Telescopic belt conveyor

A telescopic belt conveyor and belt technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems that the direction of the carriage cannot be changed, the length cannot meet the requirements, and the height of the belt conveyor is high, so as to achieve compact structure, meet height requirements, and reduce height Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

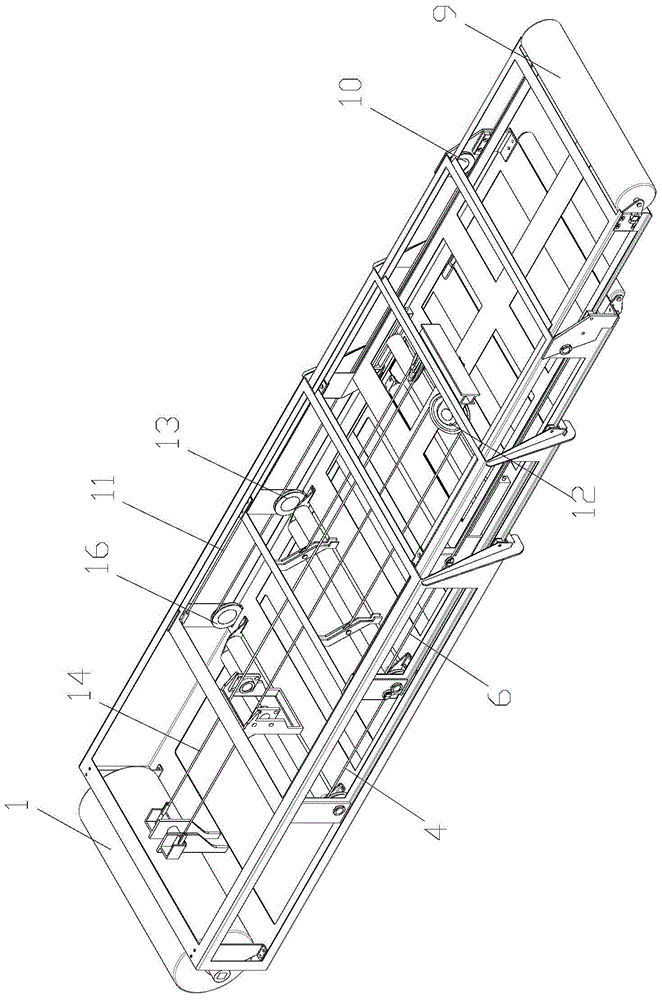

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown, a kind of telescopic belt conveyor of the present invention, it comprises basic arm 2, first telescopic arm 5, second telescopic arm 7, the 3rd telescopic arm 8, driving mechanism and belt transmission mechanism,

[0022] The belt transmission mechanism includes: a belt 14, an electric drum 1, a first redirecting drum 9 fixed on the front end of the third telescopic arm 8, a second redirecting drum 20 fixed on the front end of the second telescopic arm 7, and a second redirecting drum 20 fixed on the front end of the second telescopic arm 7. The third reversing roller 23 and the first adjusting roller 23A with the same shape at the front end of the telesc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com