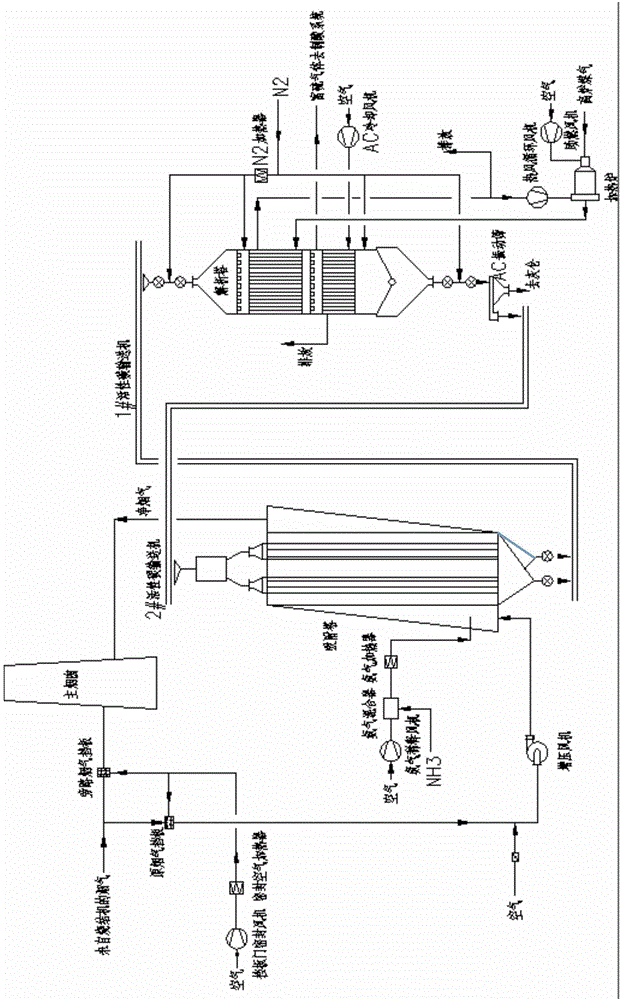

A flue gas desulphurization denitration method adopting ammonia-containing wastewater for flue gas temperature control and a device therefor

A technology for flue gas and wastewater, applied in separation methods, chemical instruments and methods, air quality improvement, etc., can solve problems such as increasing operating costs and increasing ammonia consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0118] The mixing device (M) used in the following examples includes an air pipeline (602), an ammonia pipeline (606), an air helical section (609), an ammonia helical section (610), a mixing section (612) and a mixing Gas outlet (616), wherein the ammonia pipe (606) is inserted (or extended into) the air pipe from one side of the larger diameter air pipe (602), then bent and along the axis of the air pipe (602) along the The air flow direction extends a certain distance L (it is for example 20-80%, more preferably 35-65% of the total length of the mixing device, such as L=0.2-2 meters, preferably 0.3-1.5 meters), the end of the ammonia pipeline (606) The section is an ammonia gas spiral segment (610), and the ammonia gas spiral segment (610) includes m helical ammonia passages separated by m longitudinally extending spiral plates (608) in the ammonia pipeline (606), in addition , the air spiral section (609) corresponding to the ammonia gas spiral section (610) comprises a sp...

