Differential speed centrifugal oil fume separator

An oil fume separator and circle center technology, which is applied in the field of differential centrifugal oil fume separators, can solve the problems that the blades of the oil fume separator are easy to fall out from the center plate, the service life of the motor is short, and the oil fume purification effect is low, and the weight is achieved. The effect of light weight, improved purification efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

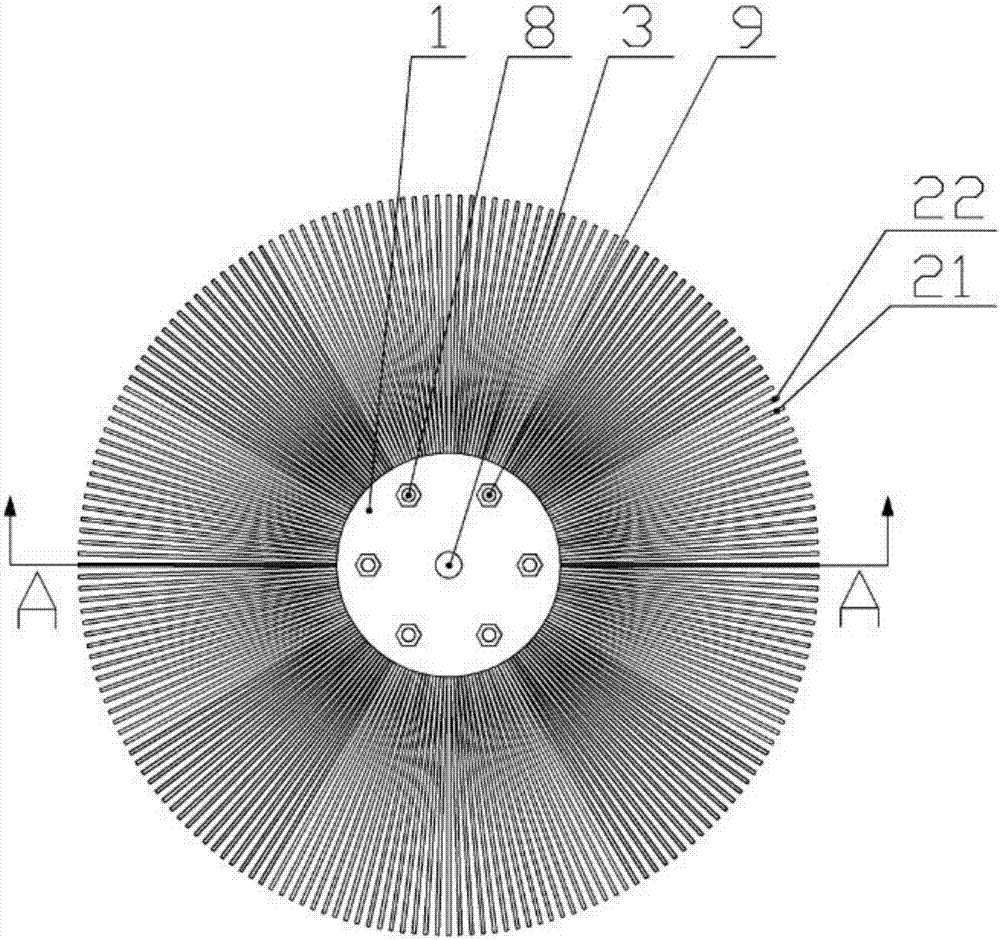

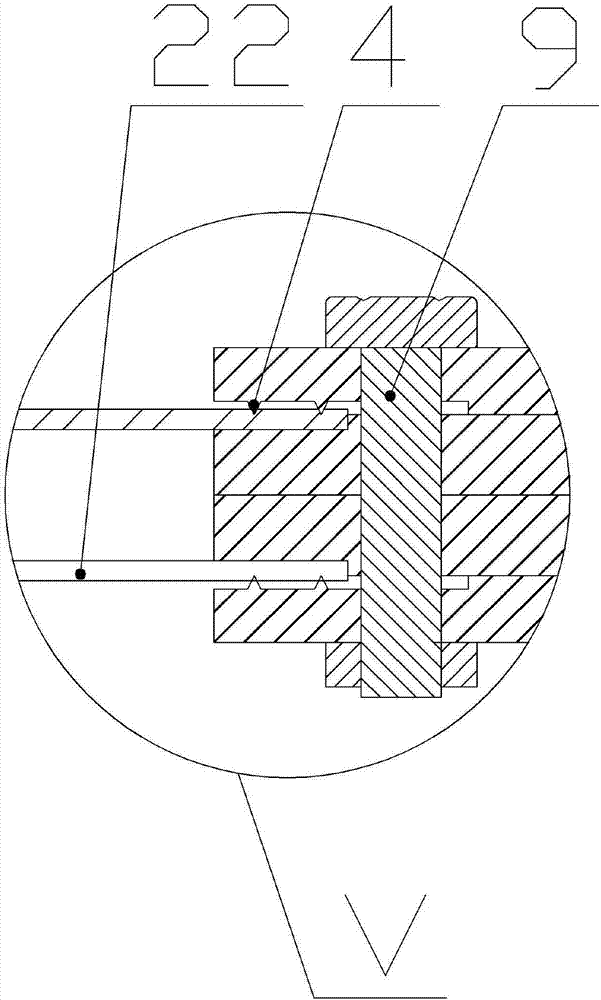

[0033] Refer to attached figure 1 , the present invention includes a central disk 1 and several blades 2, the center of the central disk 1 is provided with a mounting hole 3, the mounting hole 3 is used to install the oil fume separator on the motor; one end of several blades 2 is evenly fixed on the central disk 1 In the side wall of the central disk 1, the other ends of several blades 2 are freely extending in a divergent shape, and several blades 2 are distributed in at least two layers on the side wall of the central disk 1, and the blades 2 on each layer are connected to those on the adjacent layer. The blades 2 are arranged alternately in sequence. Blades 2 that are not on the same layer are alternately arranged in turn so that the blades 2 on two adjacent layers form a time difference, so that the oil fume can be separ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com