Method for optimizing engine torque based on intake pressure waves

A technology of engine torque and intake pressure, applied in engine components, engine control, combustion engines, etc., can solve problems such as accelerating combustion rate, accelerating air and fuel vapor mixing speed, accelerating gas flow, etc., to improve the inflation coefficient, optimize Pressure wave maximum value, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

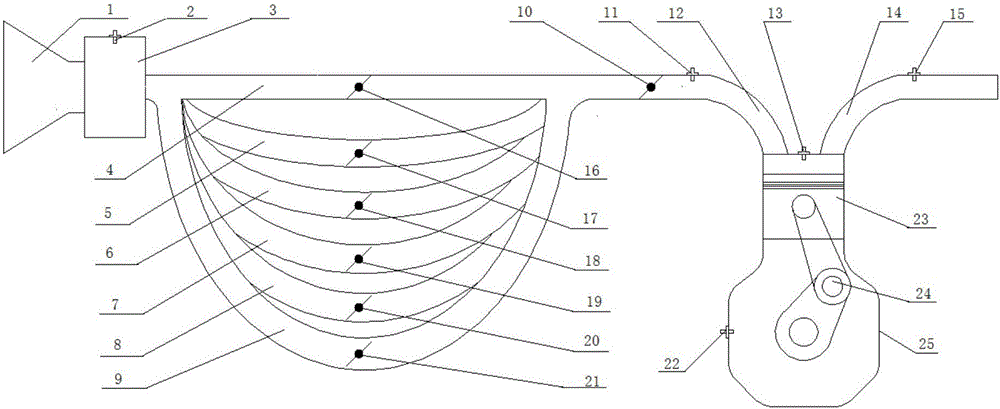

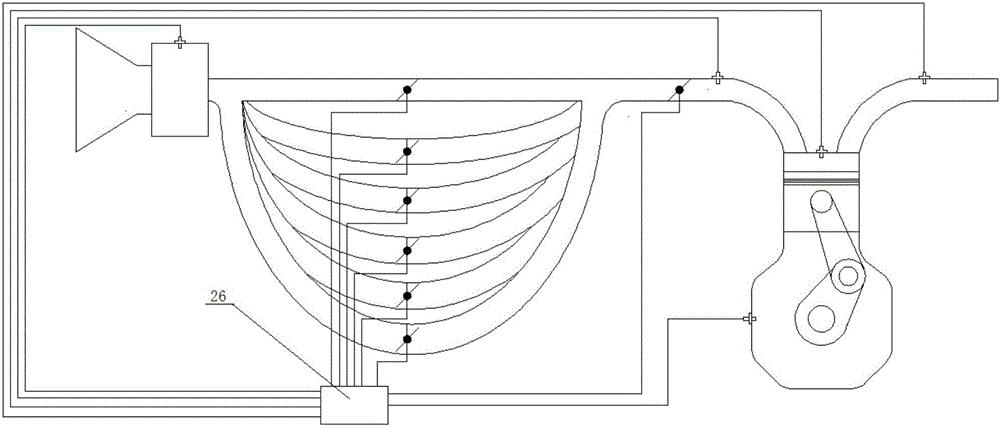

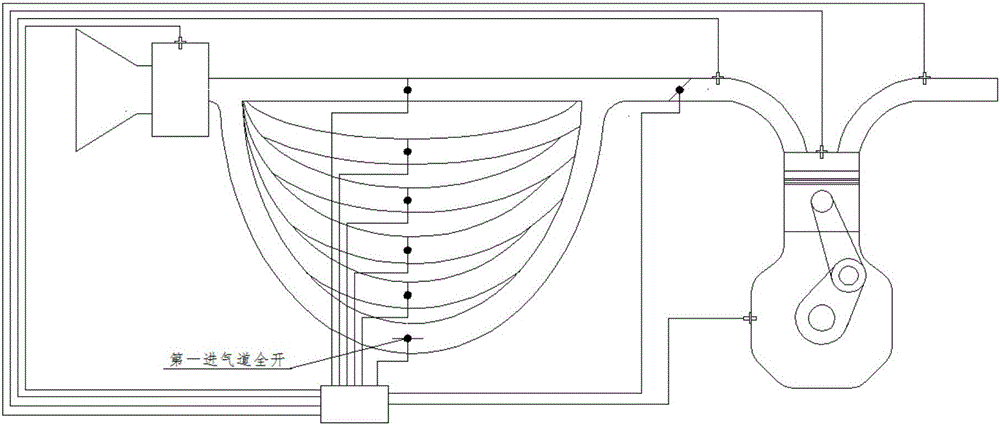

[0023] The following will be combined with Figure 1-Figure 8 The technical solution of the invention is described in detail.

[0024] Such as figure 1 , 2 As shown, a device for optimizing engine torque based on intake pressure waves of a motorcycle engine includes: intake port 1, air filter sensor 2, air filter 3, intake straight round pipe 4, fifth intake Air semi-elliptical tube 5, fourth intake semi-elliptical tube 6, third intake semi-elliptical tube 7, second intake semi-elliptical tube 8, first intake semi-elliptical tube 9, throttle position sensor 10, intake air Road sensor 11, intake port 12, spark plug 13, exhaust pipe 14, exhaust pipe sensor 15, air intake straight circular pipe control valve 16, fifth air intake semi-elliptical pipe control valve 17, fourth air intake semi-elliptical pipe Control valve 18, third intake semi-elliptical tube control valve 19, second intake semi-elliptical tube control valve 20, first intake semi-elliptical tube control valve 21,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com