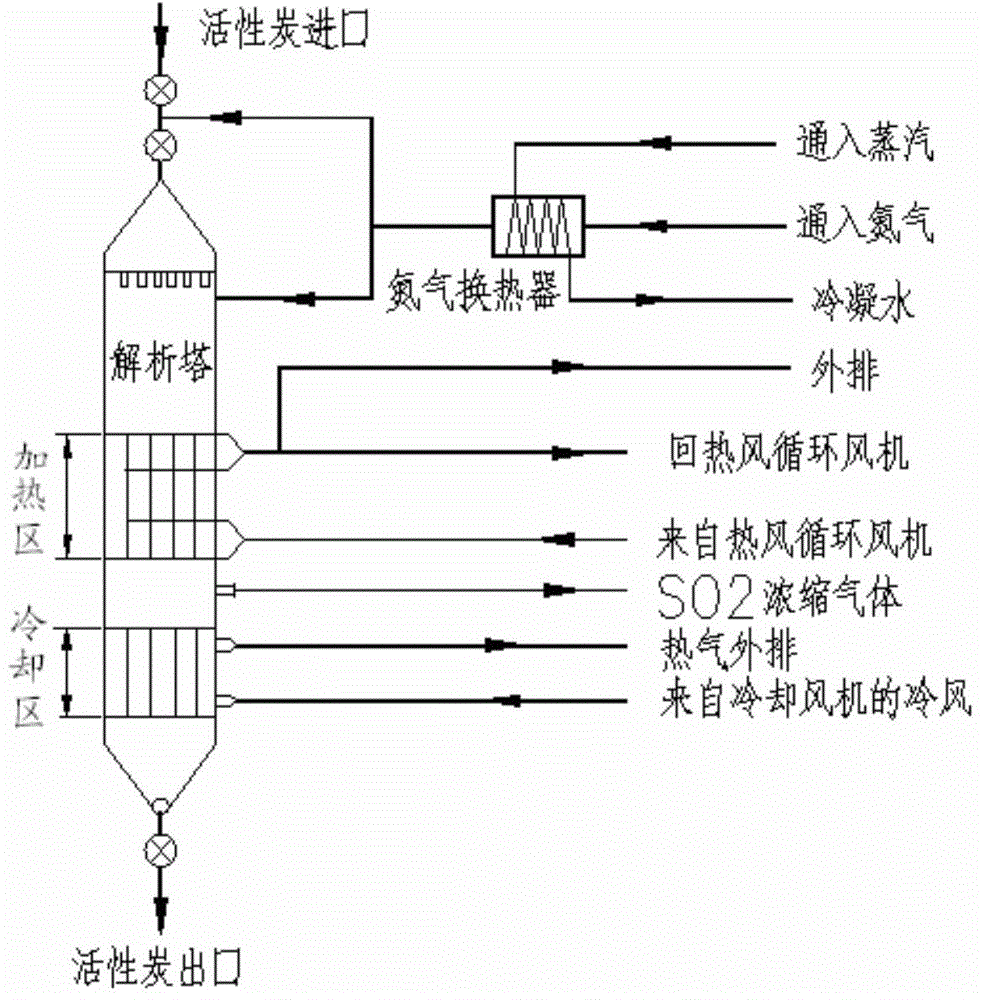

Embodiment approach 1

[0129] use Figure 2A , 2B and the flowsheet and adsorption column shown in 2C.

[0130] Activated carbon adsorption tower device includes

[0131] 1) adsorption tower (1),

[0132] 2) The raw flue gas conveying flue (102) upstream of the flue gas input port of the adsorption tower, wherein a cold air inlet is provided on the upstream position P1 of the flue, and a process water nozzle is provided on the downstream position P2 of the flue (P2),

[0133] 3) An optional (ie optional) air cooler (509) connected to the cold air inlet at position P1,

[0134] 4) The process water delivery pipeline (508) connected with the process water nozzle (P2) on the P2 position, a branch is branched from the pipeline 508 and connected to the ammonia-containing waste water storage tank in the acid production area, so as to be transported from the storage tank Ammonia-containing waste water to process water nozzle (P2),

[0135] 5) A booster fan (514) located between the P1 and P2 position...

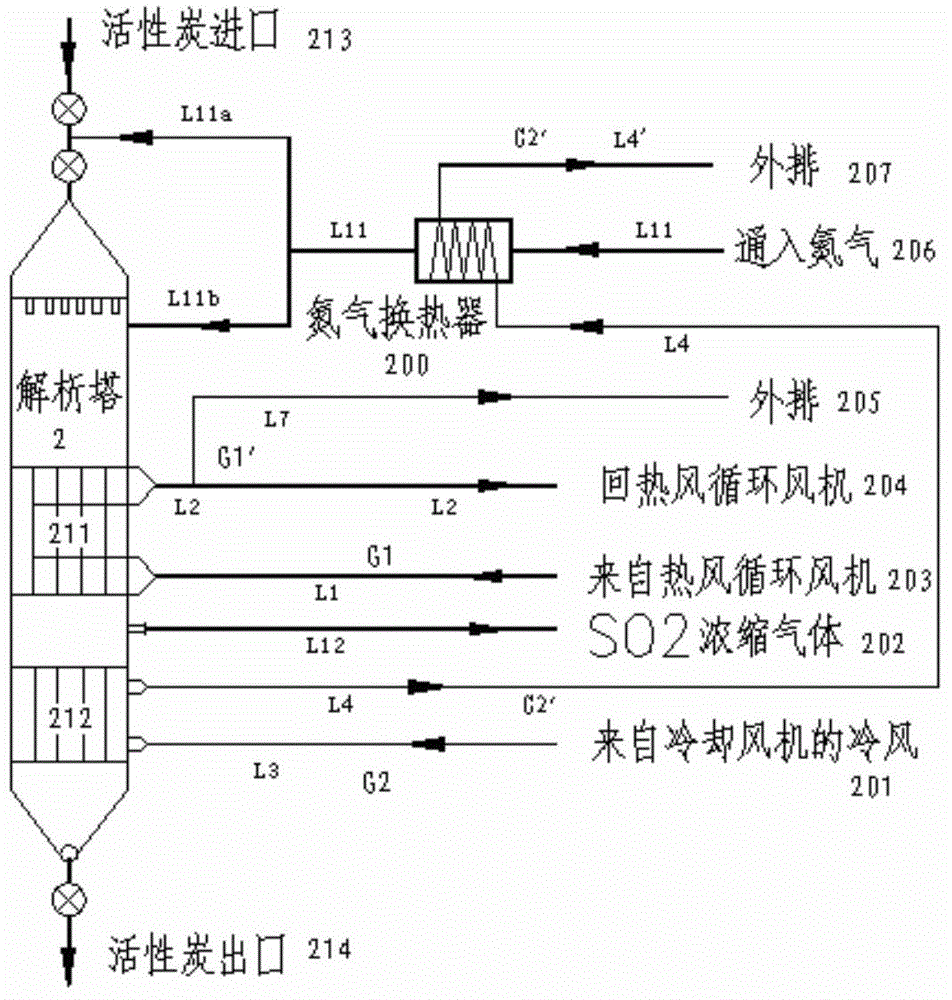

Embodiment approach 2

[0161]Repeat embodiment 1, only: a part (such as 4-25vol%, preferably 6-20vol%, more preferably 8-15vol%) of the above-mentioned externally exhausted hot air (G1 ') is delivered to the nitrogen heat exchanger (100) and nitrogen Indirect heat exchange is performed to heat the nitrogen, and the nitrogen is heated to 105-155°C (preferably 110-150°C, more preferably 115-140°C). Then, the cool air (G2') subjected to heat exchange is discharged. And, likewise, the ammonia-containing waste water produced in the acid production zone replaces the above-mentioned process water or replaces a part of the above-mentioned process water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com