Constant volume type clean coal combustion device

A coal combustion and clean technology, applied in the direction of combustion methods, combustion equipment, solid fuel combustion, etc., can solve the problems of the reduction of heat intensity of the volume of the combustion chamber, the emission of flue gas pollutants due to heat loss, and the increase of the volume of the combustion chamber, etc., to achieve the principle Easy to understand, simple structure, compact layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention will be further described below in conjunction with the accompanying drawings.

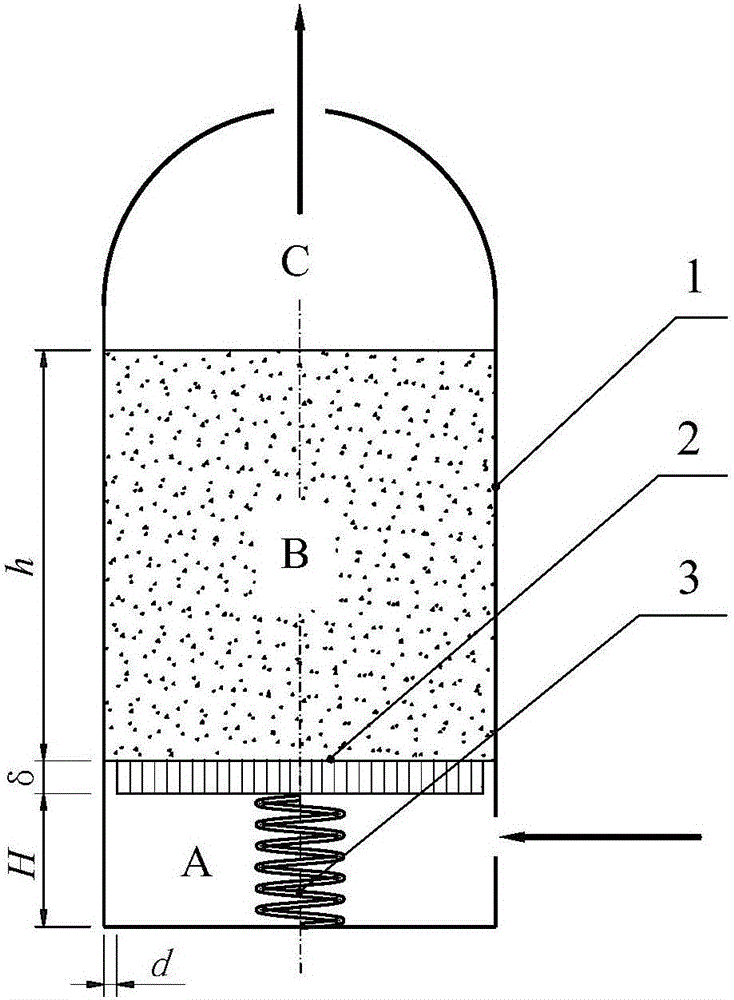

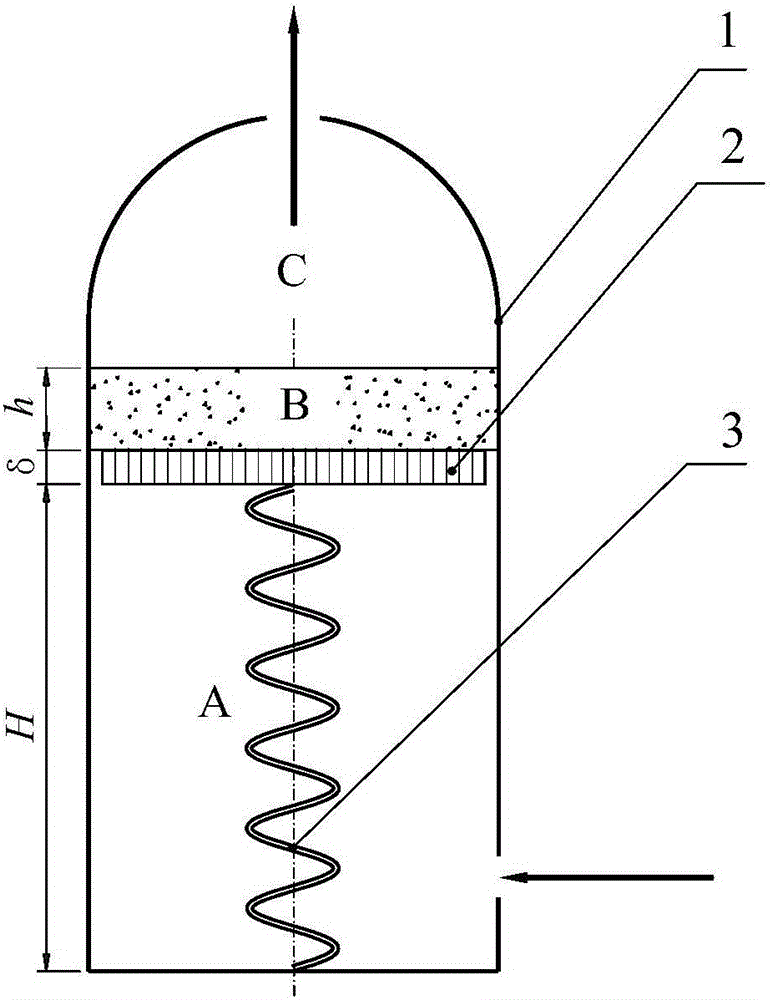

[0014] as attached figure 1 As shown, the constant-volume clean coal combustion device mainly includes a furnace inner wall 1, a furnace bar 2 and a spring 3. The spring 3 is vertically arranged, the top of the spring 3 is welded to the bottom surface of the furnace bar 2 and supports the furnace bar 2, so that the furnace bar 2 remains horizontal, and the bottom of the spring 3 is welded to the top surface of the furnace inner wall 1 bottom plate. The bottom plate of the furnace inner wall 1, the furnace bar 2 and the spring 3 are made of weldable metal.

[0015] The furnace inner wall 1 side wall is a vertical side wall. The side wall of the furnace inner wall 1 can be a vertical cylinder, a vertical square cylinder or other vertical irregular cylinders, and the horizontal cross-sectional area of the furnace inner wall 1 is constant.

[0016] The grate 2 is an integral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com