Plank cutting and edge trimming device

A technology for wood boards and base plates, which is applied in the field of wood board cutting edge trimming devices, can solve the problems of complex process, low processing precision, and inflexibility, etc., and achieves the effects of operator safety, good cutting effect and high safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

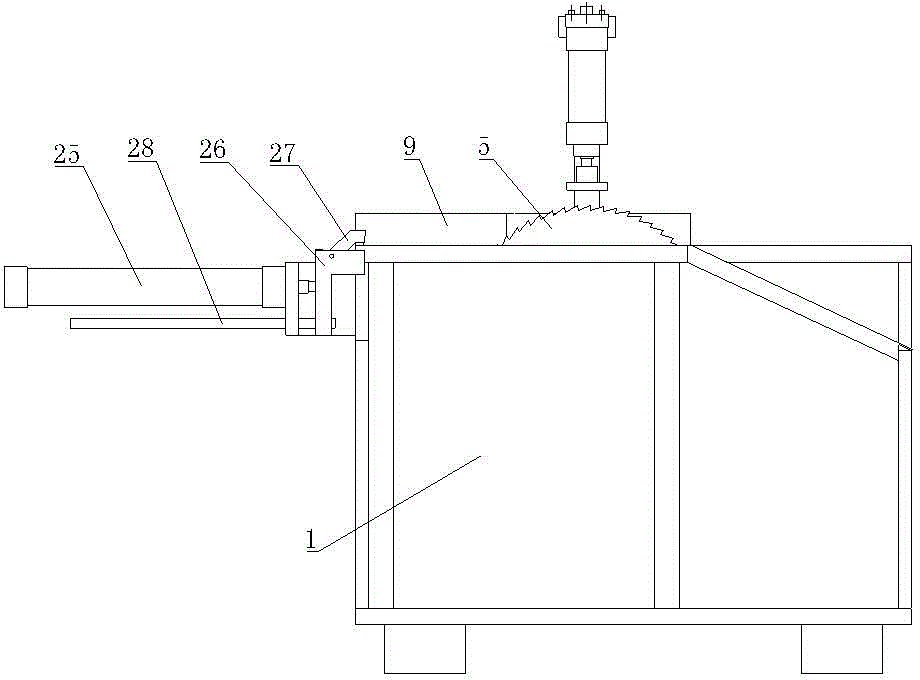

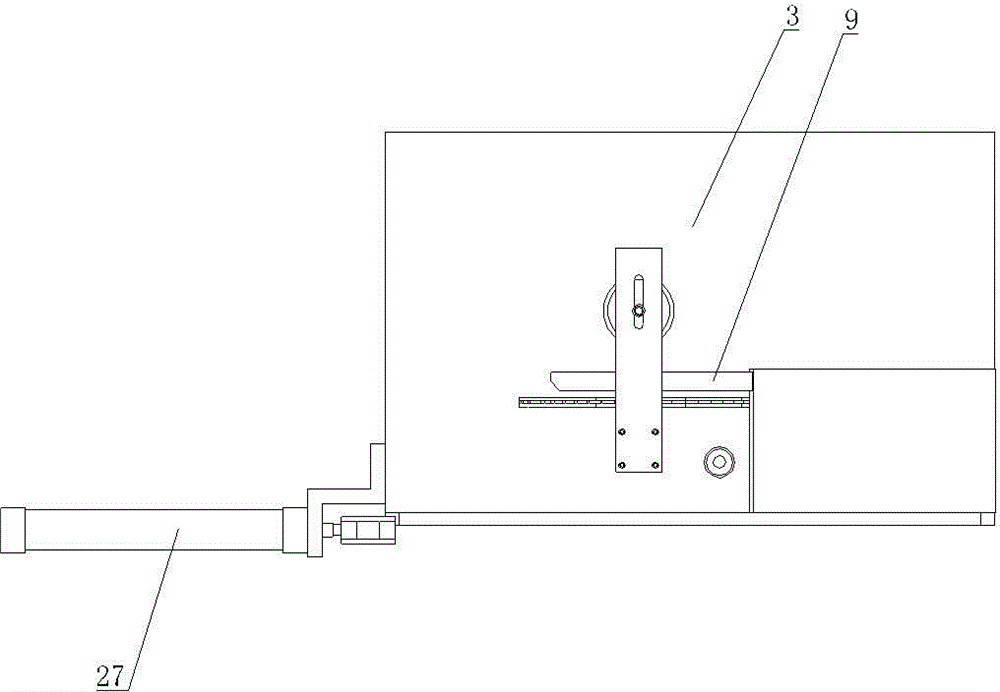

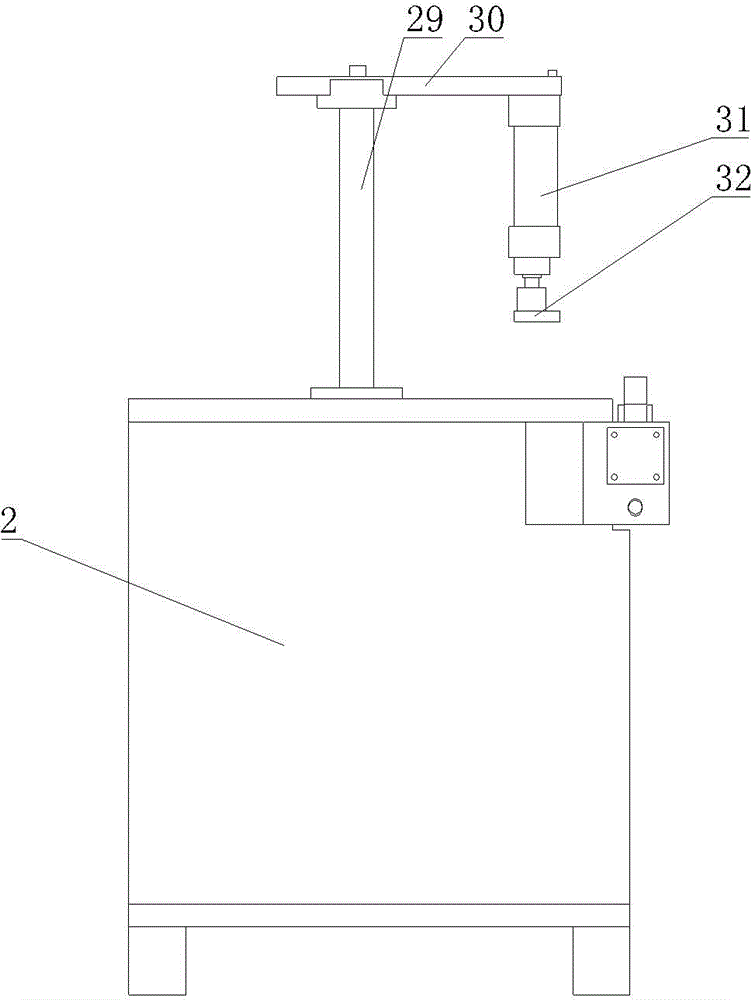

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , including a base 1, the base 1 includes a mounting box 2, a bottom plate 3 is arranged on the mounting box 2, a saw blade 5 driven by a motor 4, and a cylinder for lifting the saw blade 5 are arranged in the mounting box 2 (not shown in the figure ), the positioning cylinder 7 connected with the positioning block 6, and the bottom plate 3 are respectively provided with a saw groove 8 and a positioning hole 9 for the saw blade 5 and the positioning block 6 to pass through. Plate 9, on the outside of the base plate 3 corresponding to the limit plate 9 is also provided with a pressing mechanism, the rear end of the base plate 3 is also provided with a pushing mechanism, on the base 1, a rear slide plate 10 is provided on the rear side corresponding to the saw groove 8 , the rear end of the rear slide 10 is inclined downward;

[0022] The installation box 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com