A method for manufacturing a non-metallic anti-corrosion lighting board made of pre-woven parts with a flow-guiding layer

A manufacturing method and technology for pre-woven parts, which are applied in the manufacturing field of non-metal anti-corrosion lighting panels, can solve the problems of aging, nail hole wear, flame retardant performance, weather resistance and limited application, and achieve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the novel structure reinforced non-metallic anti-corrosion board daylighting board disclosed by the invention comprises the following steps:

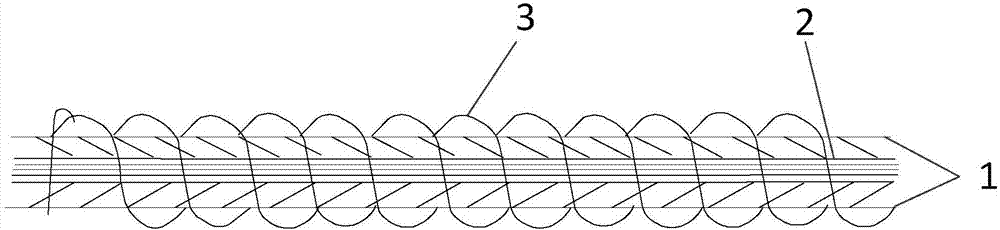

[0023] Step 1 Fabrication of Fiberglass Prewoven Parts

[0024] First lay the glass fiber mat 1 in layers, then add the diversion layer fiber cloth 2 to the middle layer position of the laid glass fiber mat 2, and then use the sewing technology to lay the layer through the high-strength continuous carbon fiber filament 3 The glass fiber mat 1 and the fiber cloth 2 of the flow-guiding layer are sewn together to obtain the glass fiber mat pre-woven part reinforced by carbon fiber interlayers.

[0025] The fiber cloth of the diversion layer can be made of polyolefin fiber unidirectional cloth, such as polypropylene fiber unidirectional cloth and polyethylene fiber unidirectional cloth. This fiber has a rod-like structure with a smooth surface, light weight, high strength, and good wear resistance. Polyprop...

Embodiment 1

[0035] Lay four layers of glass fiber mats 1, and then apply stitching technology to lay the diversion layer fiber cloth 2 between the second layer of glass fiber mats and the third layer of glass fiber mats, and then use high-strength continuous carbon fiber filaments 3 to The glass fiber mat 1 and the flow guide layer fiber cloth 2 are stitched together at a stitching density of 1 root / square centimeter, so as to obtain a glass fiber mat pre-woven piece reinforced between continuous carbon fiber layers.

[0036] Dissolve the interface coupling agent KH550 (5kg) in 1000L of ethanol, and then dissolve the aluminum hydroxide flame retardant (500kg) in the interface coupling agent solution. After stirring evenly, the ethanol solvent is distilled off to obtain a surface-treated aluminum hydroxide flame retardant.

[0037] Add 200kg of surface-treated aluminum hydroxide flame retardant, 1kg of ultraviolet absorber, and 20kg of pigment paste to 500kg of unsaturated resin, and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com