Crane boom segment for assembly of a crane boom, method for assembling a crane boom

A technology of cranes and booms, applied in the direction of cranes, etc., can solve problems such as lifting, errors, and large time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

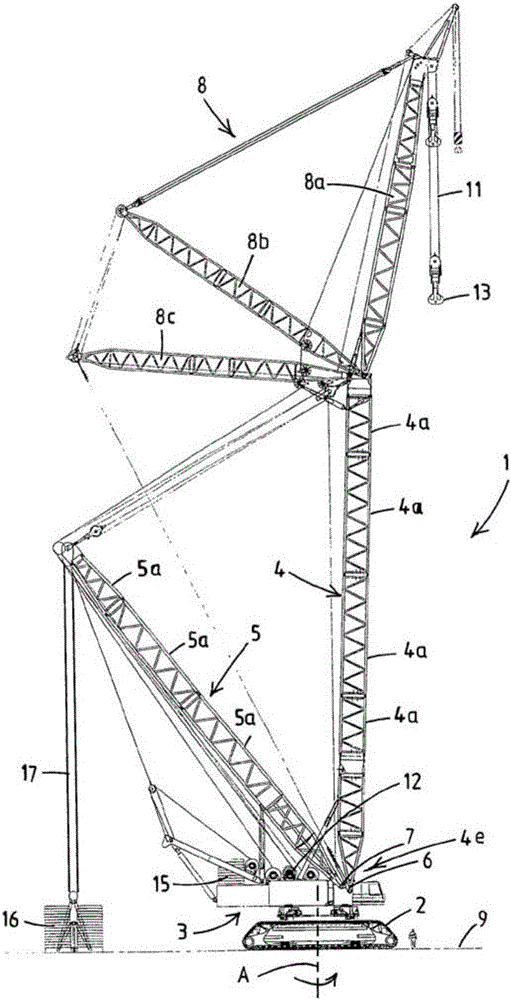

[0083] exist figure 1 A crawler crane 1 is shown, which is designed to lift loads of several hundred metric tons. The crane 1 shown is a self-propelled crane and has a mobile base structure 2 which enables the crane to move along a surface 9 . In many cases the surface is the ground possibly reinforced by suitable foundations, but the use of the crane on large pontoon bridges and the like is also envisaged.

[0084] A rotating superstructure 3 is mounted on the base structure 2 so that the superstructure 3 can rotate relative to the base structure 2 about a vertical axis of rotation A.

[0085] The crane 1 further has a boom 4 and a stern mast 5 . One end 4e of the boom is hinged to the superstructure 3 so as to pivot the boom 4 about a horizontal pivot axis 6 . The stern mast 5 is also hinged to the superstructure 3 about a horizontal pivot axis 7 . Furthermore, a fly jib arrangement 8 is provided which comprises an arm 8a and brackets 8b, 8c, both of which are pivotally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com