Elastic coupling device for connecting two drive shafts

A transmission device and actuator technology, which is applied to transmission devices, clutches, electric clutches, etc., can solve problems such as high friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

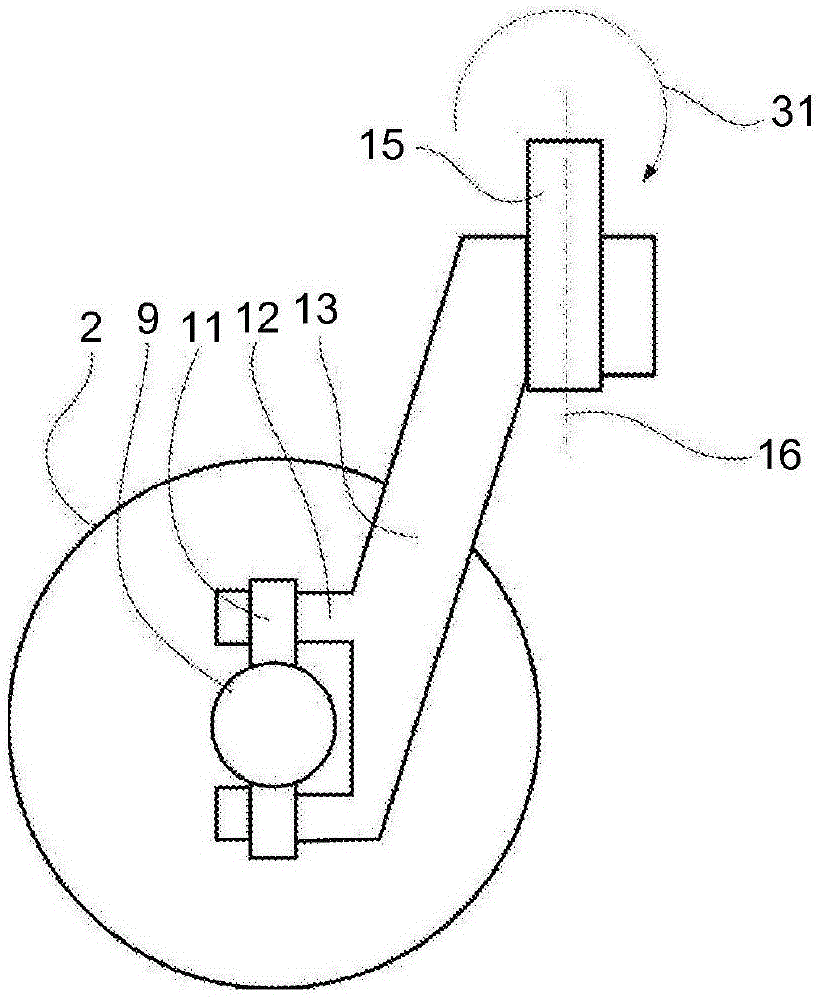

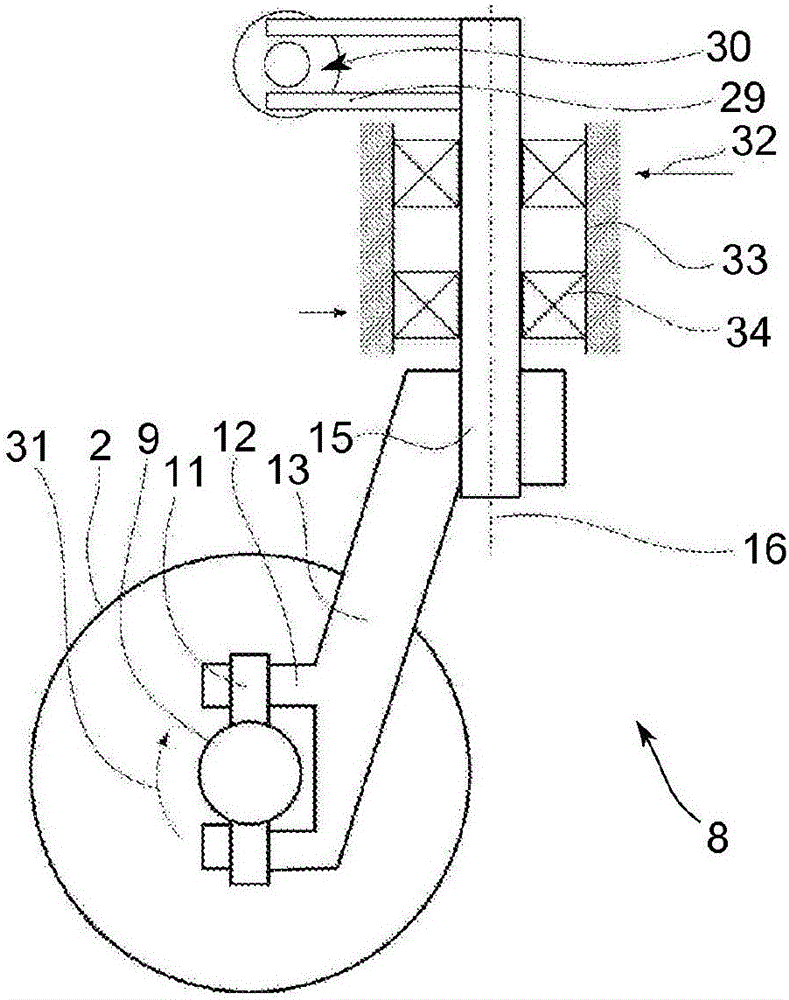

[0034] exist figure 1A first operating device 1 according to the invention is shown in . The actuating device 1 is dimensioned and provided for use in a clutch, such as a dual clutch, of a motor vehicle. The actuating device has an electromechanical actuator 2 . The actuator 2 contains a screw 3 which can be set in rotational motion by an electric motor. The screw 3 engages into a motion conversion transmission 4 . The motion conversion gear 4 is designed as a planetary roller gear (PWG) and has the reference numeral 5 . The planetary roller drive is connected / coupled to the pressure sleeve 6 in a pressure and / or tension transmission manner. The pressure sleeve 6 is coupled via a joint unit 7 to a clutch adjusting device 8 . The clutch adjustment device is especially clear in image 3 and 4 visible in .

[0035] back to figure 1 , it should be clarified that the planetary roller transmission (PWG) (5) is formed as a planetary roller transmission with accurate pitch. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com