Device for treating low-concentration and difficult-to-degrade organic industrial wastewater

A technology for industrial wastewater that is difficult to degrade, applied in filtration treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of high operating cost and low treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

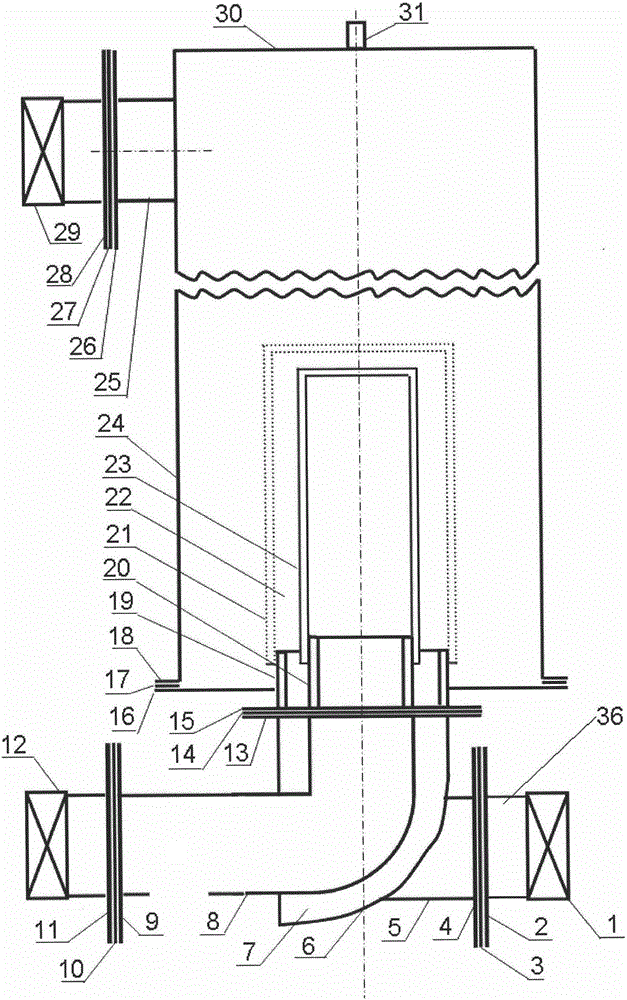

[0071] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

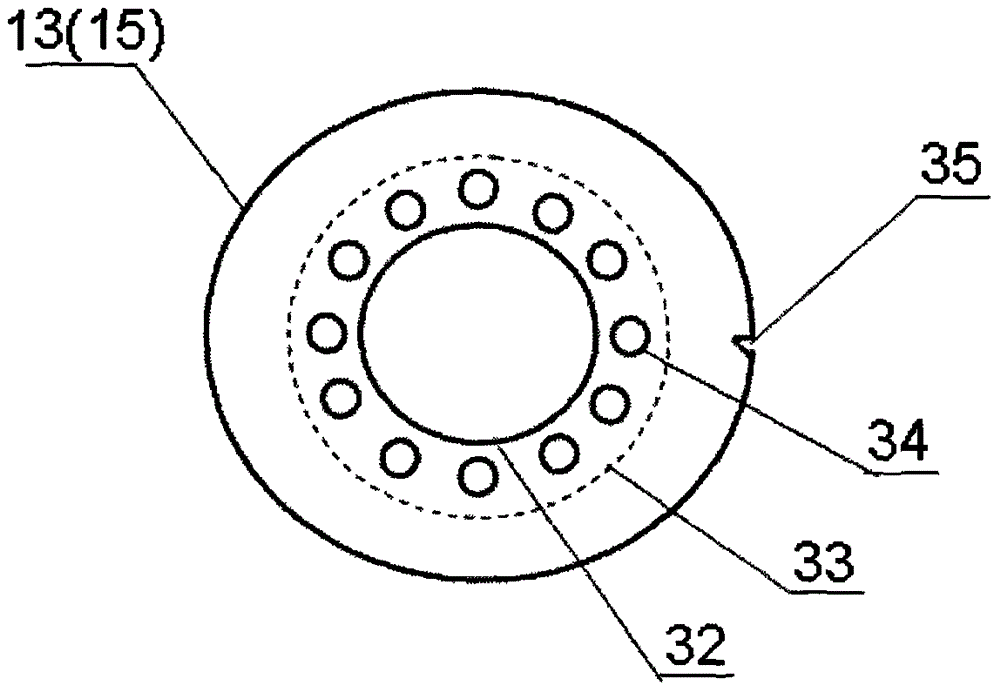

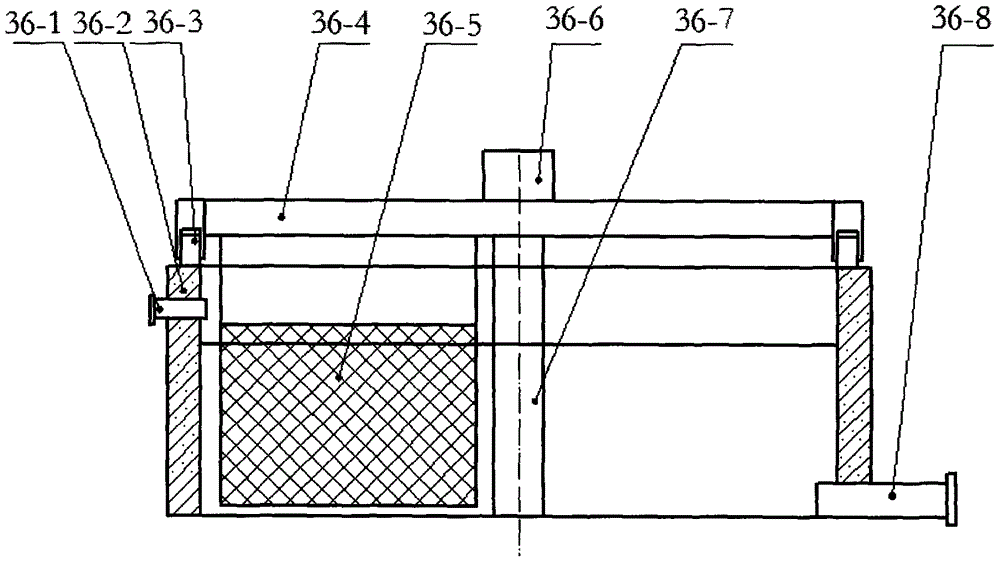

[0072] refer to figure 1 and figure 2 :

[0073] The present invention is achieved in this way. A device for treating low-concentration refractory organic industrial wastewater includes: a first valve 1 with a chuck joint, a first chuck 2, a first sealing gasket 3, a second chuck 4, a first Chuck joint 5, sewage inlet pipe 6, first cavity 7, intake elbow 8, third chuck 9, second gasket 10, fourth chuck 11, second valve 12 with chuck joint, The fifth chuck 13, the third sealing gasket 14, the sixth chuck 15, the seventh chuck 16, the fourth sealing gasket 17, the eighth chuck 18, the outer casing 19, the inner casing 20, the outer filter element 21, the second empty Cavity 22, inner filter element 23, filter cartridge 24, second chuck joint 25, ninth chuck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com