Flame retardant and flame retardant polyurethane resin composition

一种阻燃剂、原料组合物的技术,应用在聚氨酯树脂组合物,阻燃性聚氨酯树脂组合物,阻燃剂领域,能够解决产生卤化氢等问题,达到变形特性优异、优异可回收性、焦烧特性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0228] Hereinafter, the present invention is described in further detail by showing synthesis examples, reference examples, examples, and comparative examples.

Synthetic example 1

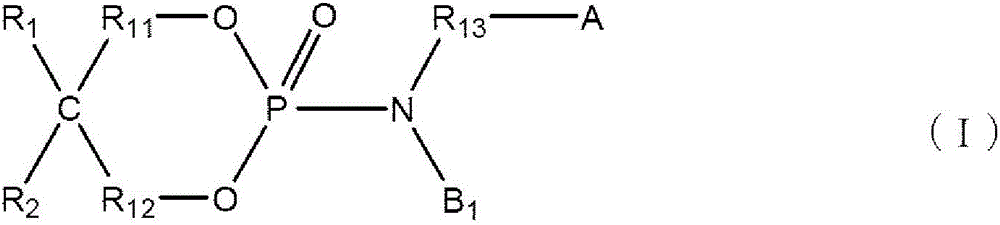

[0231] Synthesis of formula (1) compound

[0232] [chemical formula 10A]

[0233]

[0234] As a first step reaction, 312.6 g of neopentyl glycol (3.00 mol) and 109.5 g of 1,4-dioxane were filled into a tank equipped with a stirrer, a thermometer, a return line connected to a hydrochloric acid recovery unit, an absorber, 1L four-necked flask with dropping funnel and heating device. The resulting liquid was heated to 50°C. Subsequently, 460.5 g (3.00 mol) of phosphorus oxychloride was added thereto over 2 hours while maintaining the reaction temperature at 45 to 55°C. After the addition was complete, the generated hydrochloric acid was collected while the mixture was further stirred at 80° C. for 1 hour, followed by dehydrochlorination at 80° C. and a low pressure of 80 kPa for 3 hours, thereby obtaining 662.8 g of a white slurry.

[0235] 100.6 g of the above white slurry obtained in the first reaction step of Synthesis Example 1 and 214.3 g of 1,4-dioxane were charged in...

Synthetic example 2

[0237] Synthesis of formula (4) compound

[0238] [chemical formula 10B]

[0239]

[0240] According to the same method as in Synthesis Example 1 except that 15.6 g (0.26 mol) of ethylenediamine was used instead of piperidine, 71.6 g (yield 77.4%) of a solid was obtained. Phosphorus content percentage: 17.3% by weight. Nitrogen content percentage: 7.8% by weight. The obtained flame retardant compounds were used in the following Reference Examples and Examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal degradation temperature | aaaaa | aaaaa |

| thermal degradation temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com