tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

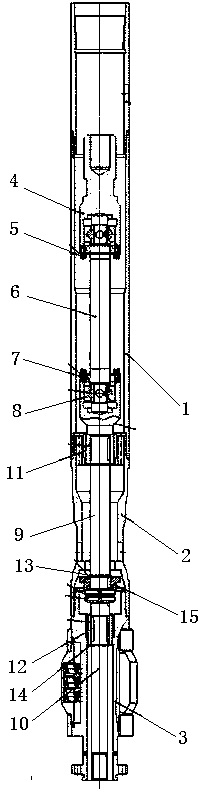

[0023] In order to overcome the common problems of eccentric wear of rods and pipes in directional wells, low equipment efficiency, large space occupation, and high cost, this embodiment provides a method such as figure 1 The shown submersible direct drive screw pump universal joint transmission device includes a screw pump, a transmission device and a motor connected in sequence from top to bottom, and is characterized in that the transmission device includes a long connecting pipe connected in sequence from top to bottom 1. Stator connecting pipe 2 and centralizer 3. The inside of the long connecting pipe 1 is sequentially connected with upper screw joint 4, universal joint 1 5, adjustment shaft 6, universal joint 2 7 and lower screw joint from top to bottom. 8, the stator connecting pipe 2 is provided with a connecting shaft 9 inside, the centralizer 3 is provided with a lower connecting pipe 10, the upper part of the long connecting pipe 1 is provided with a suction port, a...

Embodiment 2

[0029] In order to fasten the universal joint connection, on the basis of embodiment 1, this embodiment provides a method such as figure 1 As shown in the universal joint transmission device of the submersible direct drive screw pump, the universal joint 1 5 is fastened to the upper screw joint 4 through the spring washer with the inner hexagonal screw, and the universal joint 2 7 is fixed with the inner hexagonal screw through the spring washer. The hex screw is fastened to the lower threaded rod connector 8.

[0030] Further, the first universal joint 5 and the second universal joint 7 are provided with 8 universal adjustment blocks in the circumferential direction, and 8 steel balls are arranged inside the universal adjustment blocks.

[0031] Furthermore, the lower part of the universal joint 5 is provided with an oil seal, the upper part of the universal joint 7 is provided with an oil seal, and the oil seals are provided with an oil seal cover, and lubricating oil is ins...

Embodiment 3

[0033] On the basis of embodiment 2, this embodiment provides a kind of figure 1 In the shown universal joint transmission device of the submersible direct drive screw pump, the spline shaft 11 is provided with a wear-resistant sleeve inner sleeve outside, and the wear-resistant sleeve inner sleeve is provided with a wear-resistant sleeve outer sleeve, and the spline shaft 2 12 The exterior is provided with a wear-resistant sleeve inner sleeve, and the wear-resistant sleeve inner sleeve is externally provided with a wear-resistant sleeve outer cover. The lower screw connection head 8 rotates to drive the first spline shaft 11 to rotate, and the lower connecting pipe 10 rotates to drive the second spline shaft 12 to rotate, so that the first spline shaft 11 and the second spline shaft 12 wear more. The spline shaft one 11 is provided with a wear-resistant sleeve inner sleeve, the wear-resistant sleeve inner sleeve is provided with a wear-resistant sleeve outer sleeve, the splin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com