Rotary positioning device for console bracket

A positioning device and control room technology, applied in the direction of transportation and packaging, load hanging components, etc., to achieve high positioning stability, improve installation efficiency and installation safety factor, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

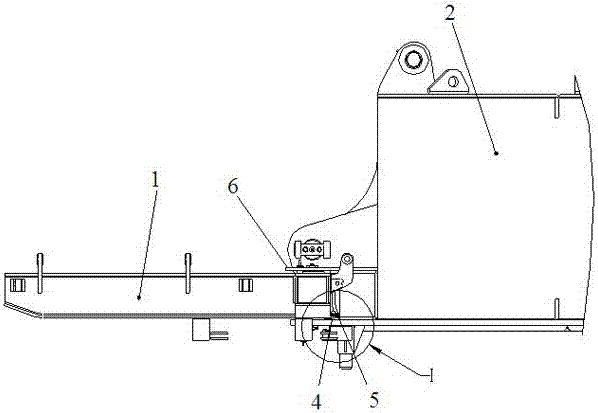

[0031] Such as Figure 2 to Figure 6 In the shown embodiment, the positioning plate 6 is arranged parallel to the upper surface of the control room bracket 1 , and the pin shaft 3 runs through the control room bracket 1 and the positioning plate 6 sequentially from bottom to top.

[0032] The positioning plate 6 is provided with 2 positioning holes 7, and the control room bracket 1 is provided with 1 positioning hole 7 adapted to the positioning holes 7 on the positioning plate 6, so that: when the control room bracket 1 is in the transport state 11 Or when the working state is 12, one of the positioning holes communicates with one of the positioning holes on the console bracket 1 on the positioning plate 6 .

[0033] The lower end of the nut plate 4 in the bolt positioning assembly is welded on the turntable 2; the head of the screw rod 5 faces the turntable 2, and the tail, ie, the end of the rod, faces the console 1 of the control room. The distance between the tail of the...

Embodiment 2

[0035] There are 2 positioning holes on the bracket of the control room, and 1 positioning hole on the positioning plate that is compatible with the positioning holes on the bracket of the control room, so that: when the bracket of the control room is in the transport state and working state, the positioning One positioning hole on the board communicates with two positioning holes on the console bracket respectively.

[0036] To sum up the above two embodiments, when the crane needs to be transported, the control room bracket is rotated to the transport state, so that the control room bracket is aligned with the positioning hole on the positioning plate, the positioning pin is inserted, and the bolt is tightened at the same time. The screw in the assembly makes the positioning of the cab bracket more secure. When it is necessary to assemble and then work, rotate the screw to leave a rotation gap for the control room bracket. After the control room bracket is rotated to the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com