Gear with oil distribution tank, electric machine and vehicle

A technology of oil distribution grooves and gears, which is applied to mechanical equipment, components with teeth, gear lubrication/cooling, etc., can solve the problems of not considering the distribution of lubricating oil, reducing the effect of lubricating oil coating, and failing to distribute lubricating oil, etc., to achieve Long service life, reduced gear wear, and improved gear life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

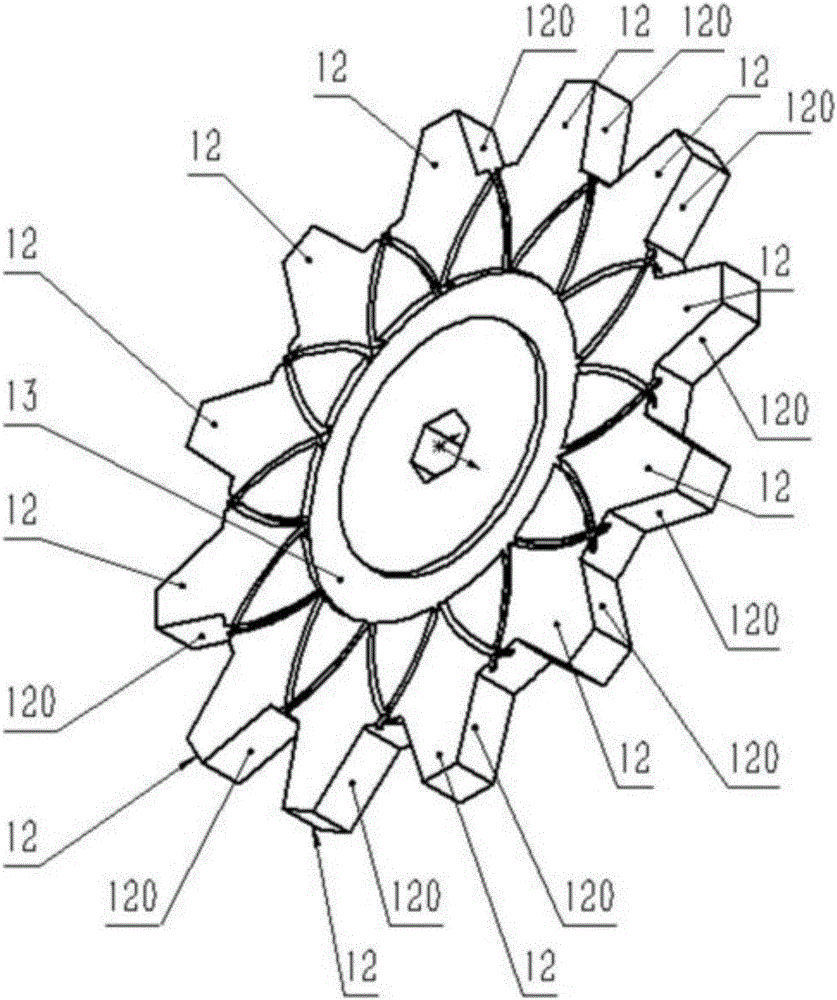

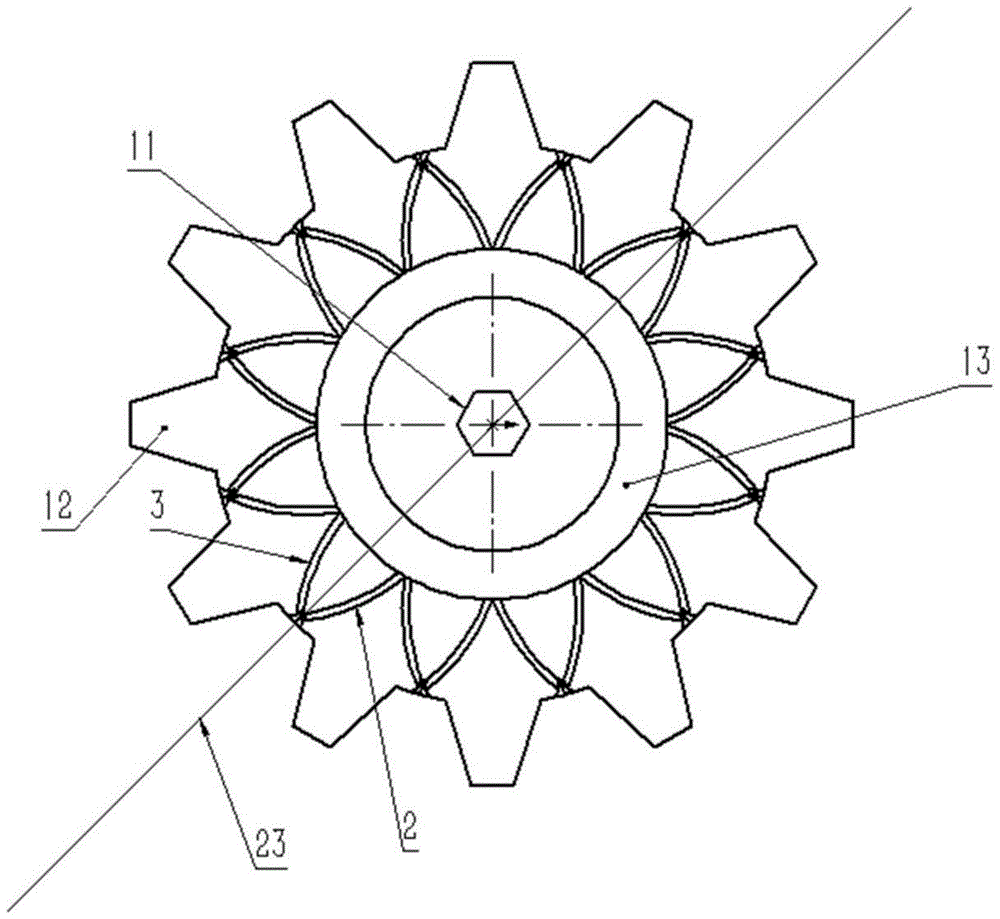

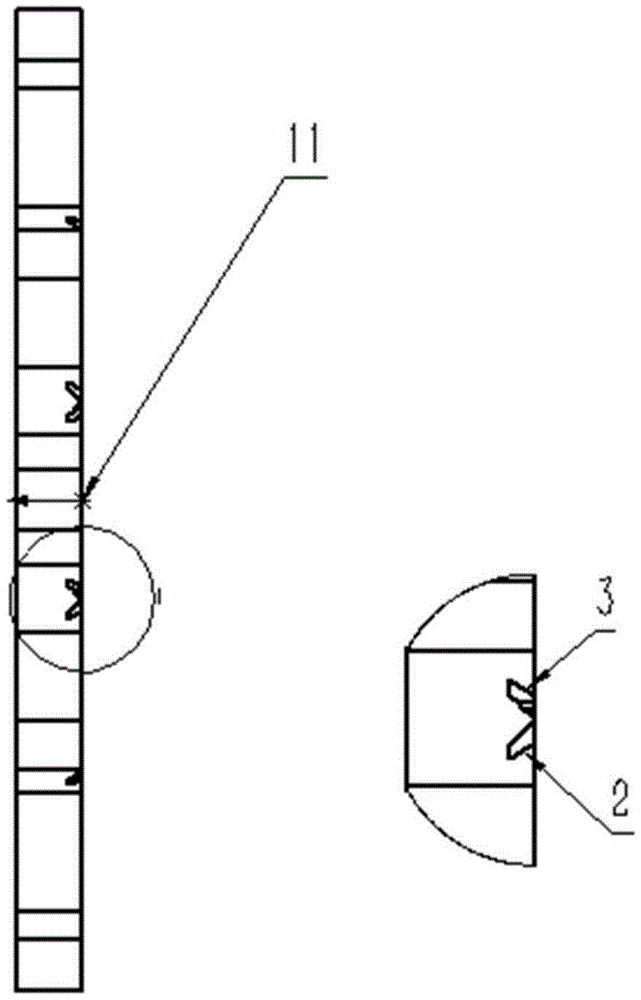

[0028] Implementation example 1, such as Figure 1-3 As shown, the gear with an oil distribution groove includes a main body 1, teeth 12, and a connecting portion 11, and is characterized in that it also includes a first curved groove 2, a second curved groove 3, and a connecting groove 13;

[0029] The clock directions of the tracks formed by the first curved groove 2 and the second curved groove 3 from the inner end to the outer end are different;

[0030] The first curved groove 2 and the second curved groove 3 are distributed in pairs on both sides of the connecting line 23 between the center of the tooth valley of the main body 1 and the axis of the main body 1;

[0031] The outer sides of the paired first curved groove 2 and the second curved groove 3 have openings at the tooth valleys of the main body 1. The function of this design is to allow the liquid in the grooves to flow out from the tooth valleys during the gear rotation. , and then splash on the contact transmi...

Embodiment 2

[0035] Implementation example 2, a gear, on the basis of implementation example 1, both planes have curved grooves.

Embodiment 3

[0036] Implementation example 3, an electric machine, has the gear described in implementation example 1, and the position is fixed during work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com