A 3D printing sand core for core assembly

A 3D printing and sand core technology, which is applied in the field of 3D printing sand cores for high-strength core assembly and high-strength 3D printing sand cores, can solve the problems of complex production, single printing materials, and lack of strength improvement, etc. The effect of improving core strength, improving casting quality, and expanding adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples.

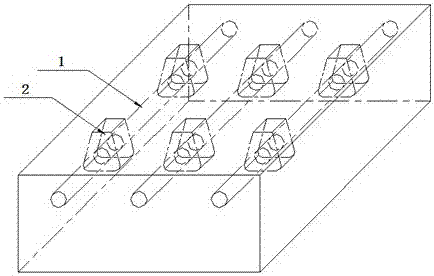

[0025] Such as Figure 1-2 As shown, the 3D printing sand core for core assembly in the present invention includes: core bone holes, sand filling holes, core bone, and resin sand, wherein a plurality of core bone cores are arranged in the sand core body at the upper part of the inner cavity of the sand core Holes, wherein, the interval between the buried core bone holes is determined according to the strength requirements, and the interval value is 100-500mm. The core bone hole extends horizontally in the sand core body, and a core bone is fixedly installed in each core bone hole; preferably, the core bone hole is parallel to the upper surface of the sand core, and has a distance of 0.5 to the core bone. A gap of -2mm ensures that the mandrel can be suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com