Adsorption method for purifying asphalt fume and practical purifier

A technology for asphalt flue gas and purifier, which is applied in chemical instruments and methods, separation methods, and filtration of dispersed particles, etc., can solve the problems of uneven use of adsorbent adsorption capacity, poor operating conditions, and high labor intensity of adsorbents. The effect of changing the working environment and conditions and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

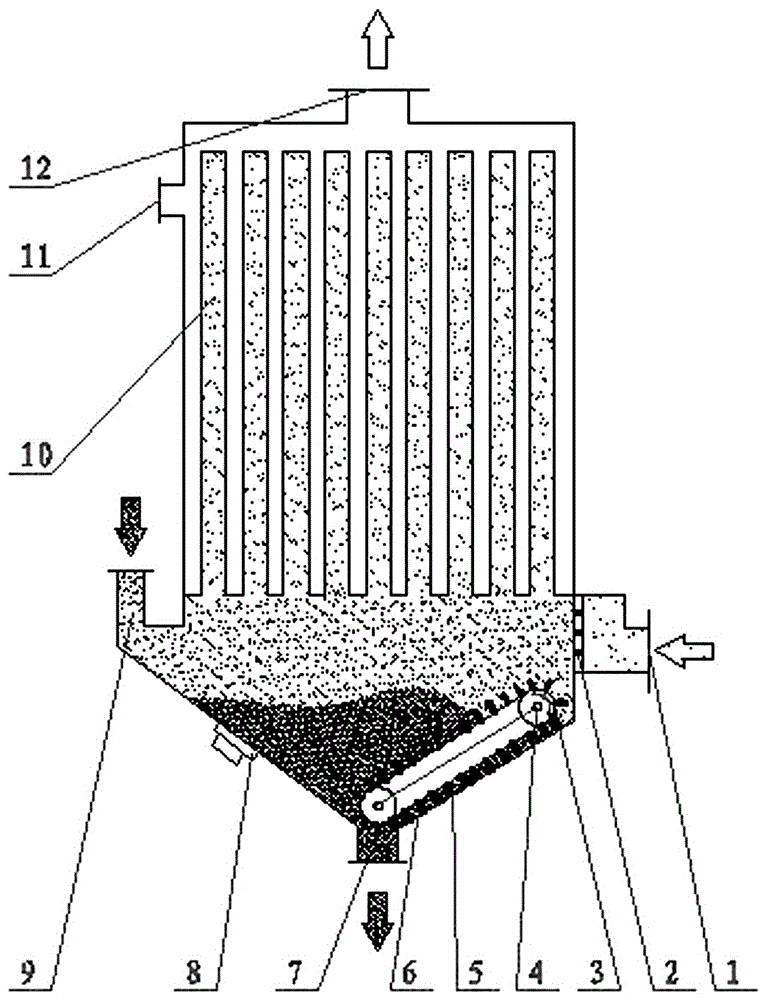

Image

Examples

example

[0020] Example: A carbon factory in Jiaohe City, Jilin Province used a double-layer planar adsorption bed purifier to treat the asphalt fume of the forming air machine, and the emission concentration after purification was 50mg / m 3 the following. However, its floor area (including the necessary maintenance area) reaches 45M 2, , in the treatment of flue gas flow 3000M 3 / H, the coke adsorbent needs to be replaced once a week, and the production needs to be stopped for 6 hours during the replacement, and it can only be completed by the uninterrupted continuous operation of four people. And after adopting the present invention, its floor area (including the necessary maintenance area) is only 18M 2 , Although the coke adsorbent is also replaced once a week, but only one person is required to control the valve of the adsorbent's loading and discharging outlet during the replacement, and it can be completed within 15 minutes of shutting down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com