Bicycle

A bicycle and frame technology, which is applied in the field of bicycle manufacturing, can solve the problems of not being able to drive the crankset and riding hard, and achieve the effect of convenient riding and easy exertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

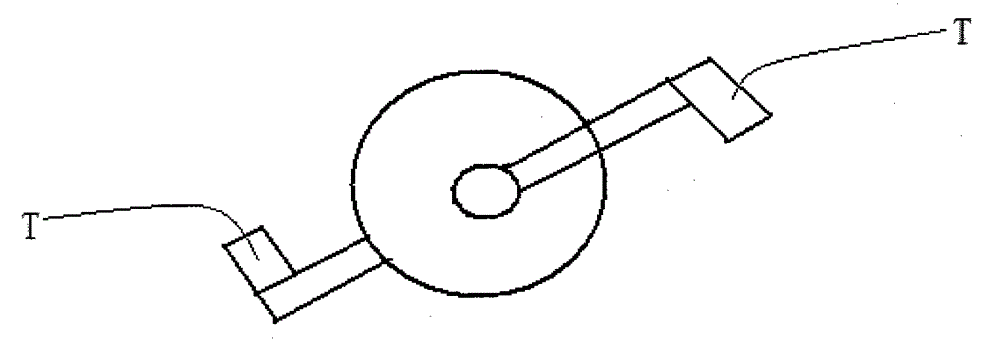

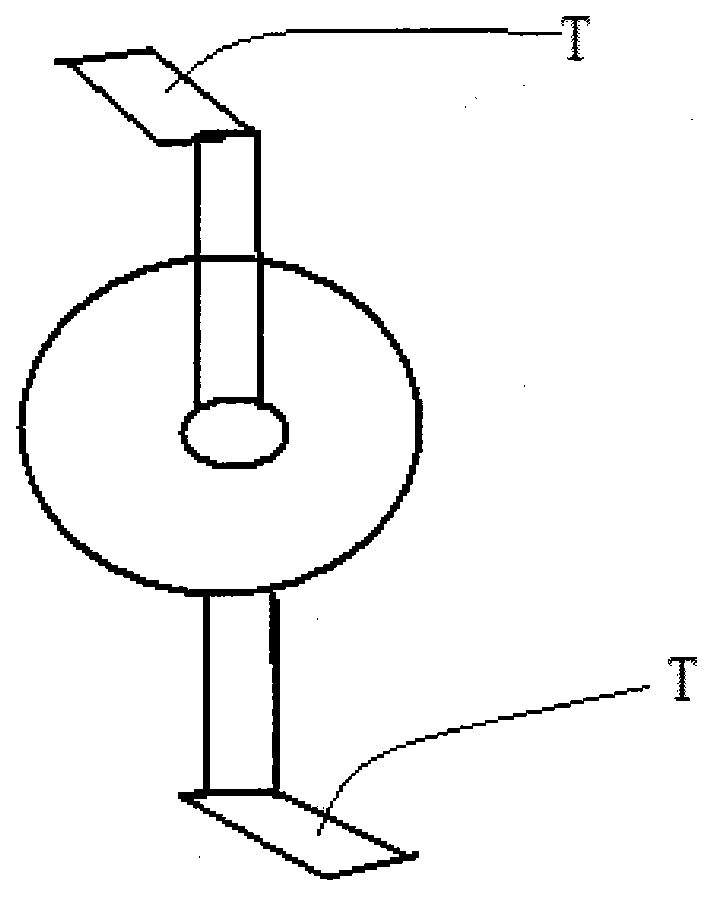

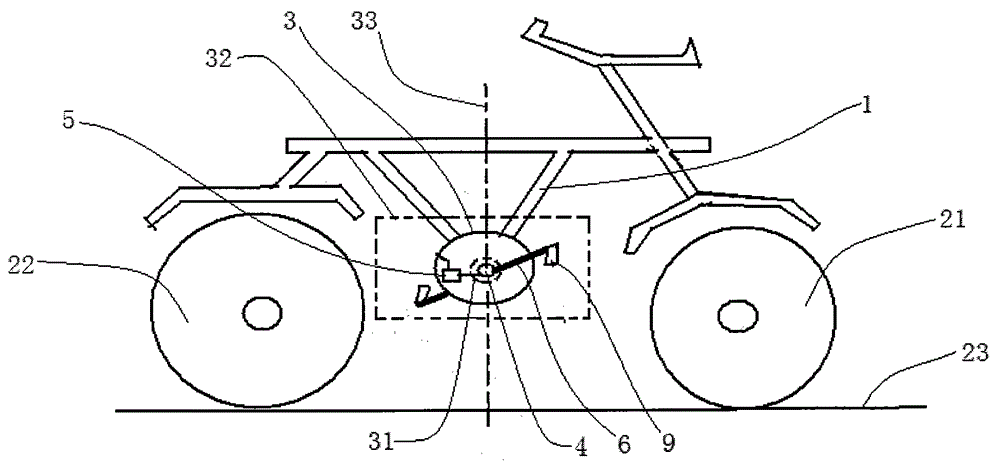

[0017] A bicycle, comprising a vehicle frame 1, a front wheel 21, a rear wheel 22, a crankshaft 3, and a rotating shaft 4, a clutch structure 5, and two connecting rods 6; the center of the crankshaft 3 is provided with a circular hole 31, and the crankshaft 4 runs through the round hole 31, the two ends of the rotating shaft 4 are respectively connected to the head end of a connecting rod 6, and the tail end of the connecting rod 6 is provided with a pedal 9; the plane formed by the extension of the tooth plate 3 is called vertical Face 32, the projection of two pedals 9 on vertical surface 32, wherein one is positioned at circular hole 31 one side, and another is positioned at the opposite side of circular hole 31; The straight line cut is called the horizon 23, and the straight line passing through the center of the tooth plate 3 and perpendicular to the horizon 23 is called the plumb line 33; the clutch structure 5 is arranged between the rotating shaft 4 and the tooth plat...

Embodiment 2

[0021] A bicycle, comprising a vehicle frame 1, a front wheel 21, a rear wheel 22, a crankshaft 3, and a rotating shaft 4, a clutch structure 5, and two connecting rods 6; the center of the crankshaft 3 is provided with a circular hole 31, and the crankshaft 4 runs through the round hole 31, the two ends of the rotating shaft 4 are respectively connected to the head end of a connecting rod 6, and the tail end of the connecting rod 6 is provided with a pedal 9; the plane formed by the extension of the tooth plate 3 is called vertical Face 32, the projection of two pedals 9 on vertical surface 32, wherein one is positioned at circular hole 31 one side, and another is positioned at the opposite side of circular hole 31; The straight line cut is called the horizon 23, and the straight line passing through the center of the tooth plate 3 and perpendicular to the horizon 23 is called the plumb line 33; the clutch structure 5 is arranged between the rotating shaft 4 and the tooth plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com