Raw material storing device for spinning

A storage device and raw material technology, applied in the textile field, can solve the problems of increased labor costs, large area of raw materials, moisture in raw materials, etc., and achieve the effects of moving equipment quickly and accurately, reducing labor intensity, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention;

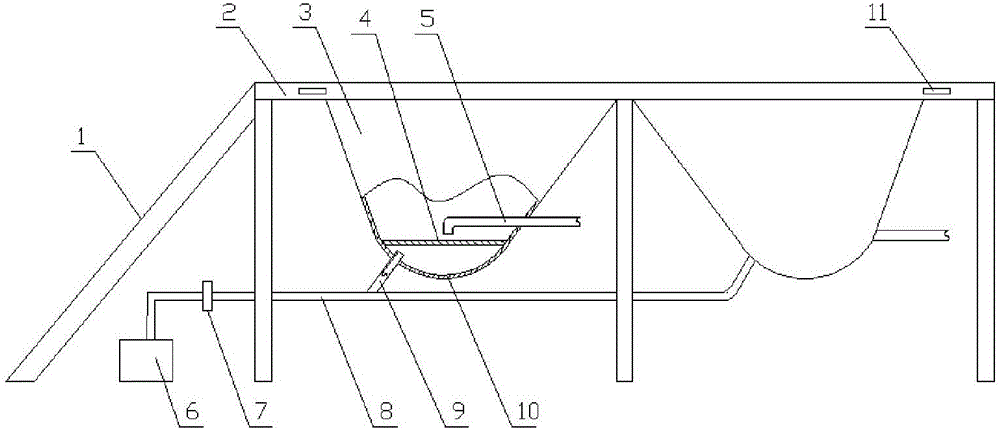

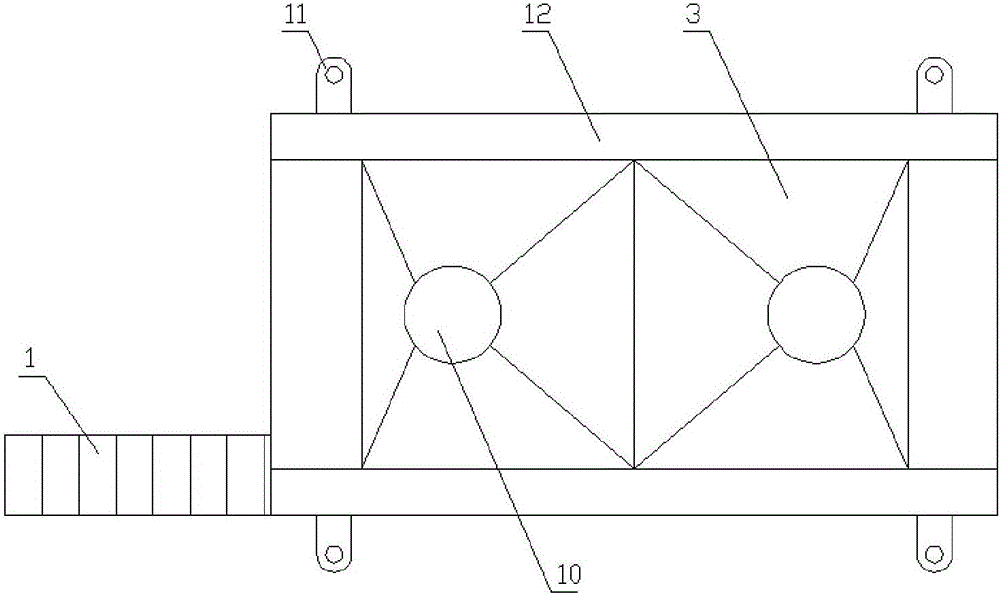

[0020] like figure 1 , figure 2 As shown, the structure of this kind of textile raw material storage device includes a frame 2; the inside of the frame 2 is provided with several bucket bodies 3, the upper surface of the bucket body 3 is flush with the upper surface of the frame 2, and the bucket body 3 is Inverted trapezoidal structure, several bucket bodies 3 are used to store different raw materials during use; the bucket body 3 is divided into a storage chamber (not shown in the figure) and a head high pressure chamber 10 by a fluidized bed 4, and the head high pressure chamber 10 is used. The high-pressure gas in the cavity 10 passes through the fluidized bed 4, so that the raw materials in the storage cavity at the upper end of the fluidized bed 4 are fluidized; one side of the bucket body 3 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com